YASKAWA GA500 series User manual

Other YASKAWA DC Drive manuals

YASKAWA

YASKAWA CIPR-GA50UB001AJ Series Instruction Manual

YASKAWA

YASKAWA 1000-Series User manual

YASKAWA

YASKAWA 1000 Series User manual

YASKAWA

YASKAWA CDBR Series User manual

YASKAWA

YASKAWA Varispeed f7 User manual

YASKAWA

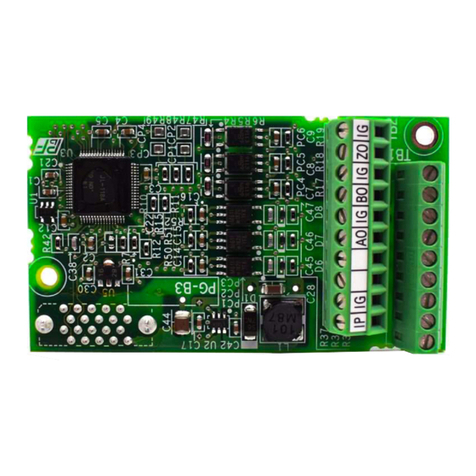

YASKAWA JOHB-SMP3 User manual

YASKAWA

YASKAWA 1000 Series User manual

YASKAWA

YASKAWA SI-EN3/V User manual

YASKAWA

YASKAWA CR700 User manual

YASKAWA

YASKAWA GA700 User manual

YASKAWA

YASKAWA CIMR-AC4A0103TAA User manual

YASKAWA

YASKAWA J1000 CIMR-JC series User manual

YASKAWA

YASKAWA 1000 Series User manual

YASKAWA

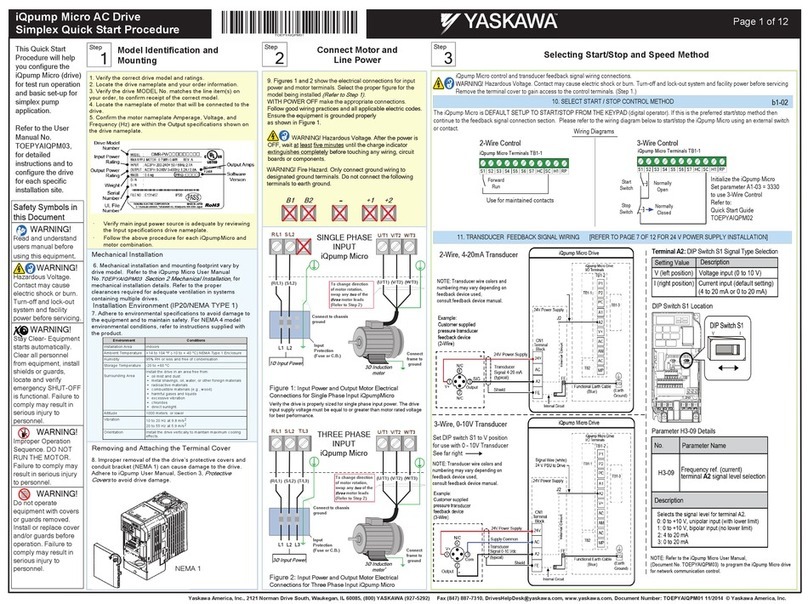

YASKAWA iQpump Micro User manual

YASKAWA

YASKAWA LA500 Owner's manual

YASKAWA

YASKAWA ZPSA-600-EH1-FR Series User manual

YASKAWA

YASKAWA JOHB-SMP3 User manual

YASKAWA

YASKAWA 1000 Series User manual

YASKAWA

YASKAWA VS MINI J7 Guide

YASKAWA

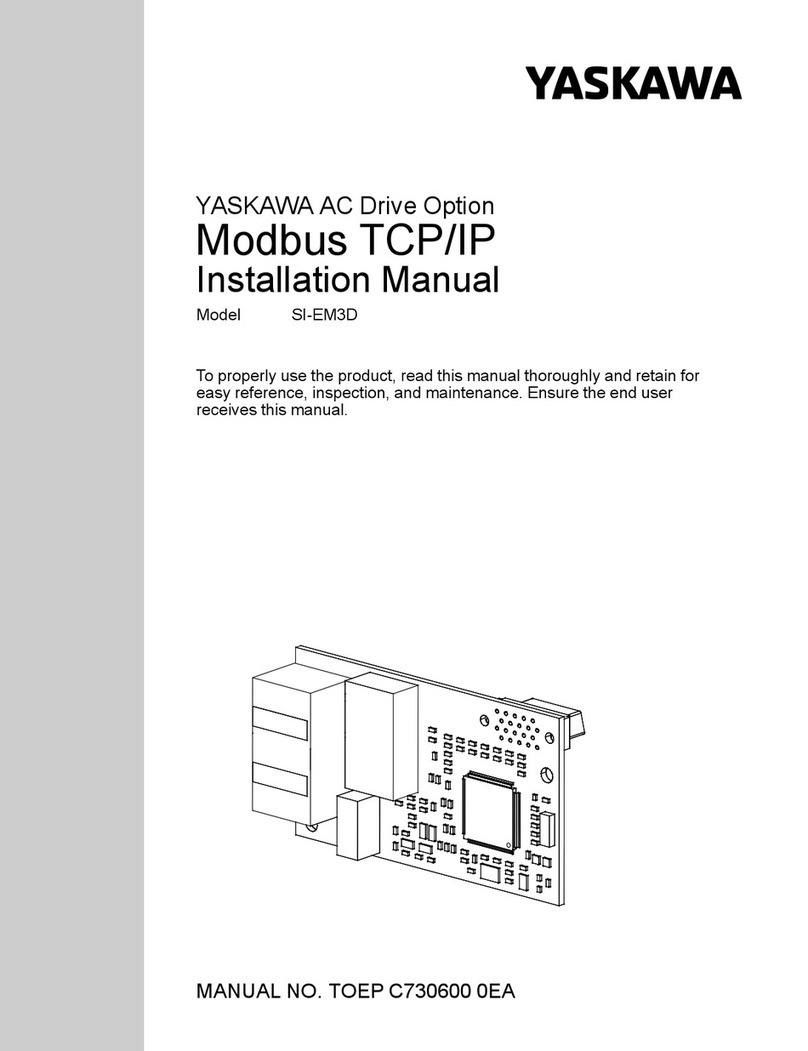

YASKAWA SI-EM3D User manual