OVERLOAD PROTECTION:

As is the case with all ZIMO decoders, the outputs of the MX82 are protected

againstexcessivecurrentdraw andshortcircuits.Anyoutputisturned offifanover

-

load situation exists. After that, the decoder keeps testing the affected output,

which often results in flashing lights.

Eventhough thedecoder iswellprotected, do notassume thatitisindestructible.Pleasepayat-

tention to the following:

Faultydecoder connection;connecting themotorleadsto trackpowerfor instance oranoverlooked

connectionbetweenthemotor brushesandrail pick-up’scausesshortsthatare notalwaysrecognized

by theoverloadprotectioncircuitandcouldleadtomotor endstage damageoreven totaldestruction of

the decoder.

Unfit ordefectivemotors; a shortedwindingor commutatoris notalwaysrecognized by the high cur-

rentconsumption it causes, because these are often just short spikes. They can lead to decoder

damage, including damage to end stages due to long time exposure.

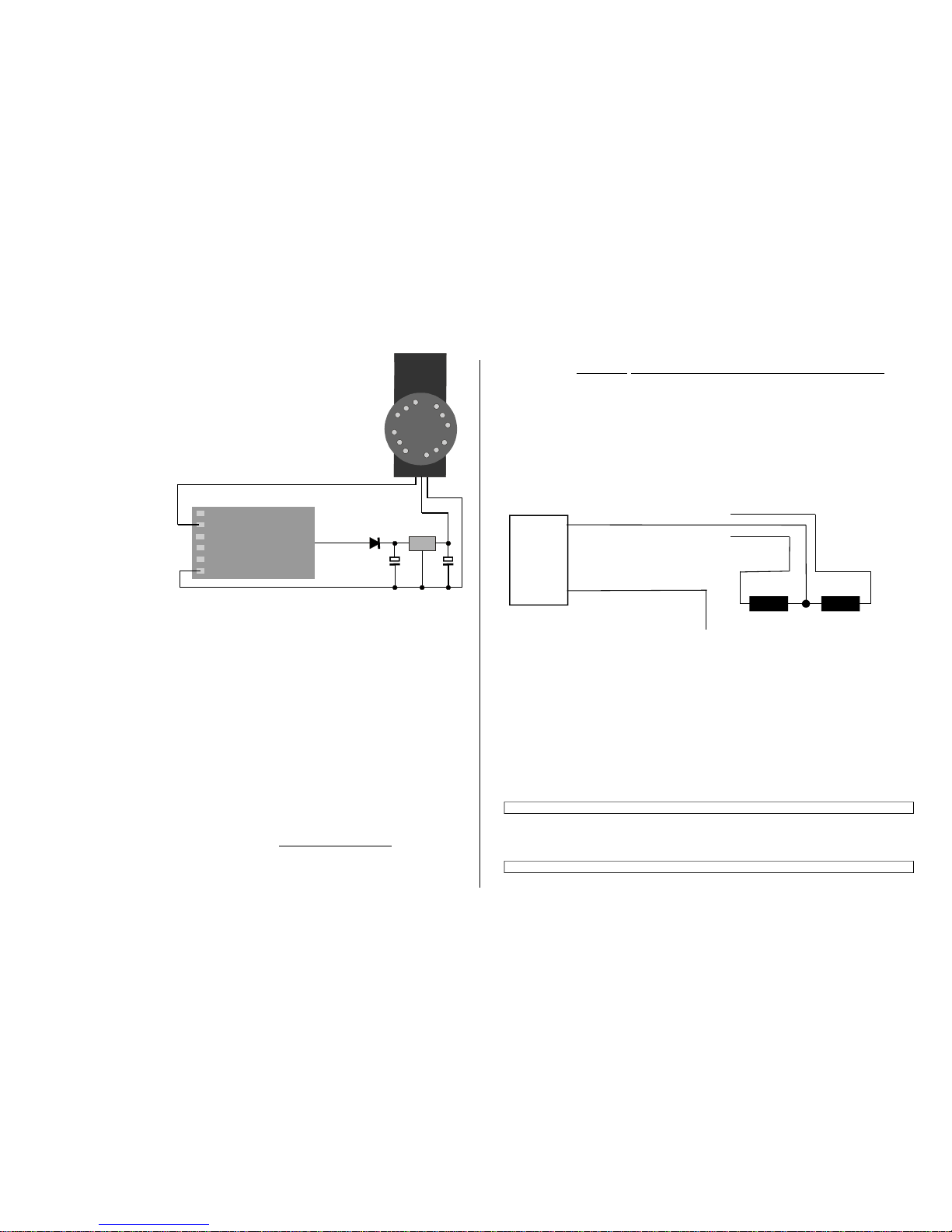

Voltagespikes whichcanbeinduced frommotorsandotherloadsconnected toadecodermaybe

responsible formore decoder damage thanexcessive current draw. Theheight of suchvoltagespikes

depends on the trackvoltage selected and can reach several hundred volts. They will be removedby

specialovervoltageprotection circuits butthecapacityandspeed ofsuchelementsislimited. Don’tse-

lecta higher trackvoltagethan whatisrecommendedfor therolling stockused on the layout. The full

range (up to 24V), adjustable with a Zimocommandstation, should only be utilized in special cases.

Even though Zimodecoderscan be operated at 24 Volts (MX62 at 20V), thatis not thecase if used in

conjunctionwith some other function elements built into a locomotive.

THERMAL PROTECTION:

Alldecoderscoveredinthismanualhave theability tomeasure theirownoperating

