Jigsaw EN

10

5. DUST COVER

When operating your jigsaw the dust cover

must be closed to allow the dust extraction

system to work efficiently.The dust cover can

be moved to improve access for cleaning,

blade fitting, etc (See Fig. C).

6. BLADE FITTING

You can only use the blade type shown in Fig

D.To open the blade holder rotate the ring

clockwise (Jigsaw upside down) and hold in

position (See Fig. E).Then fully insert the blade

into the blade holder slot with blade teeth

facing forward and release the ring, which will

self rotate and clamp over the top of the blade.

Push the blade into the blade holder again to

ensure it is locked in position. Ensure the edge

of the blade is located in the groove of the

blade guide (See Fig. F).To remove a blade,

holds the blade and rotate the blade holder

ring clockwise then lift out the blade (blade

could be spring ejected).

WARNING: Blade teeth are very

sharp. For best cutting results ensure

you use a blade suited to the material and cut

quality you need.

7. PARALLEL GUIDE FIXTURES

Slide the parallel guide (7) arm through

both fixtures to achieve the required cutting

distance and tighten both screws to lock into

position.

8. ROLLER GUIDE

Ensure the blade is located and runs smoothly

in the groove.(See Fig. F) Otherwise the

pendulum function will not work correctly and

the blade will not be supported during cutting.

9. PENDULUM ACTION CONTROL

The pendulum action varies the forward

cutting angle of the blade for increased cutting

efficiency.This can also be adjusted during

no load running. Refer to the chart 2 for more

details. Do not use excessive blade force when

cutting with the pendulum action.The blade

cuts on the upward stroke only (See Fig. G).

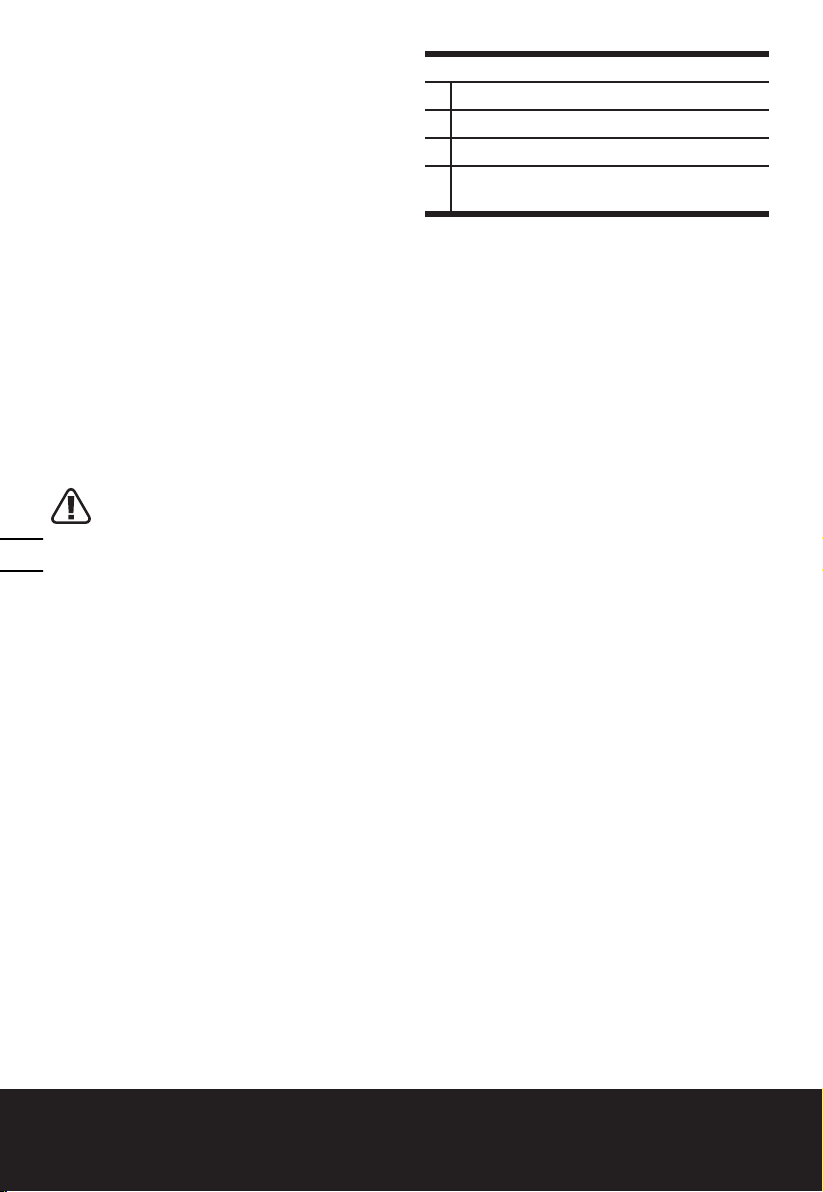

Chart 2

1Thin materials. Fine cuts.Tight curves.

2Hard materials, (e.g. steel & chipboard)

3Thick materials (e.g. wood) & plastic

4Fast cuts (e.g. softwood). Cutting in the

direction of the wood grain.

10. BASE PLATE

Adjusting the angle of the base plate (13)

enables bevel cutting.The base plate must

always be held firmly against the materials

being cut to reduce saw vibration, blade

jumping or blade breakage.

11. PLASTIC FOOT PLATE PROTECTION

Your tool is equipped with base plate

protection that protects finer surface.

To attached, hook the protection over front of

base plate and snap into place at the rear of

base plate.

12. BASE PLATE ANGLE ADJUSTMENT

Use an allen key (5). First loosen the bolts

securing the base plate and pull the base

plate out of the slots (See Fig. H). For preset

angles rotate so the lines of the angle on the

base plate and angle plate (9) superposition

at the desired angle (0, 15, 30, 45) (See Fig. I).

For other bevel angles, rotate to your desired

angle (use a protractor scale). Following one

of the above procedures, hold the base plate

in position and firmly tighten the bolts to

clamp the base plate at that angle. Finally,

check the angle and ensure the base plate

is firmly clamped.The angle markings on

the base plate are accurate for most general

purposes but it is recommended for accurate

work to set the angle with a protractor and

make a test cut on other material.

13. VACUUM ADAPTER

The adapter (6) rotates anti-clockwise inside

the housing and locks in position by a groove

inside the housing (See Fig. J & K).The

adapter must then be connected to a suitable

external dust extraction machine.