Non-Sound Decoder MX600 - MX638 and Sound Decoder MX640 - MX659 Page 5

2 Technical Information

Allowable track voltage ............................................................................................................. min. 10 V

MX620, MX640 (discontinued), MX616 .......................................................................... max. 24 V

MX600 …………………………………………………………………… ........... ……………... max. 30 V

MX617,MX618,MX621,MX622,MX623,MX634 ............................................................... max. 35 V

MX646,MX647,MX648,MX649,MX658 ........................................................................... max. 35 V

MX630,MX631,MX632,MX633,MX644,MX645 … digital or DC-analog .......................... max. 35 V

MX630,MX631,MX632,MX633,MX634,MX644,MX645 with AC analog, … max. pulse... 50 V

max. continuous motor current: MX616, MX617, MX618, MX620, MX621, MX649 .......................... 0,7 A

MX600, MX622, MX623, MX648, MX658 ........................................ 0,8 A

MX630, MX631, MX646 .................................................................. 1,0 A

MX633,MX634,MX640,MX642,MX643,MX644,MX645..................... 1,2 A

MX632 ............................................................................................ 1,6 A

Adapter board ADAPLU or ADAMTC with decoder ......................... 1,8 A

Peak motor current: MX600, MX616, MX617, MX618, MX620, MX621, MX623, MX646 ................ 1,5 A

MX648, MX649, MX658.................................................................................. 1,5 A

MX630 to MX634, MX640 to MX645 for about 20 sec ................................... 2,5 A

Maximum total function output, continuous *) MX616, MX617, MX618, MX620................................ 0,5 A

MX621,MX646 to MX658 ......................................................... 0,5 A

MX630 to MX634, MX640 bto MX645 ...................................... 0,8 A

Maximum continuous current for LED outputs .. MX640,MX642,MX644 ................................. 10 mA each

Maximum continuous total current (motor and functions) .............. = maximum continuous motor current

opperating temperature .................................................................................................... - 20 to 100 °C

MX640 to MX660: Sound sample memory .................................................. 32 Mbit (= 180 sec at 22 kHz)

MX640 to MX660: Sample rate ..............................................depending on sound sample... 11 or 22 kHz

MX640 to MX660: Number of independent sound channels ................................................................... 6

MX640 to MX660: Sound amplifier output (Sinus) ................ (MX640,MX646,MX648) 1,1 W, (others) 3 W

Speaker impedance ................................................... (MX640,MX646 to MX660) 8 Ohm, (others) 4 Ohm

