●Q & A…………………………..………………………..….…P. 16-17

INTRODUCTION

:【WARNING 】and【CAUTION 】 【ELECTRICAL SHCOK 】

Warning and caution are positioned at critical points in the manual to

draw the user’s attention to significant safety concerns. Be sure to comply

with the following warnings and cautions for your safety.

11. Ensure the voltage rating of the unit and your power supply are identical prior to

use.

22. Check carefully of any damage during transportation.

33. Put the products on a safe and stable working table. Table surface should be

consisted of fire and heat resistant material due to the unit can reach very high temperature

and potentially dangerous.

44. During the operation, the heater is extremely hot, and will cause serious burns if

contacted exposed skin. Use gloves and/or any heat resistant tools to pick up the PCB

assembly to eliminate the possibility of burns.

55. Do not use the product near combustible gases or flammable materials.

66. Turn the power switch OFF and allow the heater to cool before checking or

replacing heater and other parts, or prior to storing the unit.

77. Keep the appliance clean especially the quartz heater. This may be used with a

damp cloth using small amount of liquid detergent. Never submerse the unit in liquid or

allow any liquid to enter the station. Never use any solvent to clean the case.

88. Quartz heater is fragile, be slightly moving the station if necessary.

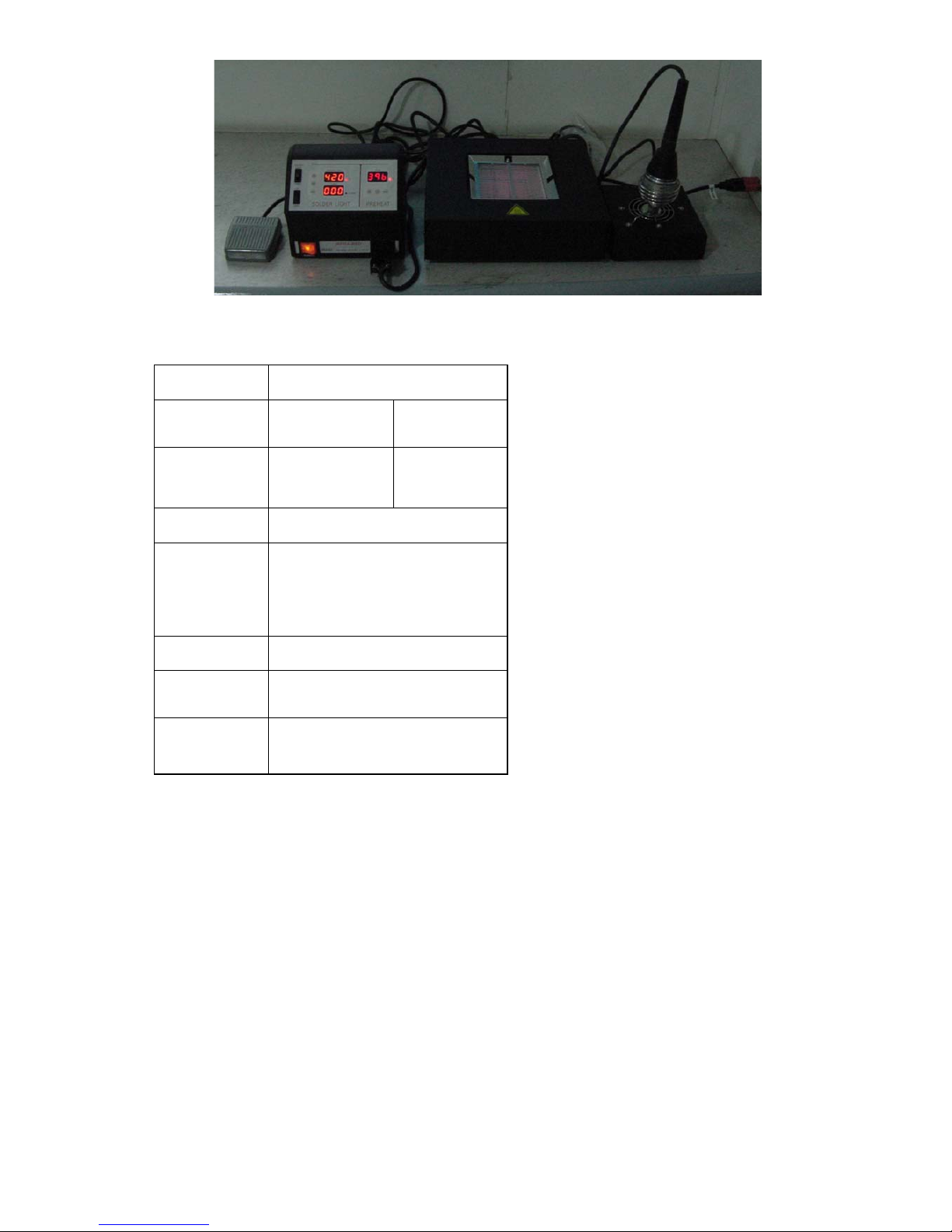

99. This unit is designed for SMD rework, BGA re-balling and pre-heating PCB

assembly and should not be used for any other purpose without first consulting the

manufacturer or its authorized agent.

10 10. Keep the unit out of the reach of children. Young Children should be supervised

to ensure that they do not play with the appliance.

To prevent electrical shock, be sure to take the following precautions:

1Make sure the unit is grounded. Always connect power to a grounded receptacle.

2Do not pressure the AC power cord. Be sure the work area is well ventilated.

3Do not bump, hit, pour water/liquids or otherwise subject the heating surface to

physical shock. This may damage the quartz heater.

4To isolate the equipment from the mains before commencing repairs or making any

maintenance to avoid electric shock. This may result in Death or serious injury.

5Do not expose the unit to moisture nor use the unit with wet hands.

6Turn the power switch off and remove the AC power cord by pulling the plug (not

the cable) when the unit will remain unused for a longer period of time.

7Do not modify the unit.

Warnings

ٛThis system is designed to be used for soldering/desoldering SMDs and should