- 4 -

SAFETY PRECAUTIONS

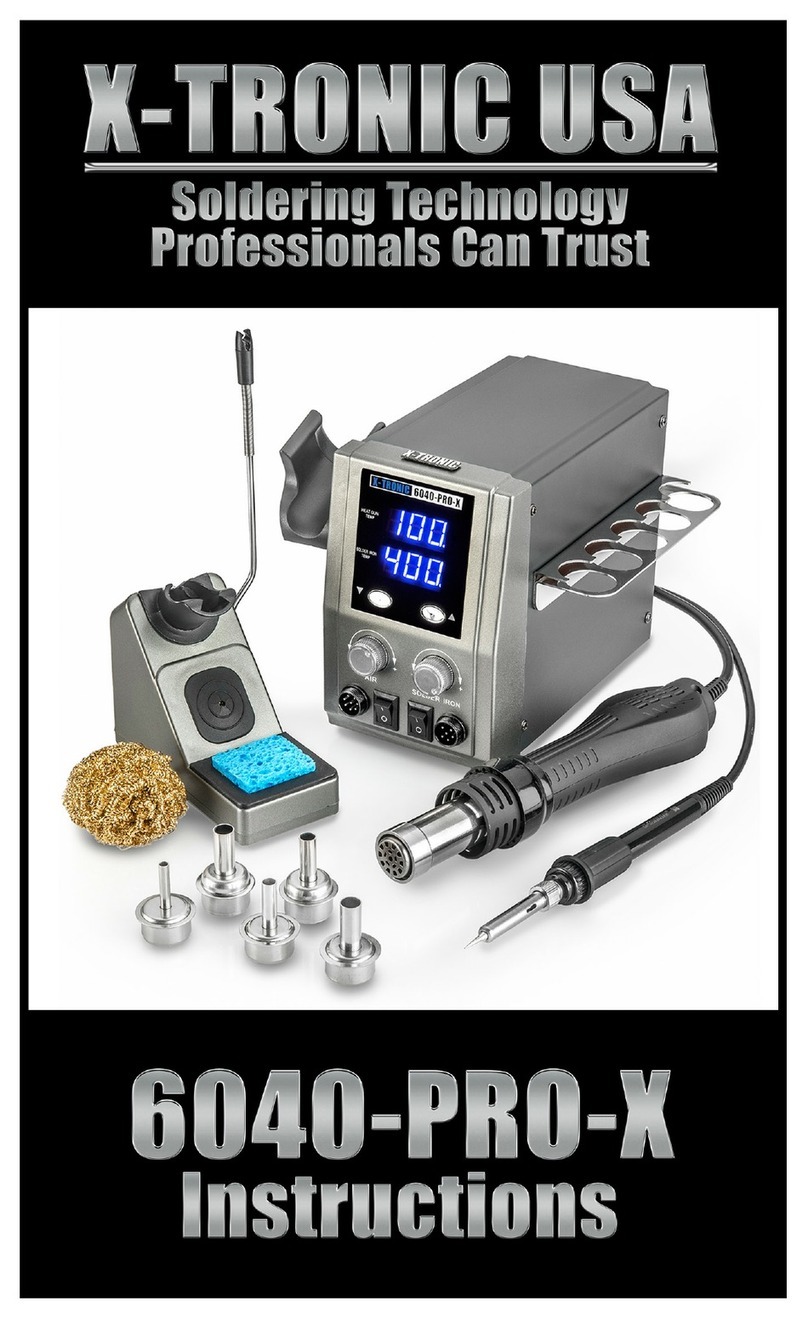

1. When initially powering on the unit and when powering down, the

hot air gun should ALWAYS be in the side holder. It should NEVER

be in the vertical position when the unit is initially turned on. If it is

used vertically with the appropriate air flow, it MUST be returned to

the side holder for cool down.

2. When using the hot air gun in the vertical holder the air flow MUST

be turned up to at least 4 or higher the entire time the hot air gun is

in this position. If the air flow is not sufficient the life of the heating

element will be greatly reduced.

CAUTION! IF #2 IS NOT FOLLOWED

The hot air gun will overheat and may cause the polymer on the front of

the hot air gun to melt and get red hot from the intense heat.

3. Never use the soldering iron or the hot air gun near any flammable

substance, material, or gas.

4. Never touch the metallic components of the soldering iron or the

hot air gun while they are in use. They are extremely hot and will

cause serious burns instantly. Allow the unit to properly cool to

room temperature before attempting to touch them.

5. Never point the hot air gun towards human skin. The air exiting the

hot air gun is VERY HOT and WILL cause serious burns.

6. Do not use pliers or any other tool to manipulate hot air nozzles.

7. Do NOT try to reform nozzle attachments into other shapes.

8. Never place anything flammable on or near IR Preheating Plate.

9. Never Touch the IR Preheating Plate or surrounding chassis while

in operation.

10. Ensure a minimum distance of 2mm while using the hot air gun in

the hands-free telescopic hot air gun holder.

11. Always keep the hot air gun moving, unless reflowing large chips.