3

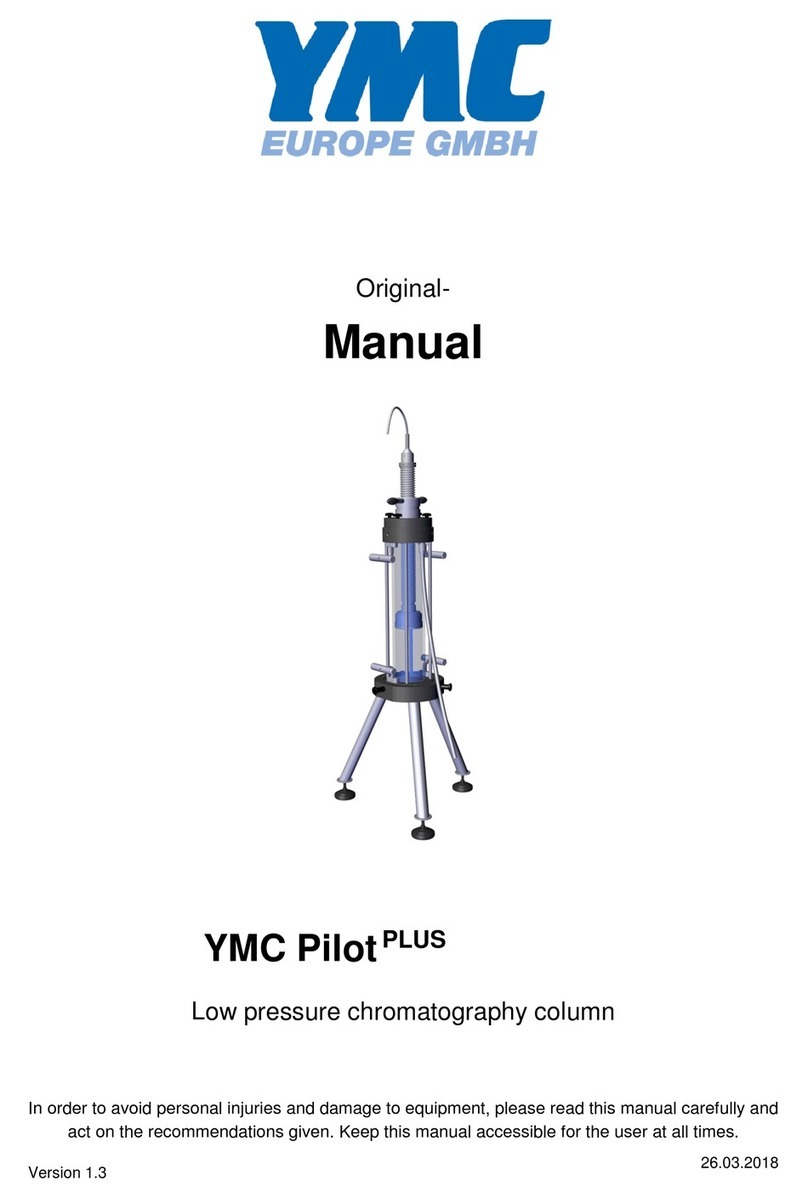

Low pressure chromatography column - Pilot series

Contents

1. Safety............................................................................................................... 5

1.1. Explanation of warning messages............................................................ 5

1.2. Layout of instructions ............................................................................... 6

1.3. Fields of applications................................................................................ 6

1.4. Intended use............................................................................................. 7

1.5. Personnel requirements............................................................................ 7

1.6. Personal protective equipment ................................................................ 7

2. Delivery............................................................................................................. 8

2.1. Delivery contents...................................................................................... 8

2.2. Delivery inspection ................................................................................. 10

3. Starting operations ...................................................................................... 11

3.1. Safety instructions for use...................................................................... 11

3.2. Column construction .............................................................................. 12

3.3. Specifications ......................................................................................... 14

3.4. Chemical resistance ............................................................................... 15

3.5. General operations ................................................................................. 17

3.5.1. Tightening and loosening of the O-ring........................................ 17

3.5.2. Adjusting the stamp height........................................................... 17

3.5.3. Connecting the tubing.................................................................. 17

3.6. Dismantling............................................................................................. 18

3.6.1 Dismantling of the column............................................................. 18

3.6.2 Dismantling of the glass body ....................................................... 19

3.6.3 Dismantling of the plunger ............................................................ 20

3.6.4 Removing of the frit ....................................................................... 21

3.6.5 Dismantling of the fixed stamp...................................................... 21

3.7. Cleaning.................................................................................................. 22

3.8. Assembling............................................................................................. 23

3.8.1. Assembling the frit........................................................................ 23

3.8.2. Assembling the plunger................................................................ 23

3.8.3. Assembling the glass body .......................................................... 24

3.8.4. Assembling the column ................................................................ 26

3.9. Pressure test........................................................................................... 27

3.10. Packing adapter ..................................................................................... 29

Contents