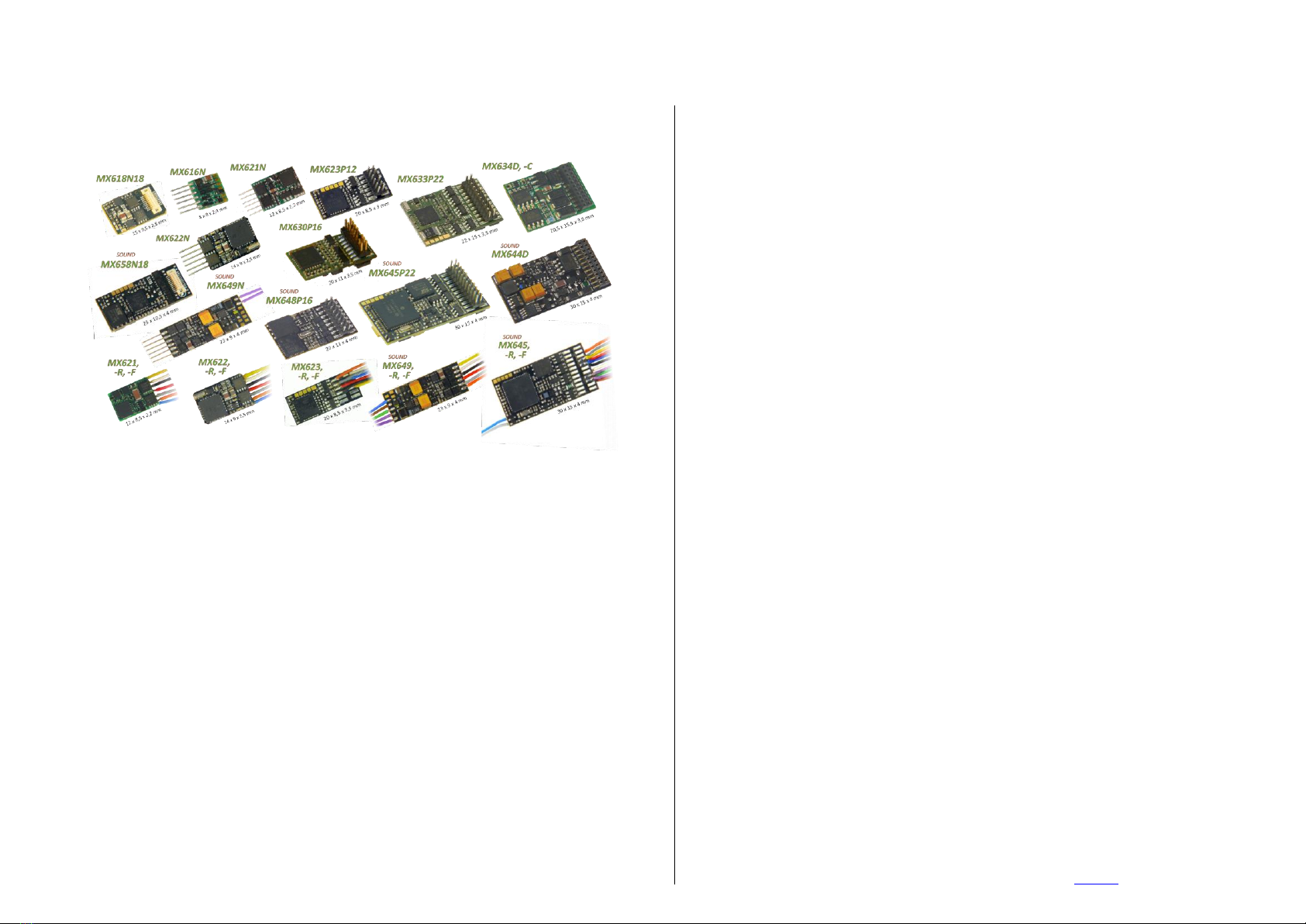

Dimensions (L x W x H) …... MX600, MX600P12 ............................................................. 25 x 11 x 2 mm

MX616 ................................................................................. 8 x 8 x 2.4 mm

MX617 ................................................................................ 13 x 9 x 2.6 mm

MX618 ............................................................................. 15 x 9,5 x 2.8 mm

MX620, MX620N (excluding pins) ....................................... 14 x 9 x 2.5 mm

MX621, MX621N (excluding pins) .................................... 12 x 8,5 x 2.2 mm

MX622, MX622P16 (height without pins) ............................ 16 x 9 x 2.5 mm

MX623, MX623P16 ......................................................... 20 x 8.5 x 3.5 mm

MX630, MX630P16 (height without pins) .......................... 20 x 11 x 3.5 mm

MX631, MX631D/C, MX634, MX634D/C ....................... 20.5 x 15.5 x 4 mm

MX632, MX632D .............................................................. 28 x 15.5 x 4 mm

MX633, MX633P22, MX637 ...............................................22 x 15 x 3.5 mm

MX635, MX636...................................................................26 x 15 x 3.5 mm

MX634, MX638.............................................................20.5 x 15.5 x 3.5 mm

MX646, MX646N ............................................................... 28 x 10.5 x 4 mm

MX648, MX648P16 (height without pins) .............................. 20 x 11 x 4 mm

MX648N, MX649N (without pins) ........................................... 23 x 9 x 4 mm

MX640 .............................................................................. 32 x 15.5 x 6 mm

MX642, MX643, MX644, MX645 ......................................... 30 x 15 x 4 mm

MX658 .............................................................................. 25 x 10.5 x 4 mm

MX659 ................................................................................ 20 x 9.5 x 3 mm

MX660 .................................................................................42 x 9 x 4.2 mm

Adapter boards ADAPLU -MTC

with decoder

......... 45 x 15 (26,5) x 4 (6) mm

*) The short circuit protection is carried out for the total current of all outputs. Use the “soft start” option (i.e. CV #125 = 52) to prevent

cold-start problems of light bulbs (in-rush current interpreted as a short circuit, which leads to the output being turned off)!

