Inficon TPG300 User manual

Operating Manual

IG9970BEN (2017-04)

1

Total Pressure Gauge Controller

TPG300

2

IG9970BEN (2017-04) TPG300.om

In all communications with INFICON, please specify the information on the product

nameplate. For convenient reference copy that information into the space provided

below.

This document applies to products with part number

IO546900.

The part number (PN) can be taken from the product nameplate.

This document is based on firmware 302-654

If your unit does not work as described in this document, please check that it is

equipped with the above firmware version (→35).

We reserve the right to make technical changes without prior notice.

All dimensions in mm.

Depending on the options chosen, the TPG300 can measure total pressure from

atmosphere to 10

-11

mbar. It can trigger a number of pressure-dependent functions

to control and monitor vacuum devices and processes. The instructions contained

in this document must be strictly followed.

Product Identification

Validity

Intended Use

IG9970BEN (2017-04) TPG300.om

3

Contents

Product Identification 2

Validity 2

Intended Use 2

Contents 3

1

Safety 5

1.1

Symbols Used 5

1.2

Personnel Qualifications 5

1.3

General Safety Instructions 5

1.4

Liability and Warranty 6

1.5

Further Symbols 6

2

System Overview 7

2.1

Basic Unit 7

2.2

Measurement Plug-In Boards 7

2.3

Interface and Relay Plug-In Boards 7

3

Technical Data 8

4

Installation 10

4.1

Installation 10

4.1.1

Rack Installation 10

4.1.2

Installation in a Control Panel 11

4.1.3

Use as Desk-Top Unit 12

4.2

Mains Power Connection 14

4.3

Installing / Removing plug-in boards 15

4.4

Connecting plug-in boards 15

5

Operation 16

5.1

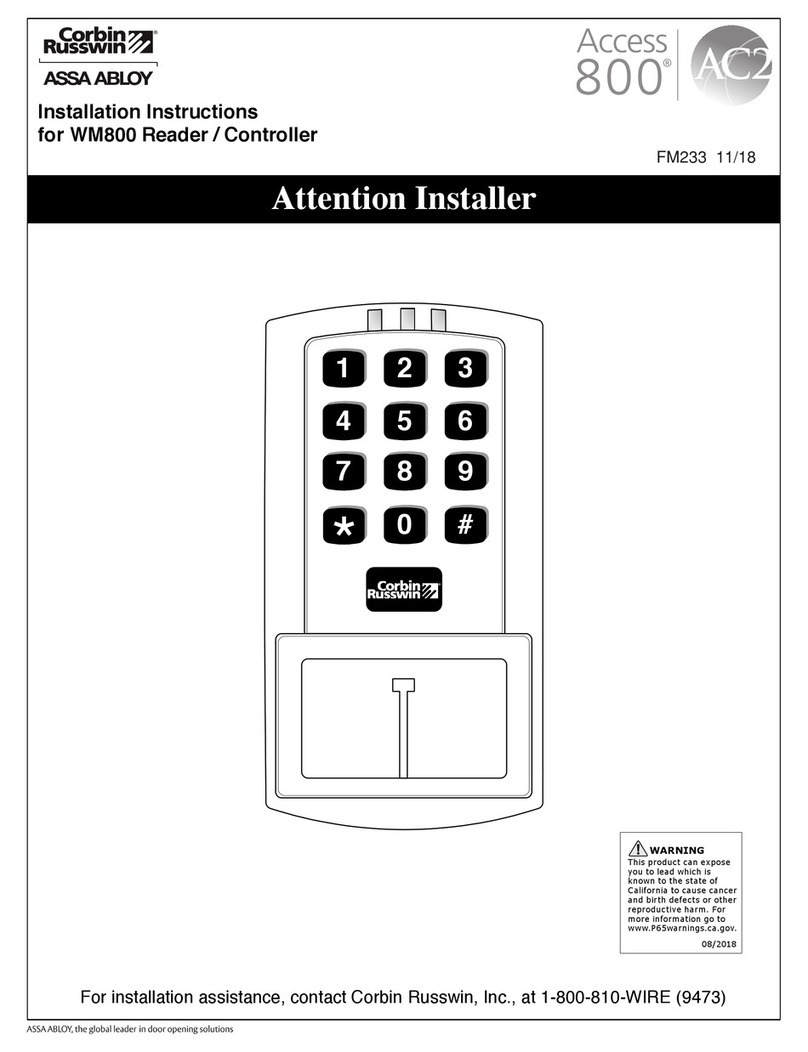

Front panel 16

5.2

Switching TPG300 On and Off 16

5.3

Measuring with the TPG300 17

5.4

Operating Modes 17

5.5

Operating Mode »sensor« 19

5.5.1

Key Entries 19

5.5.2

Switching the Measuring Circuit On / Off 20

5.5.3

Measurement Range Violation 20

5.5.4

Automatic Measuring Circuit Switchover 21

5.5.5

Self-Monitoring 21

5.5.6

Plug-In Board Identification 21

5.6

»set point« Mode 22

5.6.1

Key Entries 23

5.6.2

Parameter 24

5.7

»set up« Mode 24

5.7.1

Key Entries, Overview 25

5.7.2

»Switching Functions« Group 26

5.7.3

»PE Measurement Underrange Control« Group 29

5.7.4

