Contents

1. Safety Precautions ................................................................. 1

Explanation.......................................................................... 1

Table of Illustrated Symbols ............................................................ 2

Warning・Caution .................................................................... 3

2. Before Using ...................................................................... 6

Installation precautions ................................................................ 6

Preparation before operation .......................................................... 10

3. Description and Function of Each Part.............................................. 16

Main unit (front·top·back) ............................................................. 16

Main unit (internal structure)........................................................... 17

Operation panel ..................................................................... 18

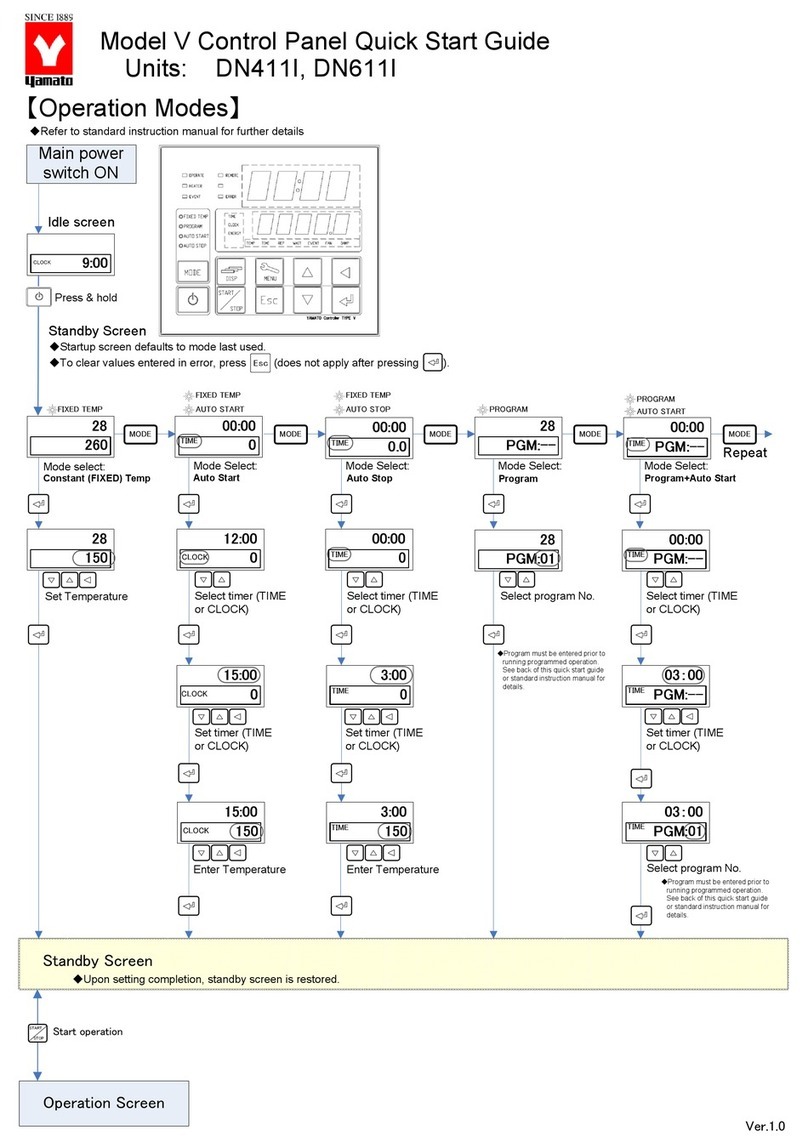

4. Operation Method................................................................. 19

Choose operation mode .............................................................. 19

Function list......................................................................... 20

Help function........................................................................ 22

User Set Function ................................................................... 23

Operation course (liquefy & retain temp.)................................................ 25

Operation course (sterilize & retain temp.)............................................... 34

Operation course (instrument sterilize).................................................. 43

Operation course (fluid sterilize) ....................................................... 49

Operation course (instrument dry)...................................................... 55

Operation course (sterilize & dry) ...................................................... 61

Shortcut function (preheating) ......................................................... 69

Shortcut function (memory) ........................................................... 72

Shortcut function (schedule)........................................................... 76

Shortcut function (initial setting value) .................................................. 81

Shortcut function (optional connector) .................................................. 82

External Output Terminal (optional)..................................................... 83

5. Handling Precautions ............................................................. 85

6. Maintenance Method .............................................................. 88

Daily Inspection and Maintenance...................................................... 88

7. Long storage and disposal......................................................... 89

When not using this unit for long term / When disposing................................... 89

Notes about disposal................................................................. 89

8. In the Event of Failure ............................................................. 90

Safety Device and Error Code ......................................................... 90

Trouble Shooting .................................................................... 92

9. After-sales Service and Warranty ................................................... 93

When need repair ................................................................... 93

10. Specification .................................................................... 94

11. Wiring Diagram .................................................................. 96

12. Piping Diagram .................................................................. 98

13. Replacement Parts Table ......................................................... 99

14. List of Dangerous Substances.................................................... 101