to what you do. Do not work if you are tired or under effects of medicines or

alcohol. Even a moment’s inattention during work may lead to serious injuries. Always

use individual means of protection. Always wear goggles. Using individual means

of protection, such as dust-masks, protective shoes, helmets and hearing protections

permits to reduce the risk of serious injuries. Avoid accidental activation of the tool.

Make sure the switch is in the OFF position, before you connect the tool to the

mains. Holding the tool with a finger on the switch or connecting an electric tool when

the switch is in the ON position may lead to serious injuries. Before you turn an elec-

tric tool on remove all the spanners and other tools, which have been used for

adjustments. A spanner left on rotating elements of the tool may lead to serious inju-

ries. Keep your balance. Maintain an appropriate position. It will permit to control

the electric tool in case of unpredicted situations during its operation. Use protec-

tive clothes. Do not wear loose clothes or jewellery. Keep your hair, clothes and

gloves away from moving elements of the electric tool. Loose clothes, jewellery or

long hair may get caught on moving elements of the tool. Use dust extractors or dust

containers, if the tool is equipped with any. Make sure they are properly con-

nected. Using of dust extractors permits to reduce the risk of serious injuries.

Operation of the electric tool

Do not overload the electric tool. Use a proper tool for the given purpose. A cor-

rect selection of the tool for the given work will result in a more efficient and safer

work. Do not use the electric tool if the switch is not functioning properly. A tool

which may not be controlled by means of a switch is dangerous and must be repaired.

Disconnect the plug from the mains socket before any adjustment, replacement

of accessories or storage of the tool. It will permit to avoid accidental activation of the

electric tool. Store the tool away from children. Do not allow untrained persons to

operate the tool. An electric tool may be dangerous in hands of an untrained person.

Make sure the tool is properly maintained. Check the tool in order to detects

any unfitting or loose moving elements. Check whether the elements of the tool

are not damaged. In case any damaged elements of the tool are detected, they

must be repaired before the electric tool is operated. Many accidents are caused

by improper maintenance of tools. Cutting tools must be sharp and clean. Properly

maintained cutting tools are easier to control during work. Use electric tools and ac-

cessories in accordance with the aforementioned instructions. Use the tool in ac-

cordance with its purpose, taking into account the kind and conditions of work.

Should the tool be used for other applications than the ones it has been designed for,

the risk of a dangerous situation increases.

Repairs

The tool may be repaired only by authorised service centres, which must use

solely original spare parts. It will guarantee a proper level of safety of operation of

the electric tool.

SAFETY USE INSTRUCTIONS

The soldering tool may be connected solely to the 230V/50Hz mains. In order to avoid

fire and burns, always use special non-flammable bases under the soldering tool. Once

the soldering tool has been heated, it must be held solely by the handle. Touching of

the soldering tip or other metal elements of a hot soldering tool may cause burns. Do

not permit any contact of the power supply cable with hot metal elements since this

might result in an electric shock. If the cable is damaged, the soldering tool must be

disconnected from the power supply mains. It is prohibited to work with a soldering

tool with a damaged power supply cable. A damaged cable must by replaced by an

authorised service centre. Do not repair damaged electric cables of the tool. After

work, the tool must be placed on the base to cool. This is the only acceptable manner of

cooling the tool. Do not cool the soldering tool placing it in water, since this may cause

an electric shock. The soldering tip of the soldering tool must be replaced solely when

the power supply if off. The plug of the power supply cable must be disconnected from

the mains. Before you proceed to replace the soldering tip, make sure the soldering

tool has cooled. The soldering tip must be inserted until you feel resistance. Fasten

the soldering tip in the fixture securely. Do not heat the soldering tool if a soldering tip

is not installed. A lack of a soldering tip during heating may cause a premature wear of

the heating element of the soldering tool. Before you proceed to heating, make sure

the soldering tip is securely fastened to the soldering tool. Maintain the heating ele-

ment and the soldering tip of the soldering tool clean. It is prohibited to touch electric

cables insulation with a hot soldering tip. It is prohibited to use the soldering tool in high

humidity conditions and in an explosive atmosphere containing gases and explosives

or caustic dusts. Do not solder live element!

PREPARATION FOR WORK AND USING OF THE TOOL

Before work is commenced, make sure the body the cable with a plug and the exten-

sion cords are not damaged. If necessary, the tool must be cleaned and the ventilating

holes cleared. If any damage is detected, it is prohibited to continue working! Note!

All the actions related to replacement or cleaning elements of the soldering tool must

be realised when the power supply of the tool is off, so before you proceed to these

actions: Disconnect the plug of the power supply cable of the tool from the mains

socket! Soldering must be realised by an adult acquainted with the industrial safety

regulations related to soldering. Before the tool is used, make sure the parameters of

the power supply mains correspond to the data presented in the rating plate. Before

soldering, clean thoroughly the metal elements to be soldered as well as the soldering

tip of the soldering tool. In case the soldering tip is burnt, replace it with a new one.

