Page 6 H0 Sound Decoder MX640

THE MX640 CONFIGURATION VARIABLES:

Configuration Variables can be defined within the programming procedures to improve the driving

characteristics of a locomotive and for many other application specific adjustments.

The meaning of Configuration Variables (CV’s) is in part standardized by the NMRA DCC REC-

OMMENDED PRACTICES, RP-9.2.2. There are however certain CV’s that are for Zimo decoders

only, in some cases exclusively for specific types of Zimo decoders.

Always use the specifications for the decoder in question, since the value range may differ between

manufacturers, even with standardized CV’s; in this case use the table below.

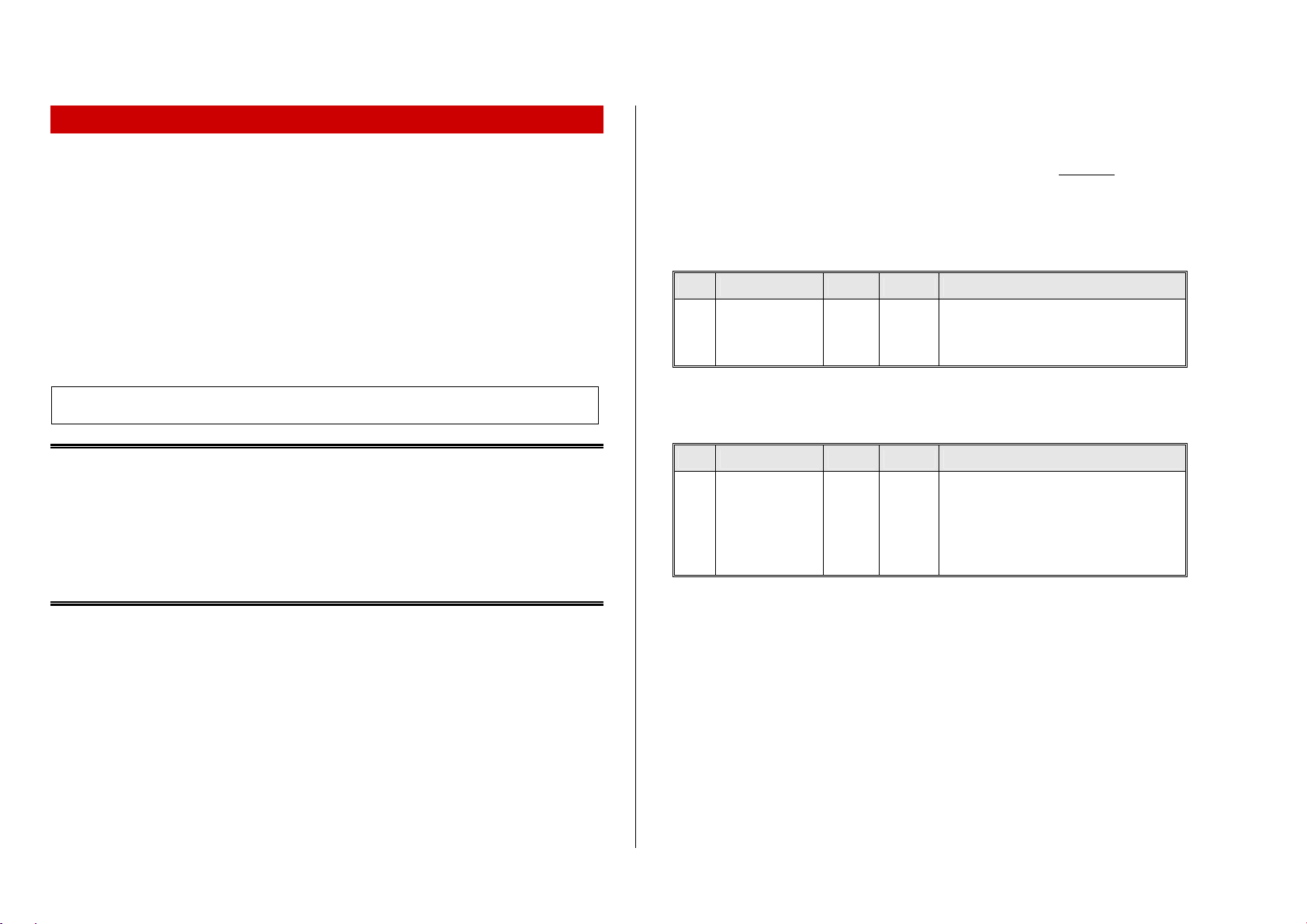

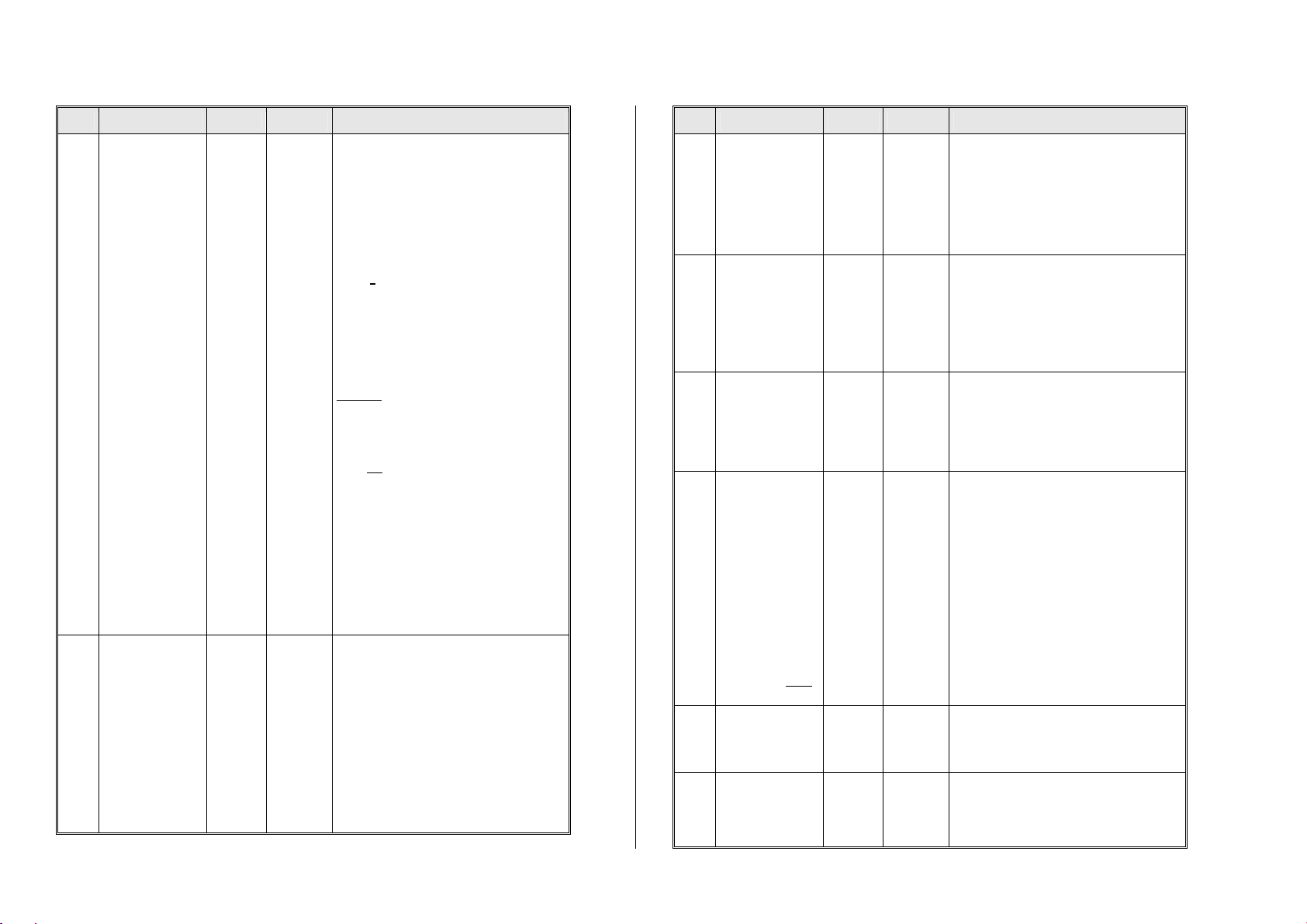

CV Designation Range Default Description

#1 Loco

address 1 – 127 3 The “short” (1-byte) loco addresses; Is active

when Bit 5 in CV #29 is 0.

