2

Assembly Tips

1) To remove the parts from the original board, carefully bend the parts out to break the small

sliver of wood that is holding them in place. If necessary, use a knife to free any pieces that were

not completely scored by the laser. Remove any paper or tape from the back of the pieces.

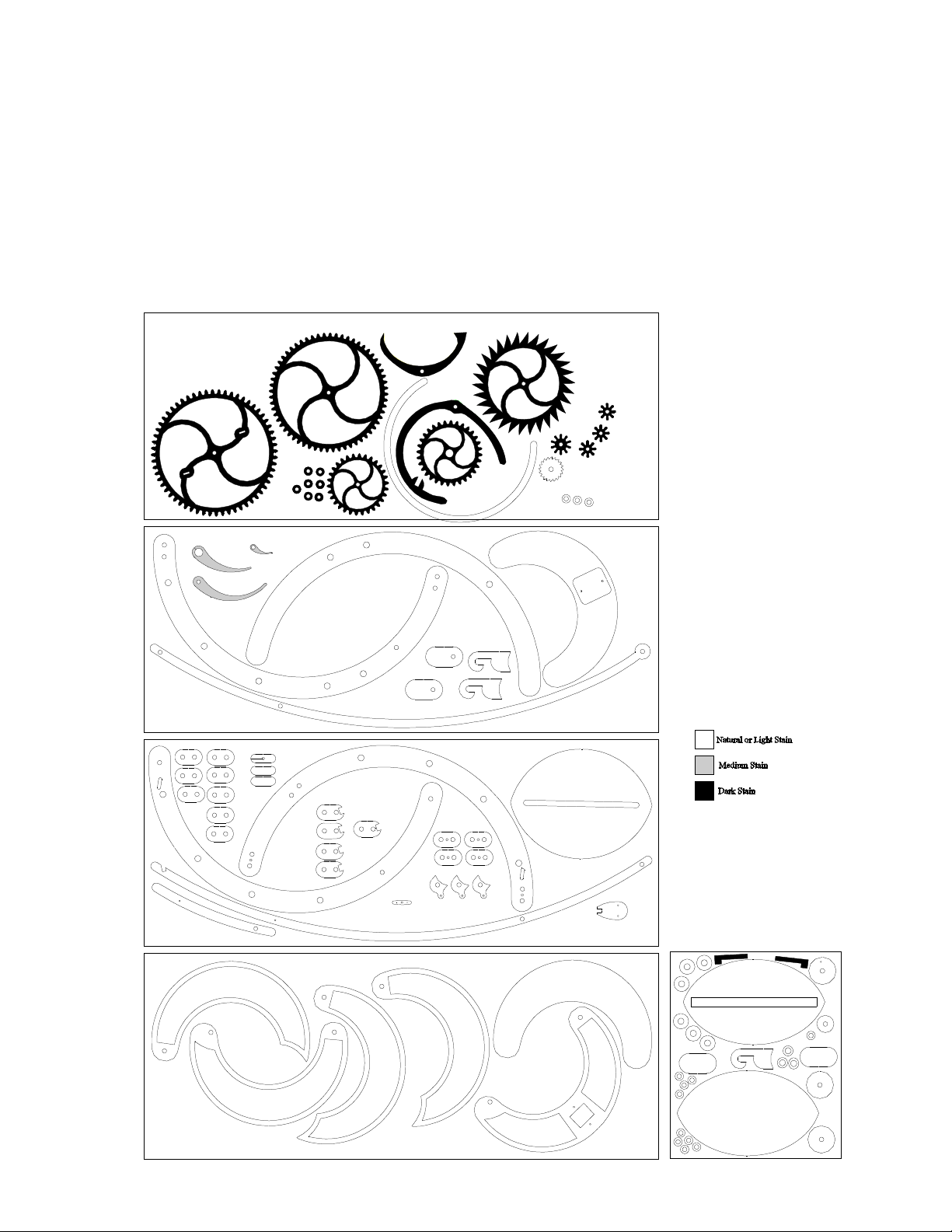

2) You may stain your clock if desired. See the Stain Chart on the next page for a suggested

color scheme. Although it is possible to do all the staining after the clock is assembled (the clock

is easily disassembled), you may find it easier to stain the gears prior to assembly. Since a finish

can hinder glue bond, wait to apply finish to the remaining pieces until the components have

been glued together (suggested sequence for sanding and finishing is included in the step by step

instructions). If you choose to apply a varnish, avoid getting varnish on the contact faces of

the gear teeth and escape lever.

3) A few components require gluing. Glued parts should be clamped while the glue cures.

4) Follow the instructions in order. Carefully complete one step before moving on to the next.

5) Some of the parts might benefit from some light sanding, especially at the breakaway points

where the pieces were attached to the original board. Do not sand the mating surfaces of the gear

teeth. Note that the backsides of some pieces will show residue from the laser cutting operation.

A light sanding will remove this residue, although for nearly all parts this is not necessary

because the residue will not be visible once the clock is assembled. If desired, the edges of the

frame pieces can be sanded to remove the residue left by the laser. The assembly instructions

indicate at what point the various pieces should be sanded.

6) It will be beneficial to lubricate a few points with graphite (pencil lead). These points include

the portions of the arbors that spin in the bearings and the contact faces of the escape lever.

7) Some of the parts fit together tightly. It may be necessary to gently tap them together with a

hammer. (Plywood thickness can vary slightly. If the fit seems too tight, some light sanding may

be necessary to insure a proper fit).

8) Once the clock is a assembled and mounted, there will likely be some adjustments required to

get the clock running properly. Follow the suggestions in the ‘Adjusting and Regulating’ and the

‘Troubleshooting’ sections of the instructions.

9) Take your time and enjoy the process!