7

5. Do not use fluxes which contain chloride or acid. Use only rosin or resin activated

fluxes.

6. If an oxide film forms, it can be removed by careful buffing with 600-800 grit

emery cloth, isopropyl alcohol or equivalent and then the tinned areas with

rosin-core solder after the resin-core has melted.

NEW TIPS

Applying the following steps give the tip optimum life.

1. Set both temperature to min. then turn the main power switch to the “ON”

position.

2. Set soldering tip temperature to 250℃(500℉approx.) and desoldering tip

temperature to min. Coat the tinned surfaces with rosin-core solder after reaching

250℃.

3. Set to the desired temperature about 3 minutes after being warmed that the station

will be ready for sue once it reaches preset temperature.

IMPORTANT: Remove and clean the tip daily. If a new tip is installed, remove any

loose build up ion the tip and barrel assembly, otherwise the tip may fuse to the

heating element or retaining barrel.

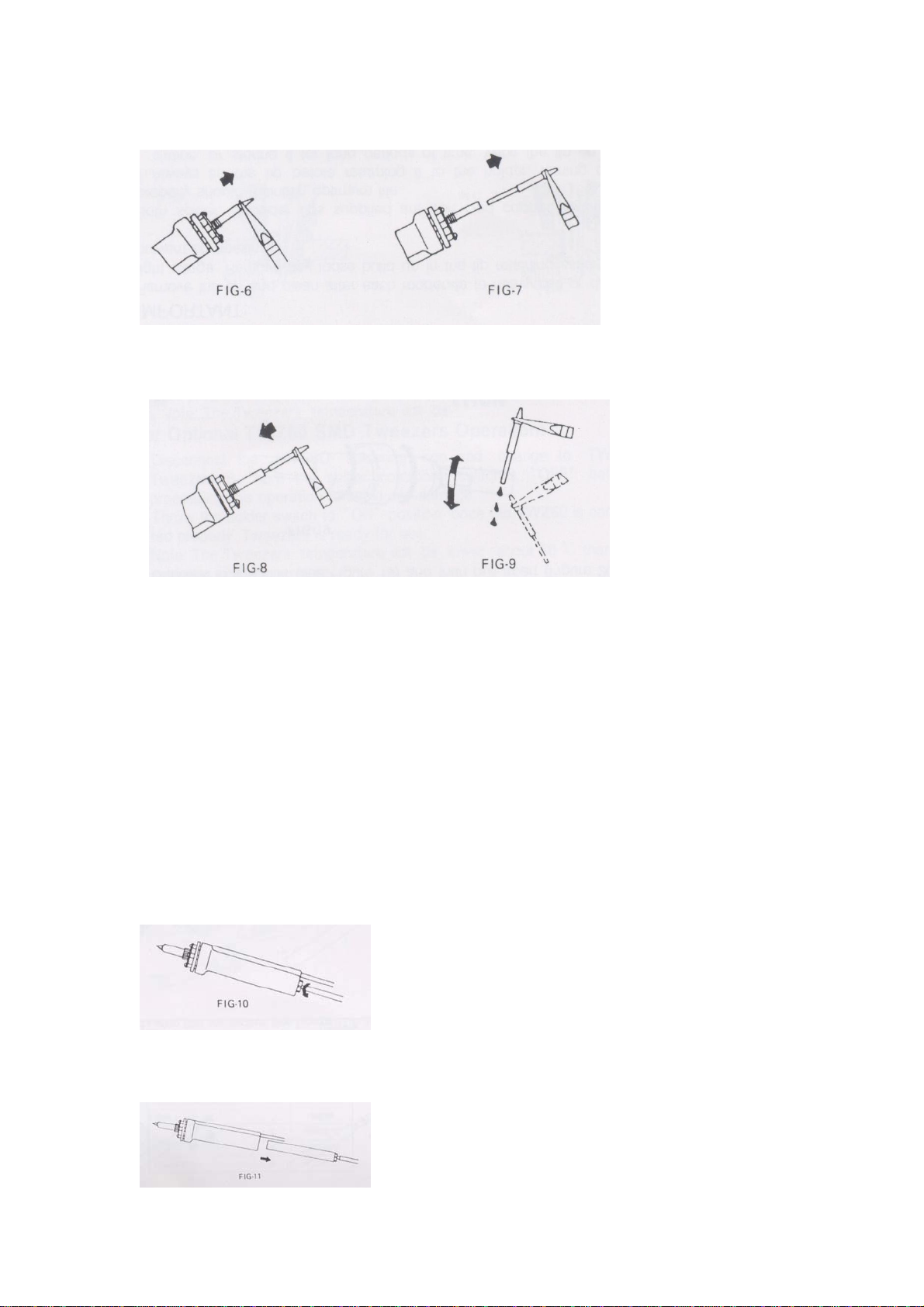

METHOD TO CHECK FOR LOSS OF SUCTION

The following procedures should be used on LF-8000 to check whether loss of

suction is due to the tip, solder collector, tube or in-line filter.

CAUTION: THE DESOLDER SWITCH MUST BE “OFF” AND ALLOW THE

IRON TO COLL BEFORE ATTEMPTING THE FOLLOWING PROCEDURES:

1. Disconnect vacuum tube form the fitting on the front panel, place finger over the

hole of the fitting, depress vacuum switch and you should have a strong vacuum.

If not, send back to your nearest service center for pump repair.

2. Disconnect the inline filter from the iron assembly, depress vacuum switch,

replace filling of the in-line filter if there is little vacuum pressure or the filters are

discolored.

3. Remove solder collector from desolder iron assembly, place finger over the hole

of the collector, depress vacuum switch. There is little suction clean or replace the

collector tube.

4. Depress vacuum witch, clean the tip tube with spring wire provided if there is no

suction per the “Procedure for Cleaning Clogged Tip” section below.