temperature. Power to the motor will be turned off once the temperature of the

decoderexceeds 100oC. The headlights start flashing rapidly, atabout 10 Hz, so

that theoperator can recognize this state. Motor control willresumeautomatically

after a drop in temperature of about 20oC, typically in 30 to 60 seconds.

3. Addresses and Programming

Incontrastto locodecoders,accessorydecoders require not only anaddress but

also asubaddress (2 sub addresses for theMX82V).The address is required for

decoder access with a cab, and the sub address determines with which function

key the turnout will be operated..

Althoughthe MX82maybeinstalled immediately, anaddresshas tobe assignedbefore itiscon-

nected to the layout wiring!

Assigning a new address is not possiblewithseveral MX82 connected in parallel to the track or

power bus; if tried, all MX82 would receive the same address.

PROGRAMMING PROCEDURES:

Detailed procedures (service mode and operational mode) for program-

mingandreadingofaddressesandconfigurationvariablesarefoundinthe

instruction manual for the cab (e.g. MX21).

Programming is even simpler and more convenient with the help of a computer and ADaPT

software (E.Sperrer, software developer)!

Technical note to acknowledgment/read-out during “service mode” programming:

Whenprogrammingadecoderwithacaborcomputer,everysuccessfulprogrammingstepwillbemade

visiblebythedecoder.Thesameacknowledgmentmethodisusedwhenreadingtheconfigurationvari-

ables.

The decoder acknowledgment is carried out by briefly turning the motor and headlights on, causing

shortpowerpulsesthatthecommandstationrecognizes.Acknowledgmentandread-out ofadecoderis

onlysuccessful ifthecurrentconsumption is high enough, which means that the motor and headlights

have to be connected or at least one of the two.