»Measurement Unit« Group 29

5.7.5

»Filter« Group 30

5.7.6

»Interface« Group 32

5.7.7

»Parameter Storage« Group 33

5.7.8

»Test Programs« Group 35

6

Maintenance 38

7

Troubleshooting 39

7.1

Error Messages 39

7.2

Contact Setting of the Relays in the Event of a Fault 39

7.3

Installation Problems 40

7.4

Operating and Calibration Problems 41

8

Profibus Interface 42

9

Accessories 42

10

Storage 42

11

Disposal 43

4

IG9970BEN (2017-04) TPG300.om

Appendix 44

A:

Conversion Tables 44

B:

Default Parameters 45

C:

Program Examples 46

D:

Literature 47

EU Declaration of Conformity 48

For cross-references within this document, the symbol (→XY) is used; for cross-

references to further documents listed under ‘Literature’, use is made of the symbol

(→[Z]).

IG9970BEN (2017-04) TPG300.om

5

1 Safety

DANGER

Information on preventing any kind of physical injury.

WARNING

Information on preventing extensive equipment and environmental damage.

Caution

Information on correct handling or use. Disregard can lead to malfunctions or

minor equipment damage.

Skilled personnel

All work described in this document may only be carried out by persons who

have suitable technical training and the necessary experience or who have been

instructed by the end-user of the product.

Adhere to the applicable regulations and take the necessary precautions for all

work you are going to do and consider the safety instructions in this document.

DANGER

DANGER: mains voltage

Contact with live parts is extremely hazardous when any objects are

introduced or any liquids penetrate into the unit.

Make sure no objects enter through the louvers and no liquids pene-

trate into the equipment.

Communicate the safety instructions to all other users.

1.1 Symbols Used

1.2 Personnel Qualifications

1.3 General Safety

Instructions

6

IG9970BEN (2017-04) TPG300.om

INFICON assumes no liability and the warranty becomes null and void if the end-

user or third parties

•disregard the information in this document

•use the product in a non-conforming manner

•make any kind of interventions (modifications, alterations etc.) on the product

•use the product with accessories, options and add-ons not listed in the corres-

ponding product documentation.

… please contact your local INFICON service center.

Important Notice

Note

Special information on cost-effective use.

