SANITARY PUMPS

FEATURES

Body: Type 316 Stainless Steel

Impeller: Jabsco Neoprene Compound

Seal: Sanitary Carbon Face

Bearings: Ball Bearing

Shaft: Type 316 Stainless Steel

Ports: 2” Acme Threads, 2” Clamp

Weight: 34 lb (15,4 kg) approx.

Model 15170-Series

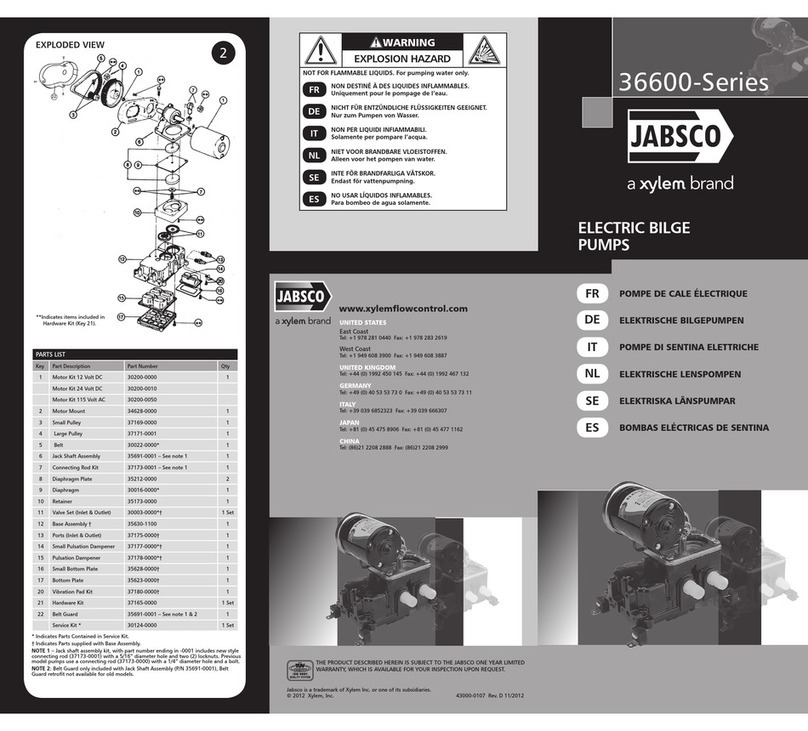

VARIATIONS

MODEL DESCRIPTION

15170-0005 2” Acme Thread Ports

15170-0015 2” Clamp Ports

Capacities and horsepower ratings are based on maximum head of

20 feet or 10 psi. Additional horsepower may be required when head

pressures exceed 10 psi. Farm tank outlet inside diameter must be

1-3/8” with 1-1/2” hose to obtain capacities to 65 GPM and 1-7/8” with

2” hose for capacities to 90 GPM.

Table shows approximate capacity, in U.S. gallon per minute, for new

pump with 20 feet of suction line. High starting torque motors are

required. Pump starting torque in dry condition (no fluid in pump

body) is 228 inch-pounds and in wet condition (fluid in pump body) is

168 inch-pounds. Impeller direction reversing torque in dry condition

is 336 inch-pounds and in wet condition is 228 inch-pounds. Appli-

cations requiring continual reversal of impeller are not recommended.

This product is specifically designed for farm pick-up milk tanker

trucks equipped with a remote drive. Jabsco pumps are also

available pedestal mounted with capacities to 100 GPM. Contact

factory for details.

1. INSTALLATION – Pump may be mounted in any position. The

rotation of the pump shaft determines the location of the pump’s

intake and discharge ports; refer to dimensional drawing. Pump is

normally assembled at factory for clockwise rotation, looking at end

cover. If counterclockwise rotation is desired, follow steps 1,2 & 3

of disassembly and steps 3, 4 & 5 of assembly instructions to

change direction of impeller blade deflection under cam. Before

use, rotate pump shaft in direction of operating rotation.

2. DRIVE – Belt or direct.

BELT: Proper belt tension will insure optimum performance,

bearing and belt life.

DIRECT: Clearance should be left between drive shaft and pump

shaft when installing coupling. Mount and align pump and drive

shaft before tightening set screw. Flexible coupling is

recommended. NOTE: Capacitor type motor is required.

SUCTION &

CAPACITY DISCHARGE PUMP HP

GPM LINE SIZE SPEED REQ.

65 1-1/2” ID 1100 1-1/2

90 2” ID 1525 2

PERFORMANCE CHART

3. SELF-PRIMING – Vertical lifts to 10 feet when dry. INTAKE LINES

MUST BE AIRTIGHT to prevent product foaming and assure

self-priming. Use noncollapsible hose.

4. RUNNING DRY – The impeller is lubricated by the product being

pumped. CAUTION: DO NOT RUN DR Y for more than 30 seconds.

Lack of liquid will damage the impeller.

5. NOTICE – If pumping light fraction petroleum derivatives, solvents,

thinners, highly concentrated or organic acids, consult Jabsco

Chemical Resistance Table (which is available upon request from

Jabsco) for proper body materials and impeller compounds. If

corrosivefluidsarehandled,pumplifewillbeprolongedifpumpis

flushed with a neutralizing solution after each use or each work day.

6. PRESSURES – Consult performance chart. Contact factory for

higher head applications.

7. TEMPERATURES–Standard impeller 40° to 150° F (4° to 65° C).

Contact factory for impeller recommendation on applications outside

this range. Other impeller compounds are available which may be

utilized for certain applications at higher or lower temperatures.

MODEL 15170-SERIES