Function-Decoders MX681, MX685, MX686, MX687, MX688 Page 1

INSTRUCTION MANUAL

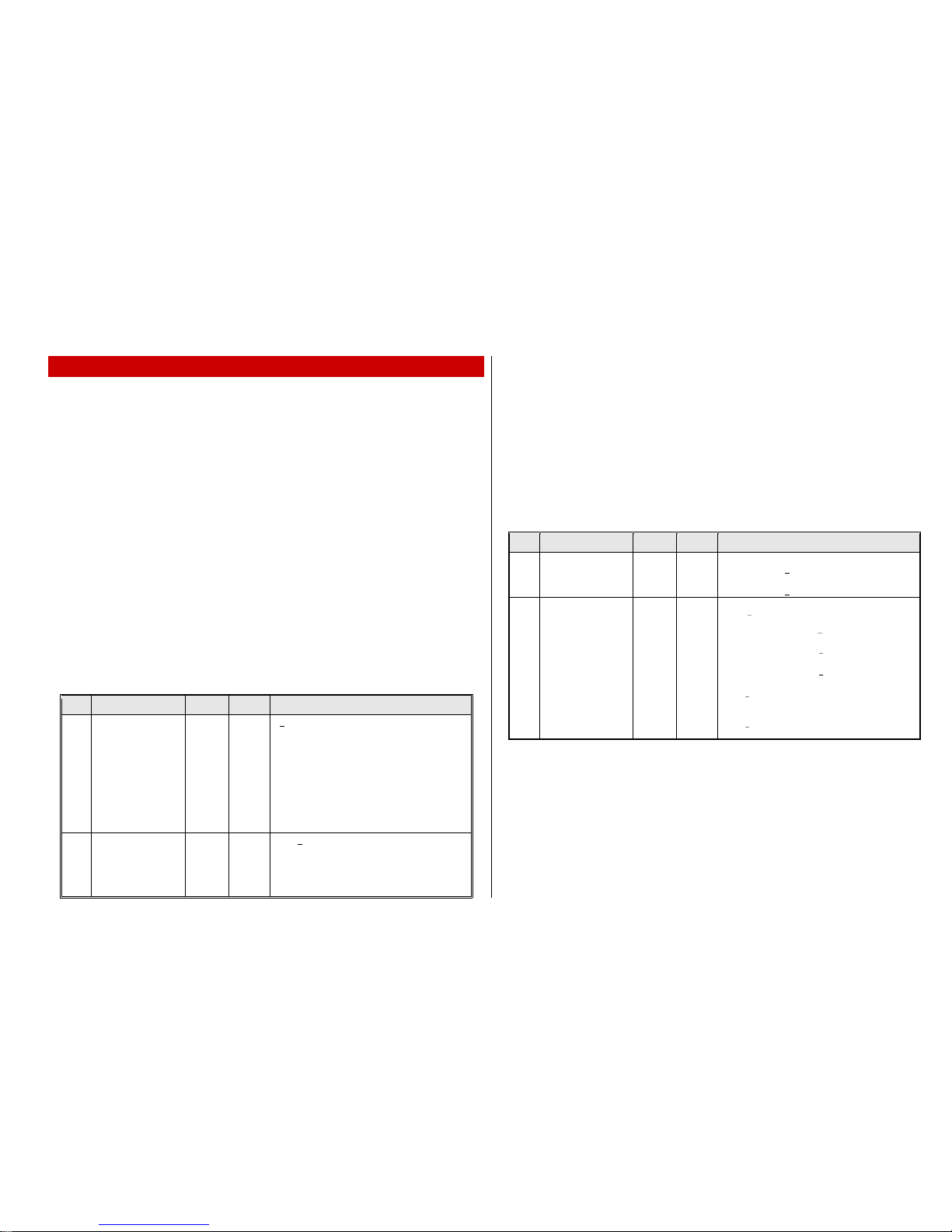

MX681N

MX681

MX685P16

MX685

2

MX686

MX686D

(Design since 2013)

MX689

MINIATURE - FUNCTION - DECODER

MX681, MX681R, MX681N

FUNCTION - DECODER

MX685, MX685R, MX685P16

FUNCTION - DECODER with energy storage circuitry

MX686, MX686D MX688N18

FUNCTION - DECODER with energy storage circuitry and low-voltage output

MX687V, MX687W, MX687WD

FUNCTION - DECODER with NEXT-18 interface

MX688N18

1Overview.................................................................................................................2