< … > Labeling

« … » Display, response

» … « Operating mode, effect

Waiting time, reaction time, duration of test

→See document …

→See page …

1.4 Liability and Warranty

1.5 Further Symbols

IG9970BEN (2017-04) TPG300.om

7

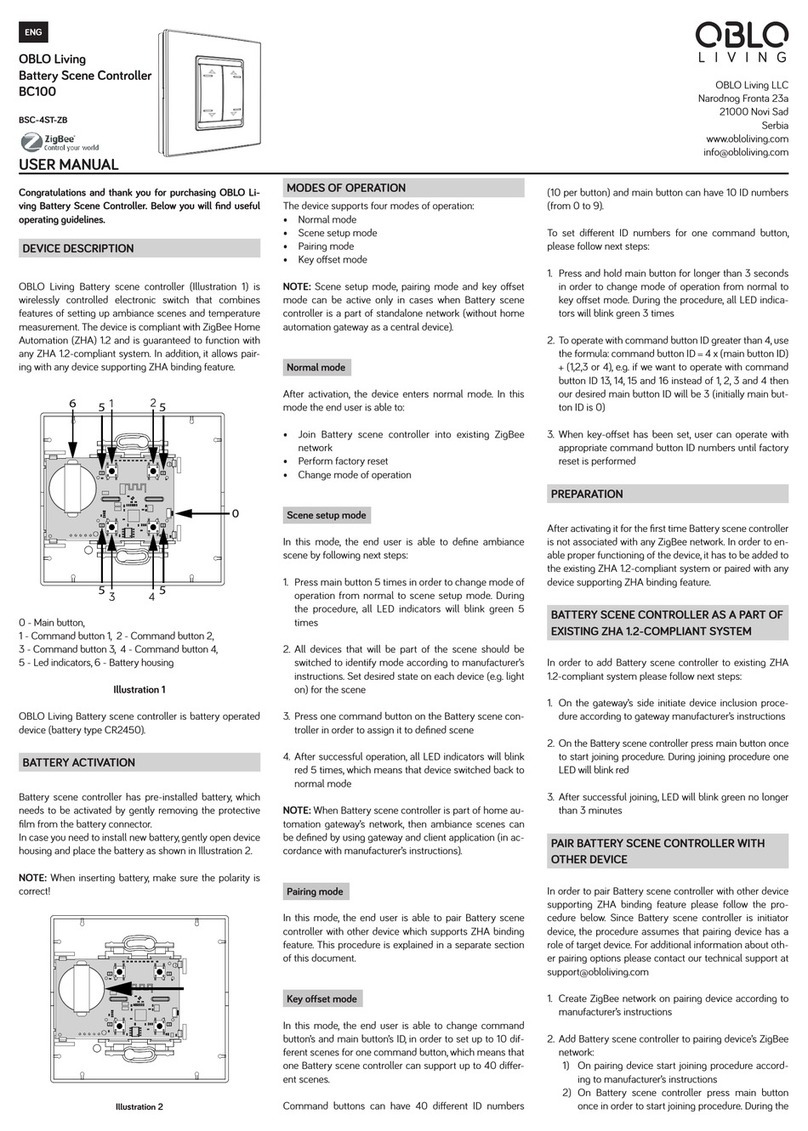

2 System Overview

TPG300, Technical Data →8.

A list of all plug-in boards suited for the TPG300 can be found on 8.

For detailed information on the plug-in boards →[1].

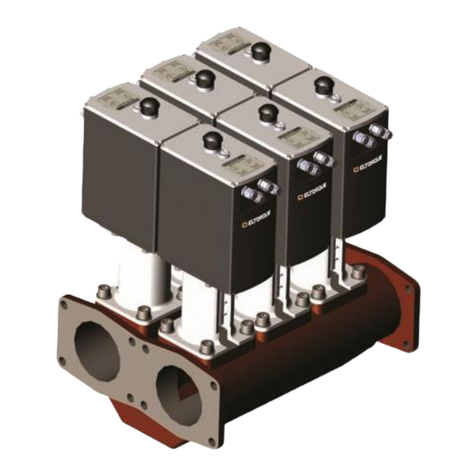

Two slots (A and B) at the back of the TPG300 can accommodate up to two

measurement boards.

Pirani / cold cathode combined

Measurement plug-in board:

CP300C9

Compatible gauges:

TPR018

IKR085

An interface and relay board can be plugged into slot C.

Profibus-DP

Interface

and Relays

IF300P

A B C

Interface and relay board

Power supply

Measurement

boards

A B C Power supply

Measurement

boards

Interface and relay board

2.1 Basic Unit

2.2 Measurement

Plug-In Boards

2.3 Interface and Relay

Plug-In Boards

8

IG9970BEN (2017-04) TPG300.om

3 Technical Data

Voltage 90 … 264 VAC ±10%

Frequency 47 … 63 Hz

Power consumption <55 VA

Overvoltage catagory II

Degrees class 1

Connection European appliance connector IEC 320 C14

Fuses none

Admissible temperature

Storage

Operation

Rack installation

Bench-top unit

–40 … +65 °C

+ 5 … +50 °C

+ 5 … +40 °C

Relative humidity ≤80% at temperatures up to +31 °C decreasing

to 50% at +40 °C

Use Indoors only, height up to 2000 m

Pollution degree 2

Degree of protection IP20

IEC384 class1, VDE 0411, part 2.80

Measurement boards

Interface and relay boards

2 (slot A and B)