#2 Vstart

1 – 252

(See add.

notes) 2

Entered value = internal speed step assigned

to lowest cab speed step.

Bit 4 in CV # 29 has to be 0; otherwise individ-

ual speed table is active.

#3 Acceleration rate 0 - 255 12 Multiplied by 0.9 equals’ acceleration time in

seconds from stop to full speed.

#4 Deceleration rate 0 - 255 12 Multiplied by 0.9 equals’ deceleration time in

seconds from full speed to complete stop.

#5 Vhigh

0 – 252

(See

add. notes) 1 (= 252)

Entered value = internal speed step assigned

to highest cab speed step, according to the

number of speed steps selected (14, 28 or

128).

0 and 1 = no effect.

Bit 4 in CV #29 has to be 0, otherwise speed

table is active.

#6 Vmid

1,

A useful

value for is

¼ to ½

of the

value in

CV #5

(See

add. notes)

1

( = about 1/3 of

top speed)

Entered value = internal speed step assigned to

the cabs center speed step (=step 7,14 or 63 ac-

cording to the number of speed steps selected: 14,

28 or128)

“1" = default (medium speed is 1/3 of full speed,

that is: with CV #5 = 255, CV #6 is 85, otherwise

lower).

Bit 4 in CV #29 has to be 0, otherwise speed table

is active.

The 3-point curve that results from the settings

in CV’s #2, 5, 6 is automatically smoothed out;

not jolt noticed at mid-speed!