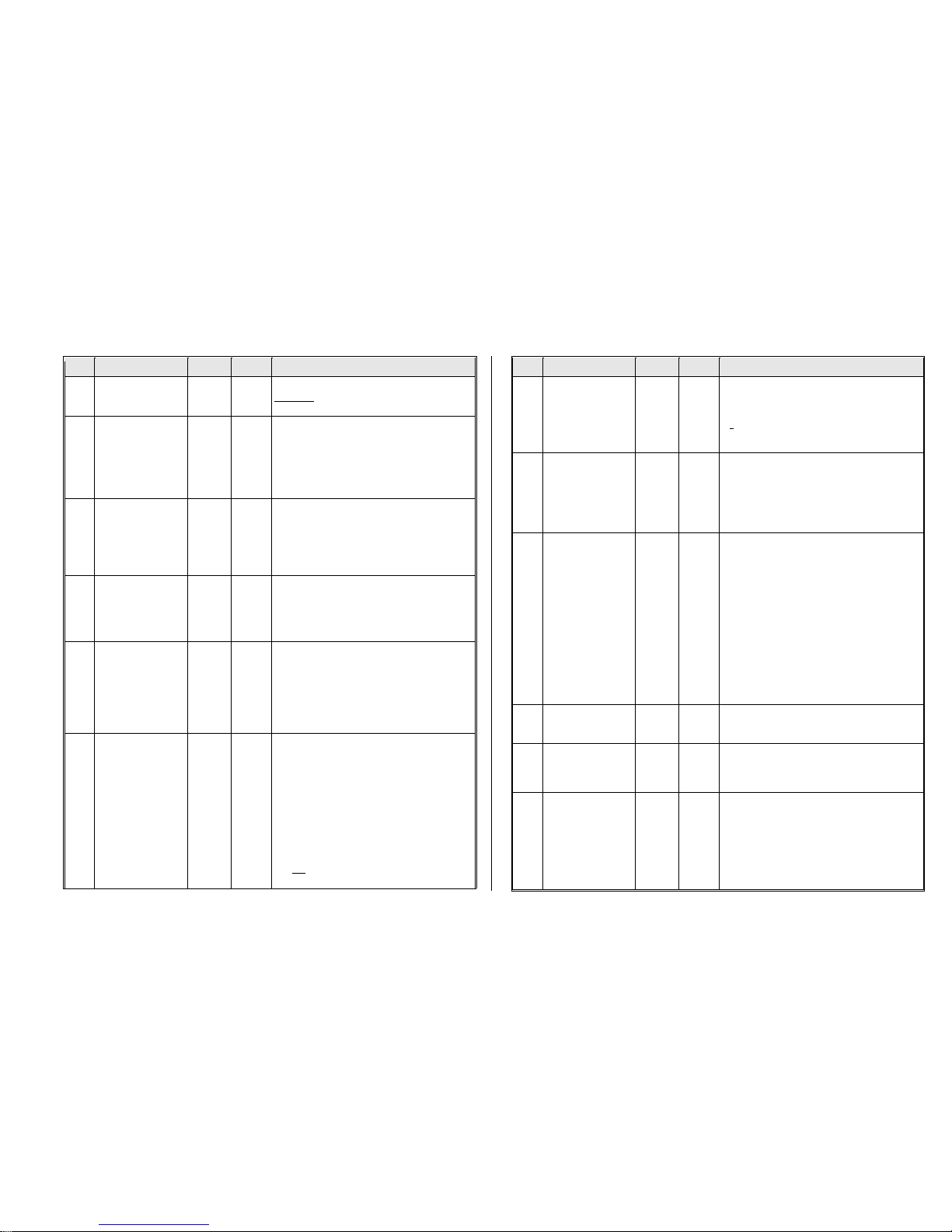

2Technical Information...............................................................................................3

3Adressing and Programming....................................................................................5

3.1 Programming in “Service mode” (on programming track) .........................................................5

3.2 Programming in “Operations mode” (a.k.a. on-the-main, “PoM“) .............................................5

3.3 Decoder-ID, Load -Code, Decoder-Type and SW-Version.......................................................6

3.4 The (first) vehicle address .........................................................................................................6

3.5 The second address in a function decoder ...............................................................................7

3.6 Analog operation........................................................................................................................7

3.7 “Virtual” motor control and momentum ......................................................................................8