1 (slot C)

Pirani / Cold cathode combined CP300C9

Profibus-DP interface and

relays

IF300P

1×10

-11

… 1000 mbar (depending on the

measurement boards used (→[1])

Setpoint

Relays

8 parameters – lower and upper threshold

8 relays

Error display

Relays

red LED

1 relays

Radiation resistant no

Vertical, max.

Horizontal, max.

21 mT (3 dB), 15 mT (6 dB)

11 mT (3 dB), 8 mT (6 dB)

Mains Power Connection

Ambiance Conditions

Safety

Slots for Plug-In Boards

Compatible Measurement

Boards

Compatible Interface and Relay

Boards

Measurement Range

Setpoint / relays

Error display / relays

Radiation resistant

Magnetical field

(under construction)

IG9970BEN (2017-04) TPG300.om

9

Manually

Computer controlled

by 4 push buttons (keys) on the front panel

via RS232C, RS422 or Profibus-DP interface,

depending on the interface relay boards used

(→[1]

Measurement range depending on the measurement boards used

→[1]

Measurement rate

Display rate

100 Hz

5 Hz

Filter time constant

Fast (FI 1)

Normal (FI 2)

Slow(FI 3)

≈16 ms

≈160 ms

≈1.6 s

Measurement unit mbar, Torr, Pa

Display 15 mm high numbers, 7 segment LED

Rack mounted, panel mounted or bench top.

1.35 kg (without plug-in boards)

235 2.5

316

sensor set point

sensor off

sensor on

set up

step funct group

1 2 3 4 A B

mbar

Torr

Pa

A1

A2

B1

B2

PE

PE

0 10

127

141.9

122.5

128.5

ø3.5

111.6

137.5

Operation Controls

Measured Values

Dimensions [mm]

Installation Modes

Weight

10

IG9970BEN (2017-04) TPG300.om

4 Installation

DANGER

Putting a product which is visibly damaged into operation can be ex-

tremely hazardous. If the product is visibly damaged do not put it into

operation and make sure it is not inadvertently put into operation.

Skilled personnel

The unit may only be installed by persons who have suitable technical

training and the necessary experience or who have been instructed by

the end-user of the product.

The TPG300 can be installed in a 19" rack, a control panel or operated as a desk

top unit.

The TPG300 is designed for installation in a 19" rack frame, built according to the

DIN 41 494 standard (screws and plastic parts are supplied with it).

DANGER

DANGER: protection class of the rack

If the product is installed in a rack, it is likely to lower the protection

class of the rack (protection against foreign bodies and water) e.g.

according to the EN 60204-1 regulations for switching cabinets.

Take appropriate measures for the rack to meet the specifications of

the protection class.

Install rack chassis adapter in rack cabinet and slide TPG300 into the adapter.

Secure TPG300 with the screws supplied with it.

The temperature inside the rack must not exeed the maximum

admissible temperature (→8).

Height 3U

M2.5

4.1 Installation

4.1.1 Rack Installation

Installation in a

Height 3 U Rack Chassis

Adapter

IG9970BEN (2017-04) TPG300.om

11

DANGER

DANGER: protection category of the control panel

If the product is installed in a rack, it is likely to lower the protection

category of the rack (protection against foreign bodies and water) e.g.

the EN 60204-1 regulations for switch cabinets.

Take appropriate measures for the control panel to meet the

specifications of the protection category.

For mounting the TPG300 into a control panel, the following cut-out is required:

For reducing the mechanical strain on the front panel, preferably support the unit.

Slide the TPG300 into the cut-out of the control panel and secure it with four

M2.5 … M3 (or equivalent) screws.

The temperature inside the cabinet must not exeed the maximum

admissible temperature (→8).

M2.5 ... M3 or ø3 ... 3.5

122.5

113

139

127

4.1.2 Installation in a Control

Panel

12

IG9970BEN (2017-04) TPG300.om

The TPG300 is also suited for use as desk-top unit. For this purpose, a conversion

kit is available (→42).

