9

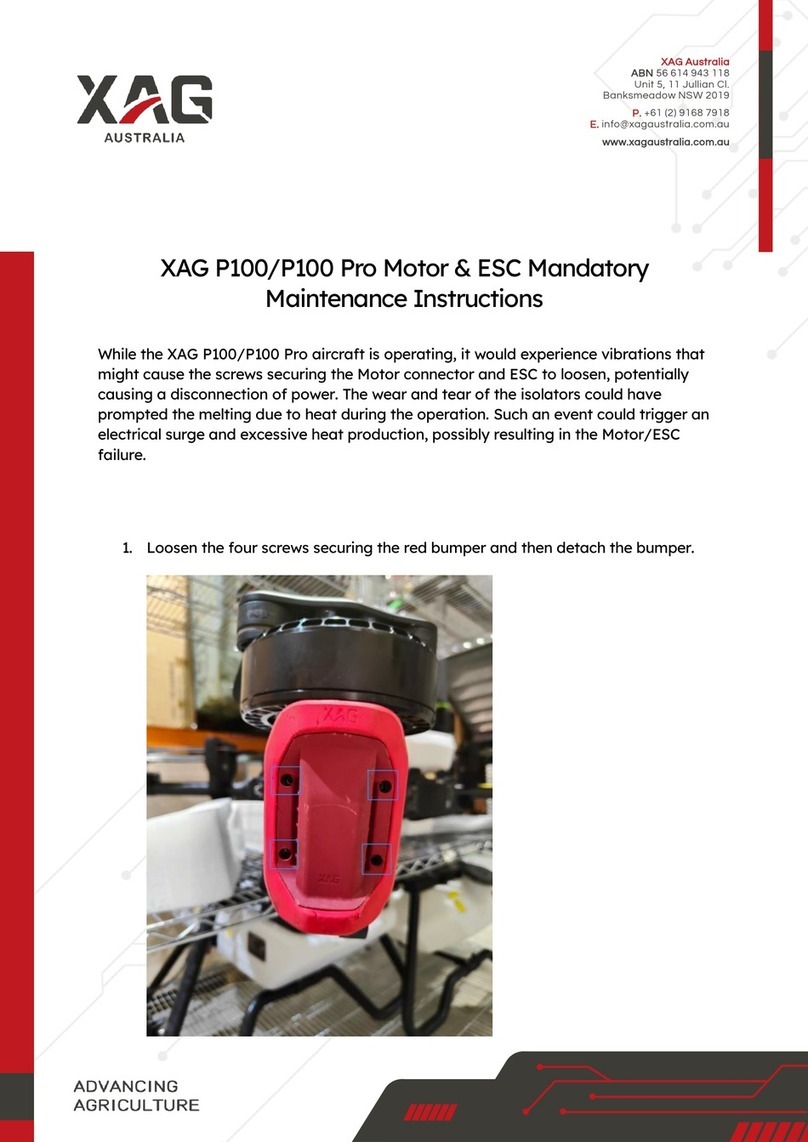

🔧Disassemble:

Nozzles

1. Drain all liquid and residues from

the liquid tube and unplug the

corresponding liquid tube.

Uses a 2.5 screwdriver to remove

the 4 screws securing the Nozzle.

The screws using M3*8*6

Hexagon socket combination

screw here.

2. Disconnect the nozzle connector

and remove the nozzle.

I. Prevent liquid tubefrom bending.

II. Avoid liquid or foreign matter when connecting or disconnecting the nozzle connector .

III. Ensure the shock-absorbing screws are intact and not damaged, DO NOT install with force.

The shock-absorbing screws using M3*8 Screw Dampener here.

•After the reassembly of the nozzle is completed, perform a manual spray test to confirm

the corresponding nozzle is working normally.

IMPORTANT:

P20/P30 2019 Nozzle *1 SKU-05-002-00546

M3*8*6 Hexagon socket combination screw *6 SKU-02-004-00223

M3*8*10 Screw Dampener *10 SKU-02-001-02233

💡 What do we need in this section:

1. Reconnect and secure the nozzle connector, and gently

places the connector back into the Motor Housing Kit.

2. Connect the liquid tube to the Nozzle Inlet .

3. Assemble and fixes the Nozzle in the direction as shown

in the figure.

🛠Assemble:

CHECK :

@2020 XAG Australia All Rights Reserved