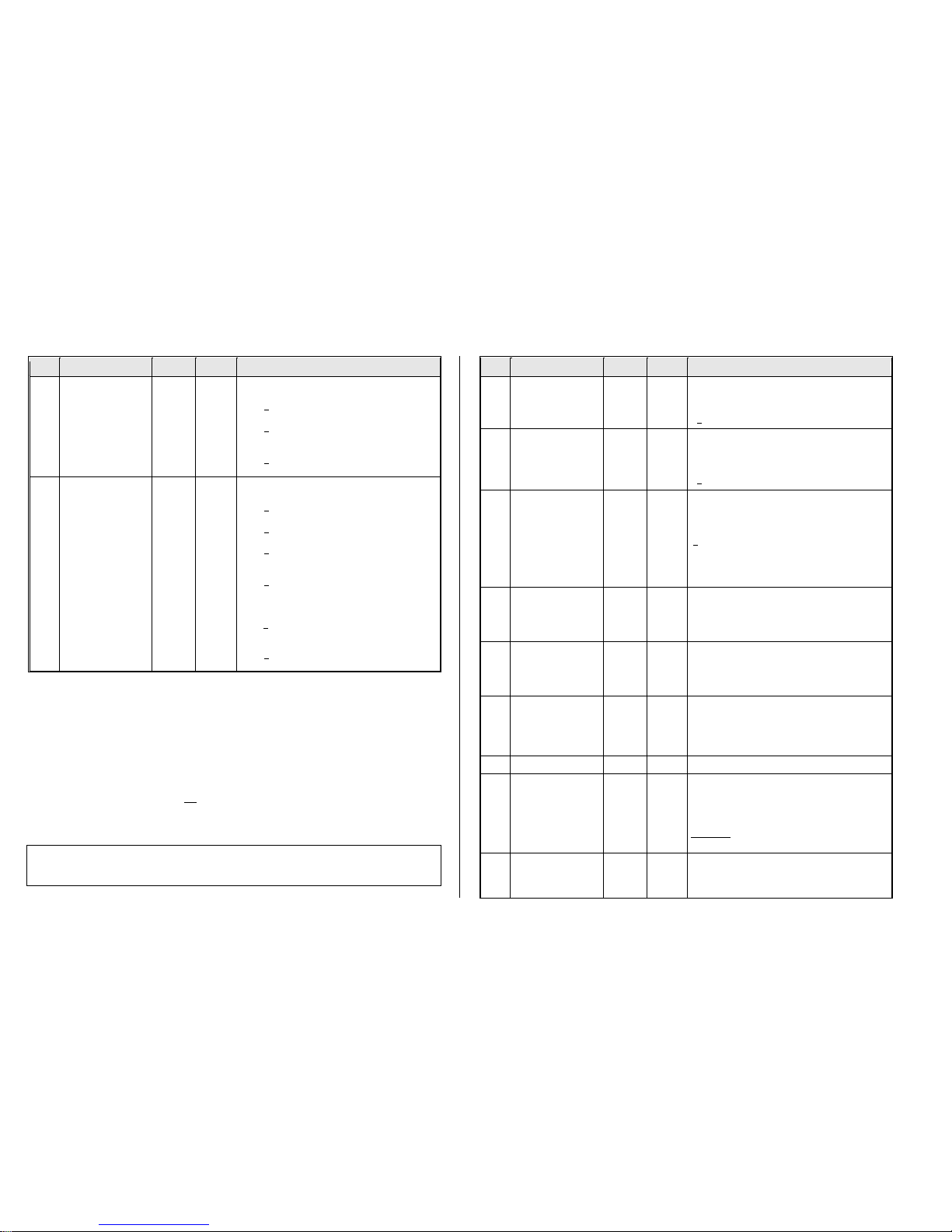

3.8 The NMRA-DCC function mapping .........................................................................................10

3.9 “Unilateral Light Suppression” .................................................................................................11

3.10 The “Swiss Mapping” (SW version 32 and higher)...............................................................11

3.11 Dimming, Low beam and Direction Bits...................................................................................12

3.12 The Flasher Effect....................................................................................................................13

3.13 F1- Pulse Chains (only for old LGB products).........................................................................13

3.14 Special Effects for Function Outputs (US and other lighting effects…) ..................................14

3.15 Configuration of Electric Uncouplers .......................................................................................15

3.16 SUSI-Interface and Logic-Level Output...................................................................................15

3.17 Servo Configuration.................................................................................................................15