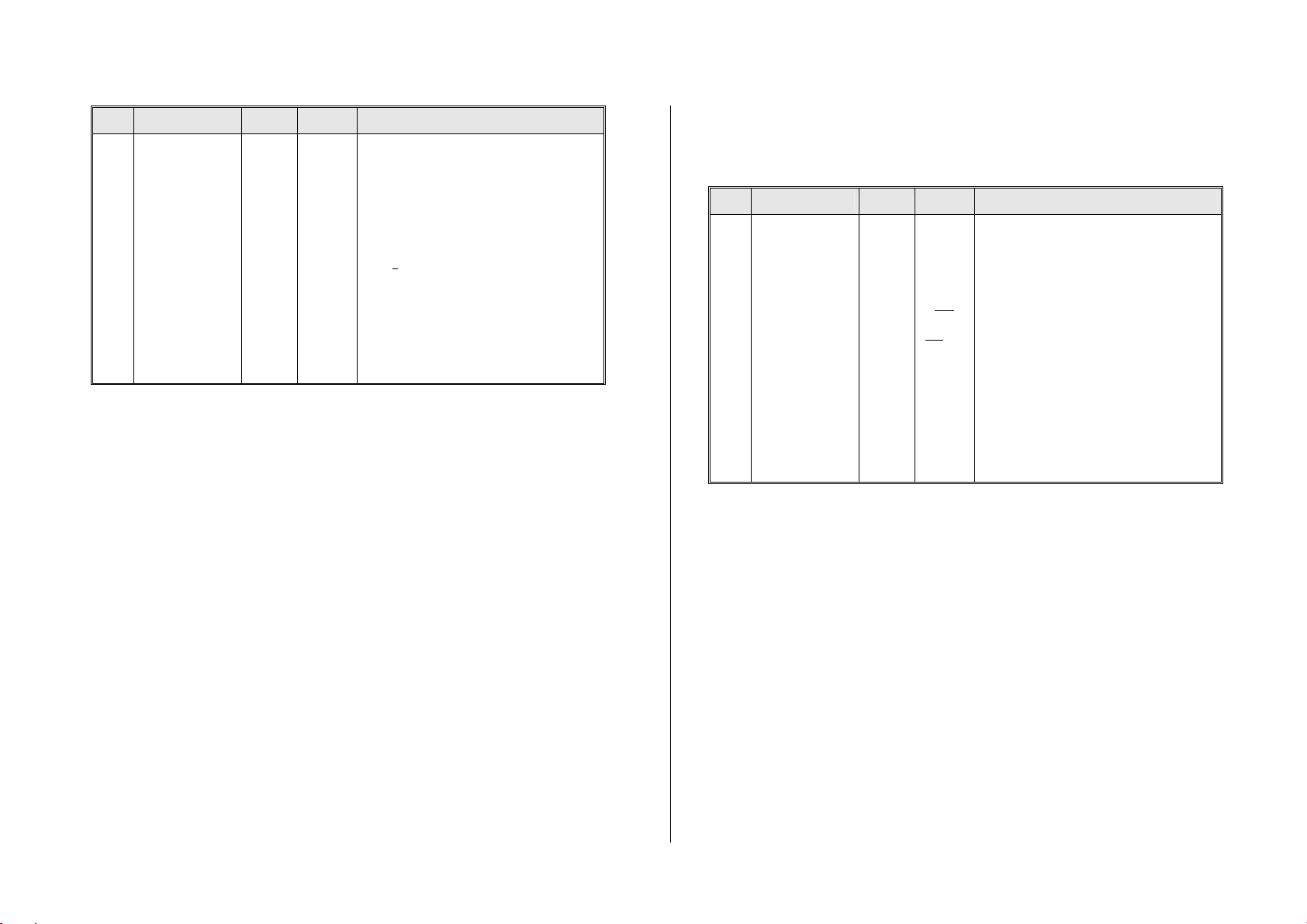

#7

Software version

and

Temporary register when

programming with a “Lok-

maus 2” and similar low

level systems.

Read only

Only version

number can

be read

Pseudo-

Programming

This CV normally displays the decoder soft-

ware version.

For user of Lokmaus 2 :

Pseudo-programming (because programmed

value is not really stored) as an initial step for

programming or read-out of a higher CV (#>99)

and/or a higher value (>99) for systems that

CV Designation Range Default Description

See section “Operation

within other systems” in this

manual.

And for

programming help of higher

CV numbers with „medium

level“ systems such as

Intellibox or Lenz; especially

for sound sample selection

and sound CV’s.

I.e. to program

CV #300 = 100

with values:

for

Lokmaus 2:

1, 2,

10, 11, 12,

20, 21, 22

And for

Sound-Prog:

110, 120,

130,

210, 220,

230

(see chap-

ter 6)

can only program a limited within a limited

number and value range :

Ones digit = 1: The entered CV value will be

increased by 100 during the actual program-

ming.

Ones digit = 2: …increases by 200.

Tens digit = 1: The entered CV number will be

increased by 100 during the actual program-

ming.

Tens digit = 2: ….increases by 200.

Tens digit = 3: ….increases by 300.

Hundredth digit = 1: CV number conversion is

retained until system is powered down.

= 2: ...is retained until reset

with CV #7 = 0.

For Lokmouse-2: see section „ZIMO decod-

ers in competitor systems“!

SOUND – selection and programming:

see chapter 6!

#8

Manufacturer ID

and

HARD RESET

with CV #8 = 8

or

LOADING

of special CV sets

Read only

all additional

programming

is pseudo

only; read-out

always shows

“145”, which is

ZIMO’s

assigned

number

145

( = ZIMO)

NMRA assigned manufacturer ID for Zimo is:

145 (”10010001”)

Pseudo-Programming (”Pseudo” = pro-

grammed value is not really stored):

CV #8 = “8” -> HARD RESET (NMRA standard:

all CV’s reset to default values).

CV #8 = “0” -> HARD RESET (ZIMO special: all

CV’s reset to currently stored sound project).

CV #8 = “9” -> HARD RESET for LGB-operation

(14 speed steps, pulse chain).