Push the eight press nuts supplied with the kit into the appropriate holes in

the side panels.

Fit slotted Cover and secure it with the screws supplied.

4.1.3 Use as Desk-Top Unit

Desk-Top Conversion

IG9970BEN (2017-04) TPG300.om

13

Mount folding stands and rubber feet onto angle profiles.

Turn over the TPG300 and fix both angle profiles to the TPG300 side

panels as shown.

Used as a desk top unit, the temperature inside the cabinet must not

exceed the maximum admissible temperature due to the influence of

external heat sources (→8).

14

IG9970BEN (2017-04) TPG300.om

DANGER

DANGER: line voltage

Incorrectly grounded products can be extremely hazardous in the

event of a fault.

Use only a 3-conductor power cable with protective ground. The power

connector may only be plugged into a socket with a protective ground.

The protection must not be nullified by an extension cable without

protective ground.

DANGER

No mains line fuse

The TPG300 has no fuses accessible by the end user.

The line power socket for the TPG300 has to be fused with max. 10 A.

DANGER

Grounding screw for internal protective ground

The internal protective ground is connected to the TPG300 power

supply rear panel with a grounding screw.

Do not turn or loosen grounding screw.

A 2.5 m mains cable is delivered with the TPG300. If its plug is not compatible with

your local power system, replace the cable to suit the local circumstances. Use

only a 3-conductor cable with protective ground.

If the TPG300 is installed in a rack cabinet, the use of a switched mains distributor

is strongly recommended.

Internal protection ground,

do not loosen screw

4.2 Mains Power

Connection

IG9970BEN (2017-04) TPG300.om

15

In most cases, the TPG300 is supplied ready for operation, (with the plug-in boards

already installed). In addition, in units for combined measurement of medium and

high vacuum, the high vacuum measuring circuit is controlled automatically accord-

ing to pressure. This is because switching function A and / or B is factory assigned

to a medium vacuum measuring circuit (→21).

The controlling Pirani gauge and the controlled cold cathode gauge must both be

connected to the same vacuum chamber to guarantee efficient operation.

Further information and details on installing/removing plug-in boards and handling

of empty slots you find in [1].

Electrical connections of gauges, analog signals, relays contacts etc. depend on

the plug-in boards used and are described in [1] in detail.

4.3 Installing / Removing

plug-in boards

Factory Configuration

Installing / Removing Plug-in

Boards

4.4 Connecting plug-in

boards

16

IG9970BEN (2017-04) TPG300.om

5 Operation

Status messages will be shown on the display instead of the measured value

(→20, 39).

Before switching the unit on, check that all plug-in boards, connection cables and

gauges are installed correctly and that the technical requirements are satisfied.

The mains power switch is located on the back panel of the unit.

To switch the TPG300 on, operate the mains power switch (or the centrally

switched mains power distributor in case of installation into a rack).

After the power has been switched on …

•The unit performs a self-test

•It reactivates the parameters in effect before the unit was switched off

•All measuring circuits with activated hot start (→33) and all operational Pirani

gauges are switched on

•The measurement value of the first measuring circuit in operation is displayed.

To switch the TPG300 off, operate the mains power switch (or the centrally

switched mains power distributor in case of installation into a rack).

Wait at least 10 seconds before switching the TPG300 on again to allow

the unit to initialize itself properly.

sensor set point

sensor off

sensor on

set up

step funct group

Mantissa Exponent

Measurement value display

Overrange/underrange

Identification of plug-in board Unit of measurement

Status display

cold cathode gauges

Error lamp

100

Operation prompt for combined keys

Bar graph display

(linear mantissa indication)

1 2 3 4 A B

Status of

switching functions,

lights if status = ON

set point

funct group

Change to

»set up« mode

Change to

»set point« mode

sensor

Select

»sensor«

Selected sensor display

5.1 Front panel

Status Messages

5.2 Switching TPG300 On

and Off

Switching TPG300 On

Switching TPG300 Off

IG9970BEN (2017-04) TPG300.om

17

The measured pressure depends on the gas type present. It is referenced to nitro-

gen (N

2

). For other gases please refer to the characteristic curves shown in the

appendix of

[1].