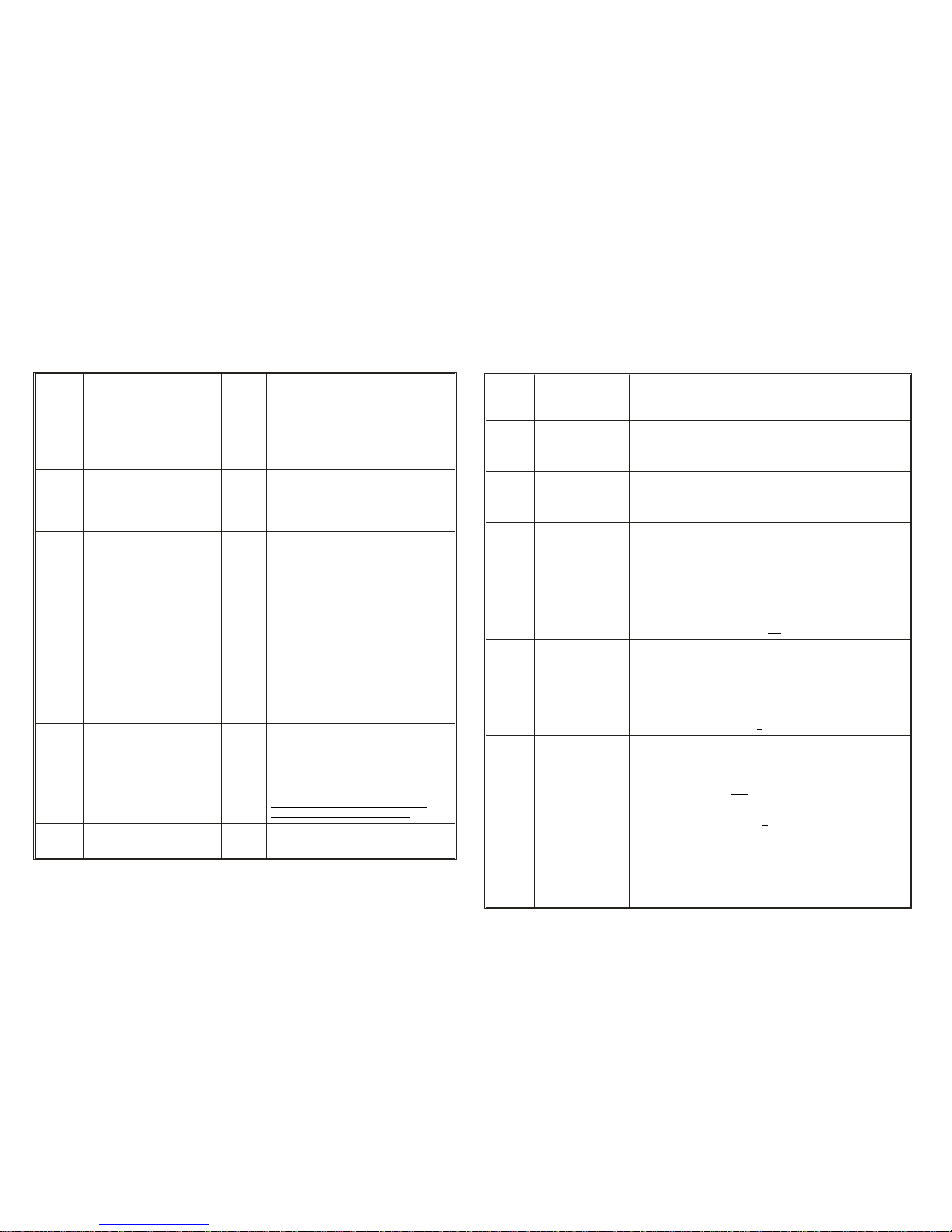

The meaning of Configuration Variables (CV’s) are in part standardized by the

NMRA DCC RECOMMENDED PRACTICES, RP-9.2.2. There are however

certainCV’sthatareforZimo decoders only, insomecasesexclusivelyfor specific

types.

Always use the specifications for the decoder in question, since the value range

may differbetween manufacturers, even with standardizedCV’s; inthiscase use

the table below.

ACCESSORY DECODER MX82 Page 3

Programming in

“Service mode” ”Operations mode”

Decoder or turnout with decoder on Decoder connected to main track.

programming track (socket: ”PROG”).

Addresses and CV programming. Programming of configuration variables only.

Secure programming with Programming without acknowledgement (commands

are sent repeatedly, which increases reliability)

Read-out of configuration variables and Read-out of configuration variables is not possible.

address is possible. (Later possible with “bi-directional communication”).

Start procedure with “E” and “MAN” keys. Start procedure with “E” and “F” or “E” und “W”.

(”on-the-main”, MX1 -socket ”SCHIENE”),

acknowledgement.