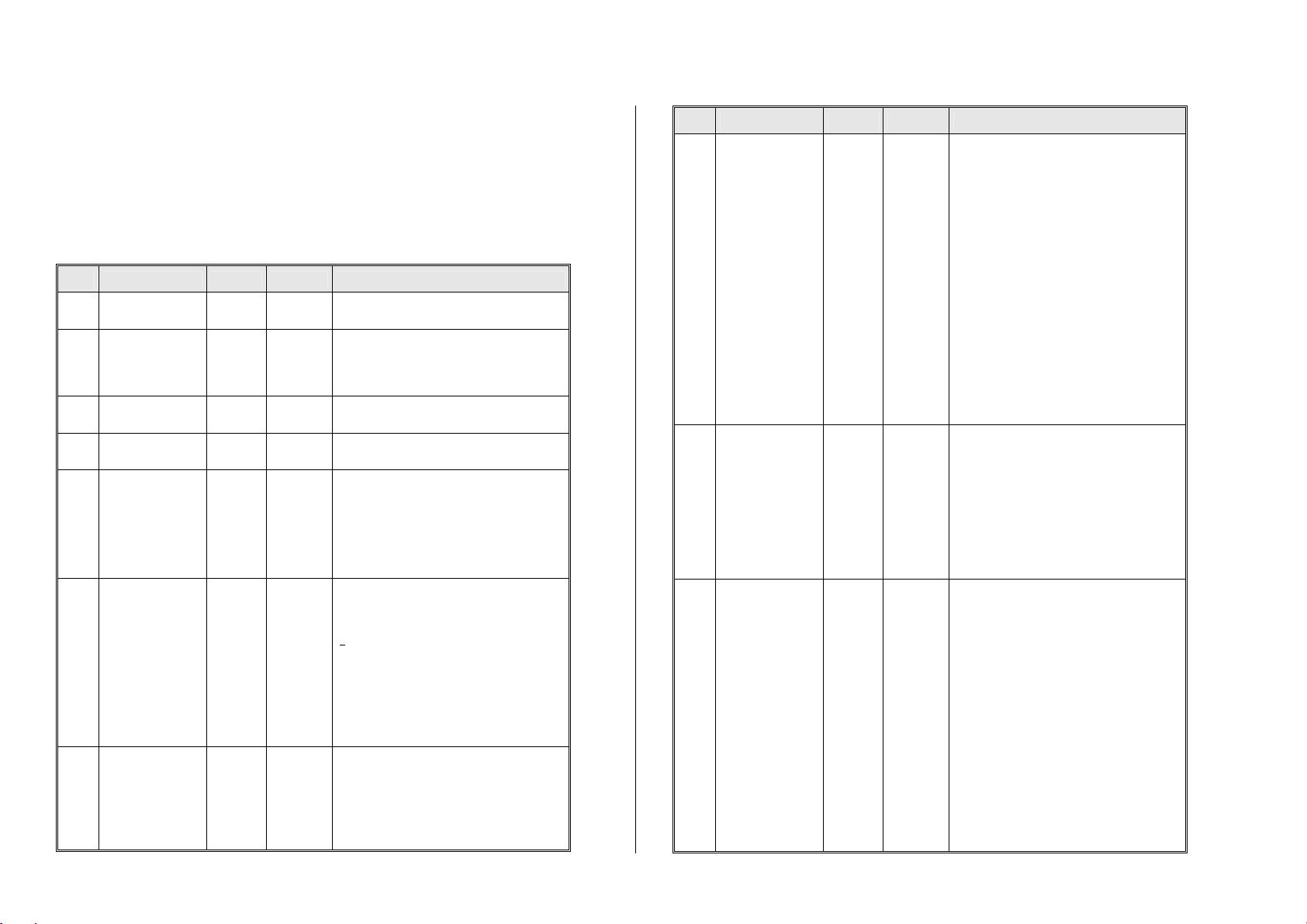

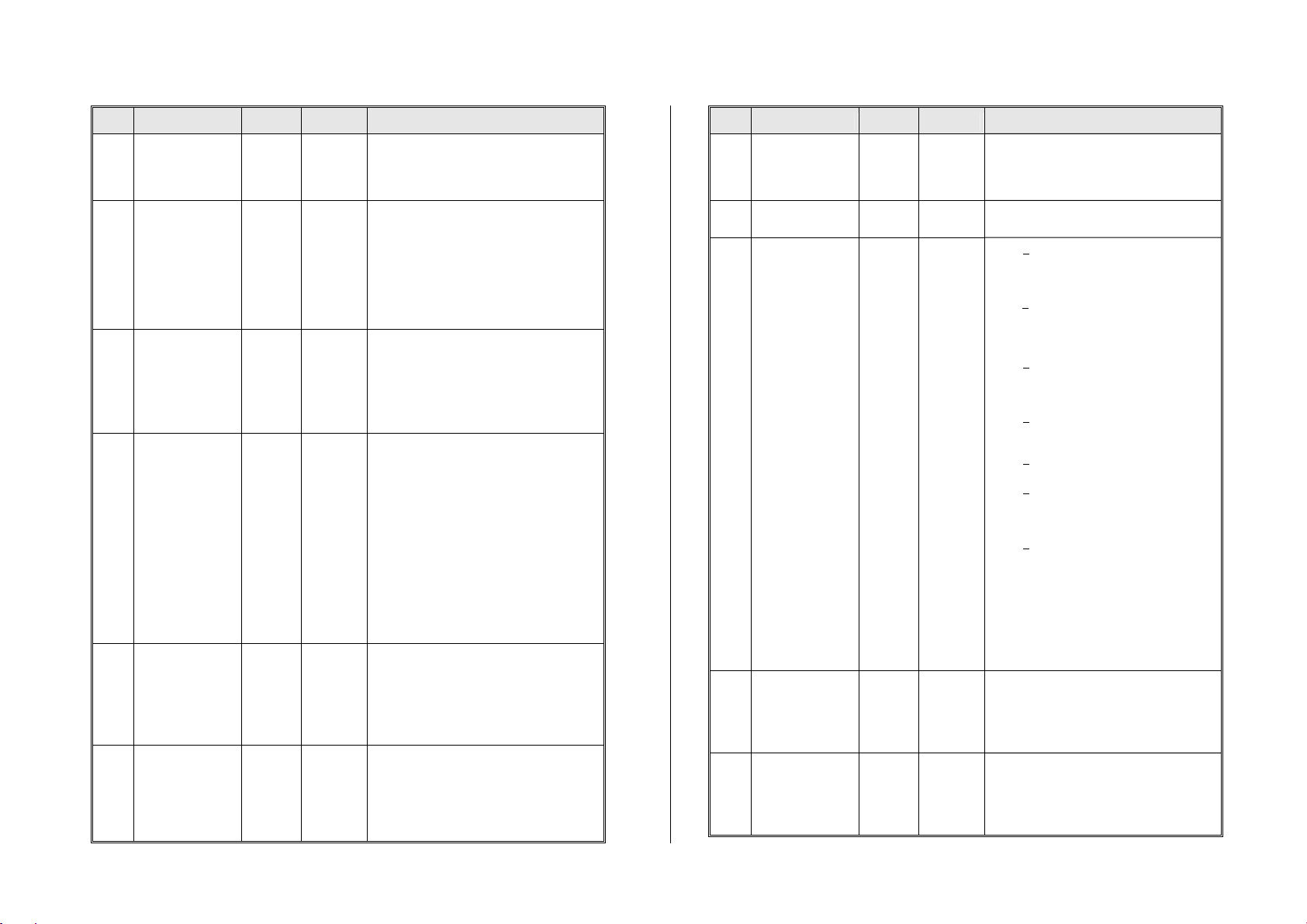

#9

Motor frequency

and

EMF

sampling rate

Recommendation

for coreless mo-

tors, i.e.

MAXXON,

FAUL-HABER:

CV #9 = 22 or 21

0

High

frequency,

mid-range

sampling

rate

1- 99

High

frequency,

modified

sampling

rate

or

255-176

Low

frequency

(See add.

0

High

frequency,

mid-range

sampling

rate

=0: Default motor control with high frequency

(20 / 40 kHz) and an EMF-sampling rate that

automatically adjusts between 200Hz (low

speed) and 50Hz.

Tens digit 1 - 4: Reduced sampling rate com-

pared to default (less noise!)

Tens digit 6 - 9: Increased sampling rate com-

pared to default (one of the steps against buck-

ing!)

Ones digit 1 – 4: EMF sampling time shorter

than default setting (good for coreless motors

for less noise, more power)

Ones digit 5 - 9: EMF sampling time longer

than default (may be needed for 3-pole motors

or similar)

= 255 - 176: Low frequency - PWM according

to formula (131+ mantissa*4) *2exp. Bit 0-4 is

“mantissa”; Bit 5-7 is “exp”. Motor frequency is

the reciprocal of the PWM.