Before soldering, clean the surface to be soldered of any foreign matter, particularly

grease. Do not ever grind the soldering tip with abrasive paper, since it would damage

the soldering tip coating.

Replacement of soldering tip

A used, narrow or dirty soldering tip must be replaced.

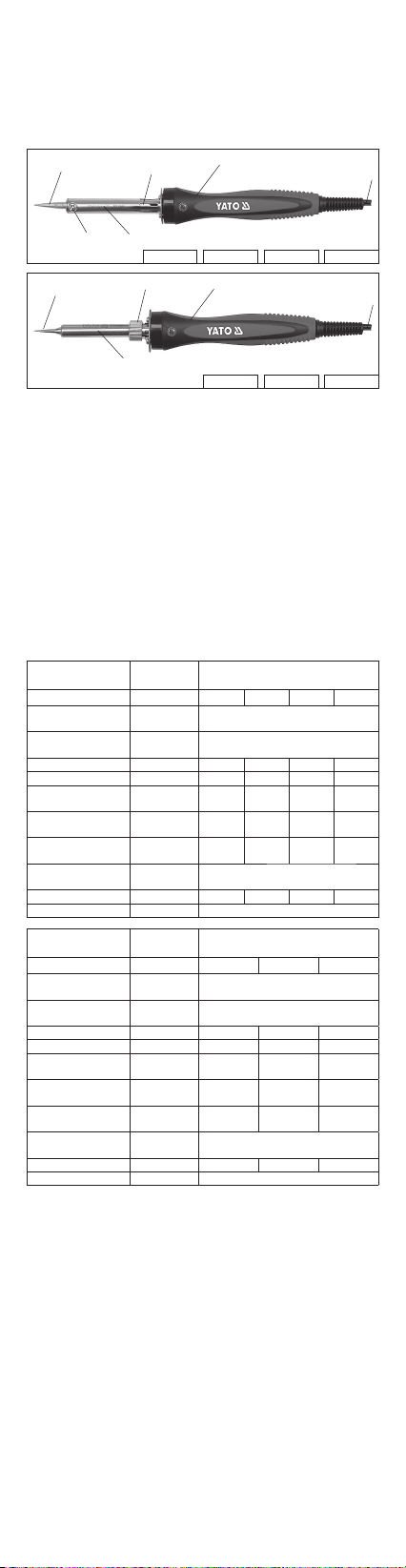

For the soldering tool YT-8250, YT-8251, YT-8252, YT-8253 loosen the screws at the

soldering tip, and then remove it and replace with a new one. Make sure the soldering

tip touches the heating element, and then tighten both screws.

For the soldering tool YT-8254, YT-8255, YT-8256 loosen the nut at the handle of the

soldering tool, and then remove the nut along with the protecting sleeve. Replace the

soldering tip, install the protecting sleeve and tighten the nut.

Replacement of the heating element

Replacement of the heating element is complex and it requires adequate knowledge

and authorisation. The heating element must be replaced by qualifies personnel in an

authorised service centre.

Guidelines and recommendations regarding soldering

Select a soldering tool, whose power corresponds to the kind of work to be realised.

Power 15 - 30 W: soldering of elements on integrated circuit boards, soldering of small

electronic elements. Power 40 - 60 W: Soldering of electronic and electric elements

(e.g. switches and contacts). Make sure the soldering tip is clean and properly fixed

in the soldering tool. Place the soldering tool on the base, and then connect it to the

mains. Wait until the soldering tip has reached a required temperature. Commence

soldering using flux and filler metal (soldering tin). The soldering tip must only touch the

places that are meant to be soldered. The filler metal should flow off the soldering tip to

the weld, when it reaches an adequate temperature. Once the task has been finished

and when the tool is not operated, it must be placed on the base.

MAINTENANCE AND INSPECTIONS

NOTE! Before any adjustment, technical service or maintenance, the plug of the tool

must be removed from the mains socket. Once work has been concluded check the

technical conditions of the electric tool by means of visual inspection and evaluation of

the body and handle, the electric cord with the plug, operation of the switch, clearance

of the ventilating holes, sparking of the brushes, the level of noise emitted by the bear-

ings and gears, start and smoothness of operation. Within the guarantee period, the

user must not dismantle the electric tool or replace any subassemblies or components,

since it will make the guarantee void. Any irregularities observed during inspection or

operation of the tool indicate it must be repaired by a service centre. Once work has

concluded, the body, ventilating holes, switches, additional handle and protections

must be cleaned, for example with an air jet (whose pressure must not exceed 0.3

MPa), brush or a dry cloth, without any chemicals or cleaning liquids. The tool and the

handles must be cleaned with a dry, clean cloth.