SHOCKS

Shocks, or shock absorbers, are

a part of the suspension that

allow the wheels to keep as

much contact with the running

surface as possible. Damping,

mounting position, spring

tension, and spring preload

are all characteristics that

determine how the shock

performs.

SShhoocckk sseettttiinnggss::

The T EVO2 features unique 4-step externally adjustable racing shocks that

do not require you to change pistons or change the oil to alter the damping.

Initially, the damping should be set separately for the front and the rear so

that the car quickly settles when dropped from approximately 5 cm (2"). For

our initial settings, if it bounces before settling, it is too stiff. If it slaps the

table, it is too soft.

•• SSoofftt ddaammppiinnggwill produce most grip (both front and rear) through chassis

roll, but this will also decrease the cornering speed.

•• HHaarrdd ddaammppiinnggwill make the car break traction more easil , but with less

chassis roll and higher cornering speed.

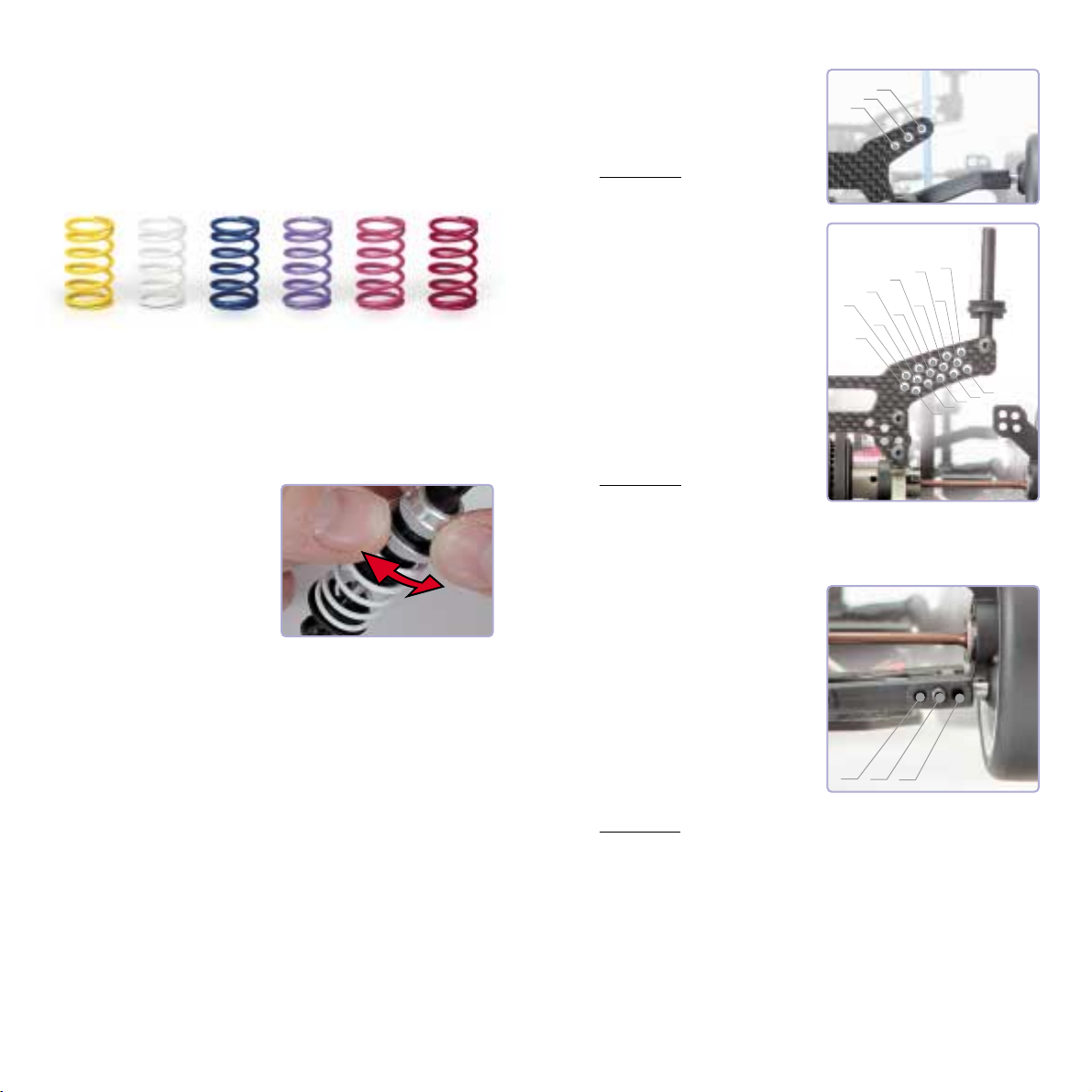

SSpprriinnggss::

The shock springs support the weight of the car. Different spring tensions

determine how much of the car's weight is transferred to the wheel relative to

the other shocks. The spring tension also influences the speed at which a

shock rebounds from compression.

Spring selection depends on the whether the track is fast or slow, or has

high or low traction.

••SSttiiffffeerr sspprriinnggss::Makes the car feel more responsive, more direct. The car will

react faster to driver input. Stiff springs are suited for tight, high-traction

tracks that aren't too bump . Usuall when ou stiffen the whole car, ou

lose a small amount of steering. Stiffer springs reduce chassis roll.

••SSoofftteerr sspprriinnggss::Better for bump and ver large and open tracks. The can

also make the car feel as if it has a little more traction in low-grip

conditions. Springs that are too soft make the car feel sluggish and slow.

Softer springs allow more chassis roll.

••SSttiiffffeerr ffrroonntt sspprriinnggss::The car will be more stable, but will have less front

traction and less steering. It will be harder to get the car to turn, the turn

radius will be bigger. The car will have a lot less steering exiting corners.

On ver high-grip tracks, if the track itself feels tack or stick , ver stiff

springs are preferred.

••SSoofftteerr ffrroonntt sspprriinnggss::The car will have more steering, especiall in the middle

and exit of the corner. Front springs that are too soft can make the car

oversteer.