If you intend to use the measurement results for control functions, allow for the time

constants of the TPG300, the gauges, possible ignition delays etc., until valid

measurements are displayed (

→

[1], [3]).

A generally applicable statement on the accuracy of the measurement cannot be

made. The type of gas being measured is a major factor affecting the accuracy,

and so is the current condition of the gauge.

The accuracy of the gauge at any particular moment can only be assessed by

comparing the results with a reference unit. Calibration pumping systems are

available for reliable measurements, particularly for pressures under 10

-4

mbar.

Cold cathode measuring circuits are factory aligned and require no recalibration.

Pirani measuring circuits are factory prealigned. For accurate measurement

→[1].

The TPG300 has three operating modes:

•»sensor«

Pressure measurement (→19)

Selection of the measuring circuit (→19)

Switching gauges on/off (→20)

•»set point«

Display of the switching function parameters (→22)

•»set up«

Display of the unit parameters (→24)

Modification of the unit parameters (→25)

Execution of test programs (→35)

5.3 Measuring with the

TPG300

Gas Type Dependence

Validity of Displayed Data

Accuracy of measurement

Alignment

5.4 Operating Modes

18

IG9970BEN (2017-04) TPG300.om

Changing the operation mode to »set up« and some operations in »sensor« mode

require the input of a code, in case it has been assigned previously (→33).

By a flashing display («Co d») you will be reminded to input the correct number in

the following manner:

»sensor«

»set point«

»set up«

Code entry

if required

After 1 ... 2 Min.

Mains power on

Code Entry

required

0 ... 9

0 ... 9

0 ... 19

Unlocked

Changing the Operating Mode

Entering a Code

IG9970BEN (2017-04) TPG300.om

19

The »sensor« operating mode is the standard mode of the TPG300, showing

measurement value, status information or a plug-in board identification on the

display.

The TPG300 is in »sensor« mode …

After being switched on

•After the <sensor> key has been pushed

•1 … 2 minutes after the last keystroke in »set point« mode.

Quitting the »sensor« mode …

•Switch the mains power switch of the TPG300 off

•Push the <set point> key (change to <set point> mode)

•Push the <set point> keys simultaneously and enter code, if required (change

to »set up« mode).

The following entries are possible in »sensor« mode:

Push simultaneously

Push simultaneously

(→22)

Push simultaneously (→24)

5.5 Operating Mode

»sensor«

5.5.1 Key Entries

Select

Measuring Circuit

Switch On

Selected Gauge

Switch Off

Selected Gauge

Change to »set point« Mode

Change to

»set up« Mode

20

IG9970BEN (2017-04) TPG300.om

Each individual measuring circuit can be manually switched on or off with <step>

and <funct> (after entering the code →33).

Manual on/off-switching has priority over the automatic control.

Measured value is displayed:

Switch on cold cathode gauges at pressures <10

-3

mbar only, in order to

prevent excessive contamination of the gauges.

When the cold cathode measuring circuit is switched on, the lamp «PE»

on the front panel lights up.

The plug-in board identification is displayed (→21):

Pirani gauges are not deactivated by switching them off, only their

measuring results and the error message are suppressed.

Switching off the cold cathode gauge helps to prevent it from becoming

contaminated.

If the measured value is outside the measuring range of the measuring circuit, this

will be indicated if the corresponding measuring circuit is selected.

If the cold cathode measuring circuit is controlled by another measuring circuit, the

display changes over automatically.

Overrange: «or» and exponent indicating the range limit:

If the upper measuring range limit is exceeded, the cold cathode gauge

can become contaminated if it remains switched on.

Underrange: «ur» and exponent indicating the range limit:

If the under range control is switched off the system cannot distinguish between a

gauge failure, cable interruption and underrange of a cold cathode measuring

circuit. «ur» is displayed in all cases.