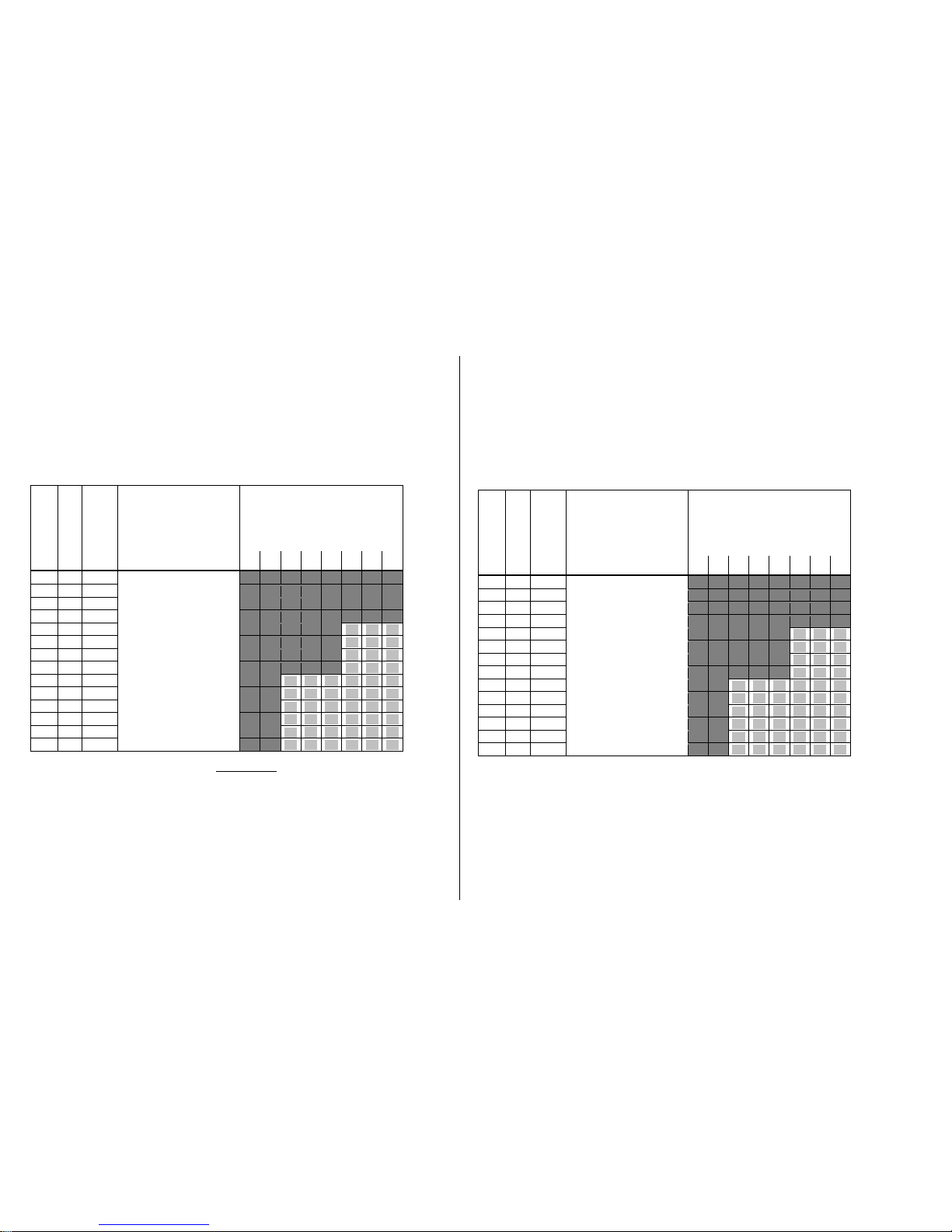

4Feedback - “Bidirectional communication”.............................................................16

5Operating with Märklin MOTOROLA Systems........................................................ 17

6ZIMO Decoder - Software Update.......................................................................... 17

NOTE:

ZIMO decoders contain anEEPROM which stores software that determines its characteristics and functions. The software version can be read out form CV #7 and

#65. The current version may not yet be capable of all the functionsmentioned in this manual. As with other computer programs, it is also not possible for the

manufacturer to thoroughly test this software with all the numerous possible applications. Installing new software versions later can add new functions or correct

recognized errors. SW updates can be done by the end user for all ZIMO decoders since production date October 2004, see chapter “Software Update”! Software

updates are available at no charge if performed by the end user (except for the purchase of a programming module); Updates and/or upgradesperformed by ZIMO

are not considered a warranty repair and are at the expense of the customer. The warranty covers hardware damage exclusively, provided such damage is not

caused by the user or other equipment connected to the decoder. For update versions, see www.zimo.at.