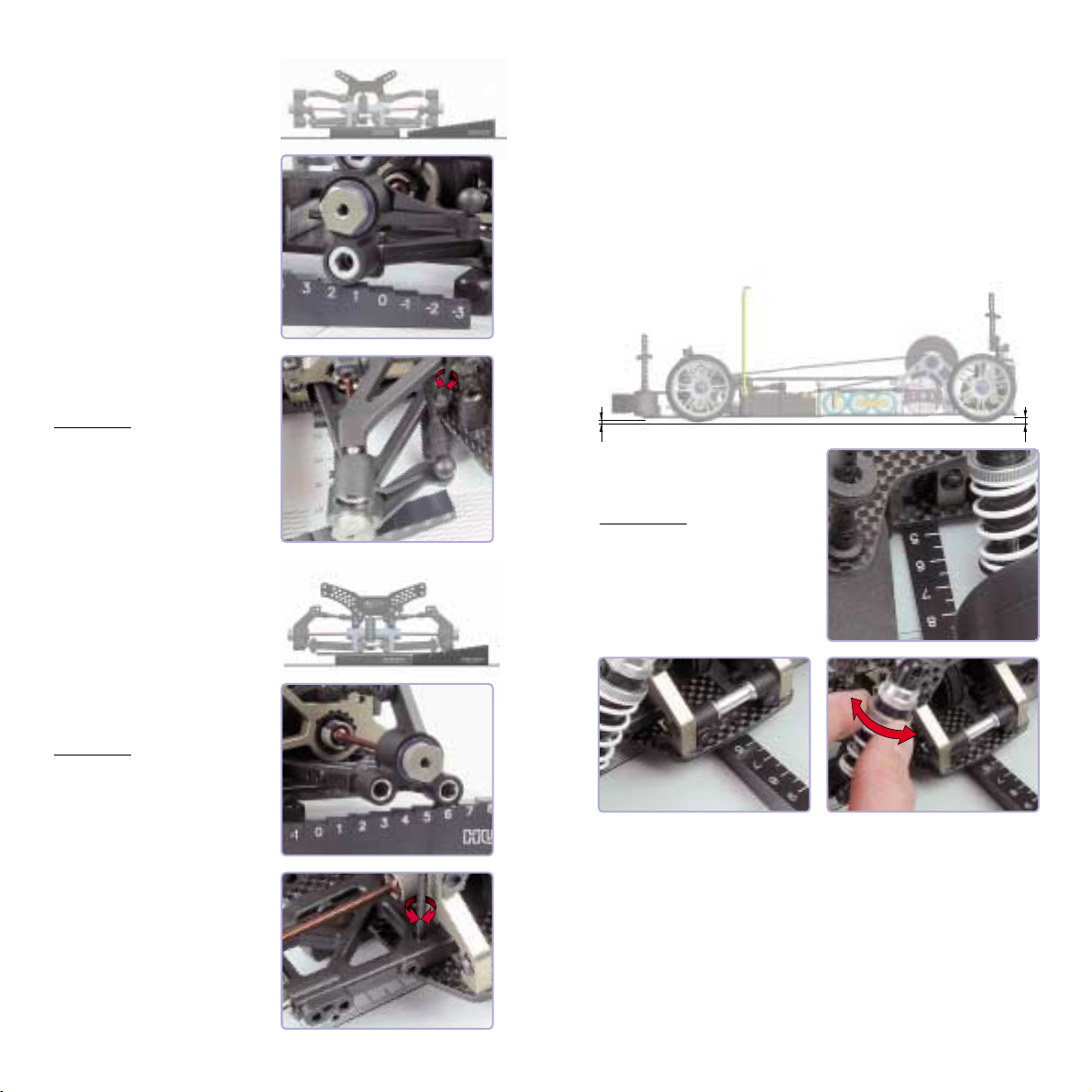

Final Adjustments

To let the front wheels freewheel, hold the locknut securely with pliers, then

rotate the spur gear backwards. The locknut will back away from the fixed

pulley and move towards the left bulkhead.

NOTE: Pull the fixed pulley away from the one-way pulley to let the front belt

move freely without binding.

22.. TTiigghhtteenneedd oonnee--wwaayy ppuulllleeyy

The pulley should be tightened under

slippery conditions, if you need to

lessen steering, or if heavy braking is

needed.

To tighten the one-way pulley, hold the

locknut securely with pliers, then rotate

the spur gear forwards. The locknut

will tighten the fixed pulley and move

towards the right bulkhead.

ONE-WAY FRONT DIFFERENTIAL (available option)

What is the difference between the one-way pulley

and the optional one-way diff?

The one-way pulley allows differential action under

acceleration. That means that when going through a

turn on throttle, if the inside wheel breaks traction, it

can still "unload" and prevent the outer wheel from

getting any power. The optional front one-way

differential (#30 5 00) gets around this problem by giving each wheel its

own independent one-way bearing. This way, the two wheels can rotate at

different rates, like with a regular differential, but on throttle, if one wheel

looses traction, the other one still gets power to pull the car through the turn.

Keep in mind that when using the one-way pulley with a loose setting or

when using the one-way differential, no drag brake should be used. Most

racers will also find it more convenient to set their radio to give less braking

action (use the throttle EPA setting); this will prevent the rear tires from

locking unexpectedly.

Use table below as a general guideline for the use of the one-way pulley and one-way differential.

TRACK SURFACE ONE-WAY PULLEY ONE-WAY FRONT

LOCKED LOOSENED DIFFERENTIAL

Low tra tion

Medium tra tion

(slow, tight orners)

High tra tion

(slow, tight orners)

High tra tion

(fast, sweeping orners)

✔

✔✔

✔✔

Final Adjustments

10

9