1 2 3 4 A B

mbar

Torr

Pa

A1

A2

B1

B2

PE

PE

0 10

1 2 3 4 A B

mbar

Torr

Pa

A1

A2

B1

B2

PE

PE

0 10

1 2 3 4 A B

mbar

Torr

Pa

A1

A2

B1

B2

PE

PE

0 10

1 2 3 4 A B

mbar

Torr

Pa

A1

A2

B1

B2

PE

PE

0 10

5.5.2 Switching the Measuring

Circuit On / Off

Measuring Circuit Switched

On

Measuring Circuit Switched

Off

5.5.3 Measurement Range

Violation

Overrange

Underrange

Other manuals for TPG300

1

Table of contents

Other Inficon Controllers manuals

Inficon

Inficon TPG300 User manual

Inficon

Inficon Cygnus 2 User manual

Inficon

Inficon VGC031 User manual

Inficon

Inficon VGC031 User manual

Inficon

Inficon CU1000 User manual

Inficon

Inficon VGC083A User manual

Inficon

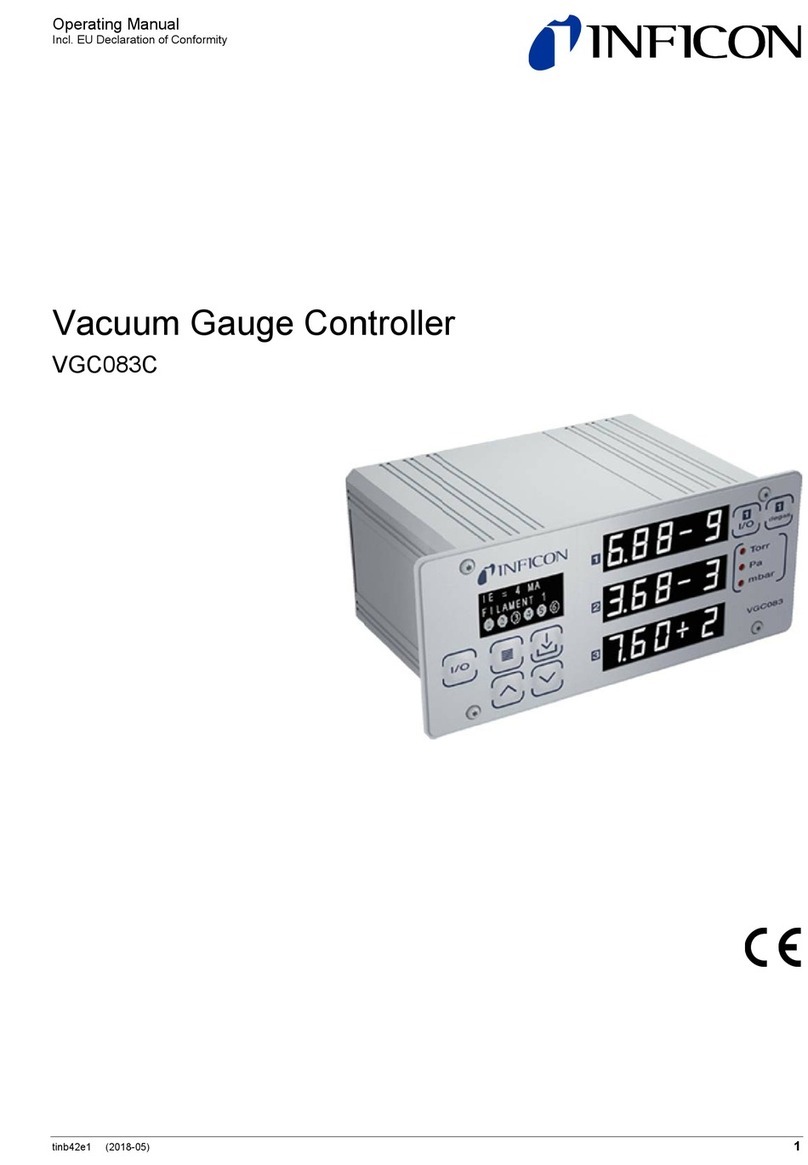

Inficon VGC083C User manual

Inficon

Inficon IC6 User manual

Inficon

Inficon VGC083B User manual

Inficon

Inficon SQC-310 User manual

Popular Controllers manuals by other brands

TIANJIN BAILI ERTONG MACHINERY

TIANJIN BAILI ERTONG MACHINERY SMC Series Operation manual

Novus

Novus N20K48 user guide

Sunlight Supply

Sunlight Supply TITAN CONTROLS Helios 5 instruction manual

Renogy

Renogy ROVER Series manual

Honeywell

Honeywell PW-6000 Installation and configuration guide

gefran

gefran ADV200 Series manual