STW81V 12380-0710-00 Page 5 / 8 www.ziehl.de

8 Important notes

9 Installation

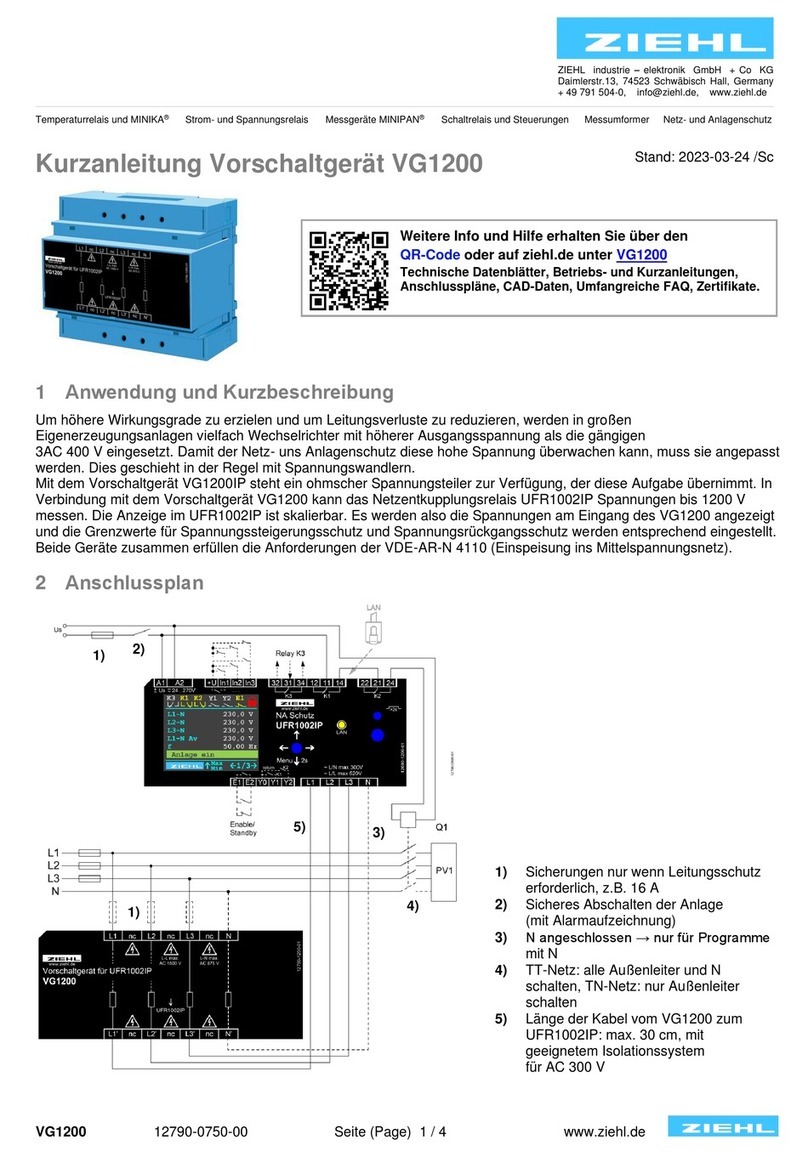

The unit can be mounted as follows:

mounting of the distributor on a 35 mm mounting rail according to EN 60715.

using M4 screws for wall mounting. (additional screws are not included)

make the connection in accordance with the wiring diagram or the nameplate

Switch on the control voltage.

When the device is ready for operation, the relay must activate, when a current greater than the Ion response

value flows through one of the current transducers.

WARNING!

Dangerous electrical voltage!

May cause electric shock and burns.

Disconnect the system and equipment from the power source before starting any work.

Caution!

Only one live wire may be fed through the current transducer!

Failure-free and safe operation of the equipment requires that it is properly transported and stored,

professionally installed and commissioned, and operated as intended.

Work on the unit may only be performed by persons who are familiar with the installation, startup and

operation of the unit and who have the necessary qualifications for this works. They must comply with the

operating manual, the instructions placed on the device and the relevant safety regulations for the

installation and operation of electrical systems.

The devices are built and tested according to DIN VDE/EN/IEC standards and leave the factory in perfect

safety condition.

To maintain this condition, follow the safety instructions in the manual marked "Caution". Failure to follow the

safety instructions could result in death, personal injury, or property damage to the device itself and to other

units and equipment.

If the information in the manual is not sufficient, please contact us directly or your sales agent.

Instead of the industrial standards and regulations mentioned in the operating manuals and applicable in

Europe, observe any relevant regulations valid in the country of use, should the device is operated outside

the above area.

Install a circuit breaker marked as a isolating device and an overcurrent protection

device (rated current ≤ 10 A) in the power line near the unit (easily accessible).

Observe the maximum permissible temperature when installing in the control box. Ensure adequate

distance from other appliances or heat sources. If cooling is impeded, e.g. by close proximity to equipment

with a higher surface temperature or hindered cooling air flow, the permissible ambient temperature will be

reduced.

Caution

Before connecting the unit to the mains supply, make sure that the Us control voltage on

the side rating plate corresponds to the mains voltage connected to the unit!