The decoder type can be read out in CV #250: 190=MX659 199=MX600 200=MX82 201=MX620

194=MX660 195=MX616 196=KISS Silberlinge 197 = MX617 198=FLM_E69

199= MX600 200=MX82 201=MX620 202=MX62 203=MX63

204=MX64 205=MX64H 206=MX64D 207=MX680 208=MX690

209=MX69 210=MX640 211=MX630-P2520 212=MX632 213=MX631

214=MX642 215=MX643 216=MX647 217=MX646 218=MX630-P25K22

219=MX631-P25K22 220=MX632-P25K22 221=MX645 222=MX644 223=MX621

224=MX695-RevB 225=MX648 226=MX685 227=MX695-RevC 228=MX681

229=MX695N 230=MX696 231=MX696N 232=MX686 233=MX622

234=MX623 235=MX687 236=MX621-FLM 237=MX633 238=MX820RevA

240=MX634 241=MX686B 242=MX820RevB 243=MX618 244=Roco NextG

245=MX697 246=MX658 247=MX688 248=MX821 249=MX648-RevC,D

250=MX699 251=Roco 2067 252=Roco ICE 253=MX649 254=MX697-RevB

Software Update:

ZIMO DCC decoders can be updated by the user. An update device such as the ZIMO decoder up-

date module MXDECUP, from 2011 MXULF, system-cab MX31ZL or command station MX10 is

required. The update process is carried out by a flash drive (MXULF, MX31ZL / MX10) or by a PC

with Windows operating system and the program ZIMO Firmware Flasher (in the bundle with ZSP).

The same hardware, but ZSP (software) is also used for uploading sound projects into ZIMO sound

decoders.

There is no need to remove the decoder or to open up the locomotive. Just set the locomotive on a

section of track connected to the update module and start the update with the computer or other

equipment mentioned above.

NOTE: Equipment inside the locomotive that is powered directly from the track (not through the de-

coder) can interfere with the update procedure. The same is valid for energy buffers that are in-

stalled without heeding the advice in the “Installation and wiring” chapter, section “Use of an external

energy source” (regarding a choke coil).

See the last chapter in this manual for more information on updating decoders or www.zimo.at!

Of course, SW updates can be done by ZIMO or your ZIMO dealer for a small fee.

Overload and Thermal Protection:

The motor and function outputs of ZIMO decoders are designed with lots of reserve capacities and

are additionally protected against excessive current draw and short circuits. Cut-outs are encoun-

tered if the decoder is overloaded.

Even though the decoder is well protected, it is not indestructible. Please pay attention to the following:

Wrong decoder contact, if, for instance, the motor leads have contact to track power or an overlooked connection

between the motor brushes and rail pick-ups is not always recognized by the overload protection circuit and could

lead to damage of the motor power amplifier or even a total destruction of the decoder.

Unfit or defective motors (e.g. shorted windings or commutator) are not always recognized by their high current

consumption, because these are often just short current spikes. So, they can lead to decoder damage including

damage to power amplifiers due to long-term exposure.

The power amplifiers of loco decoders (motor as well as function outputs) are not only at risk of overcurrent but al-

so voltage spikes, which are generated by motors and other inductive consumers. Depending on track voltage,

such spikes can reach several hundred volts and are absorbed by special protection circuits inside the decoder.

This is why the voltage shall not be too high, i.e. not higher than intended by the corresponding vehicle.

All ZIMO decoders are equipped with temperature sensors to measure their own operating temperature.

Power to the motor will be turned off once that temperature exceeds 1000C. The headlights start flashing

rapidly, at about 5 Hz, to make this state visible to the operator. Motor control will resume automatically af-

ter a drop in temperature of about 200C, typically in about 30 seconds.