Chapter 1: Introduction

ZP3-ECU Extinguishing Control Unit User Guide 3

ZP3-ECU control unit overview

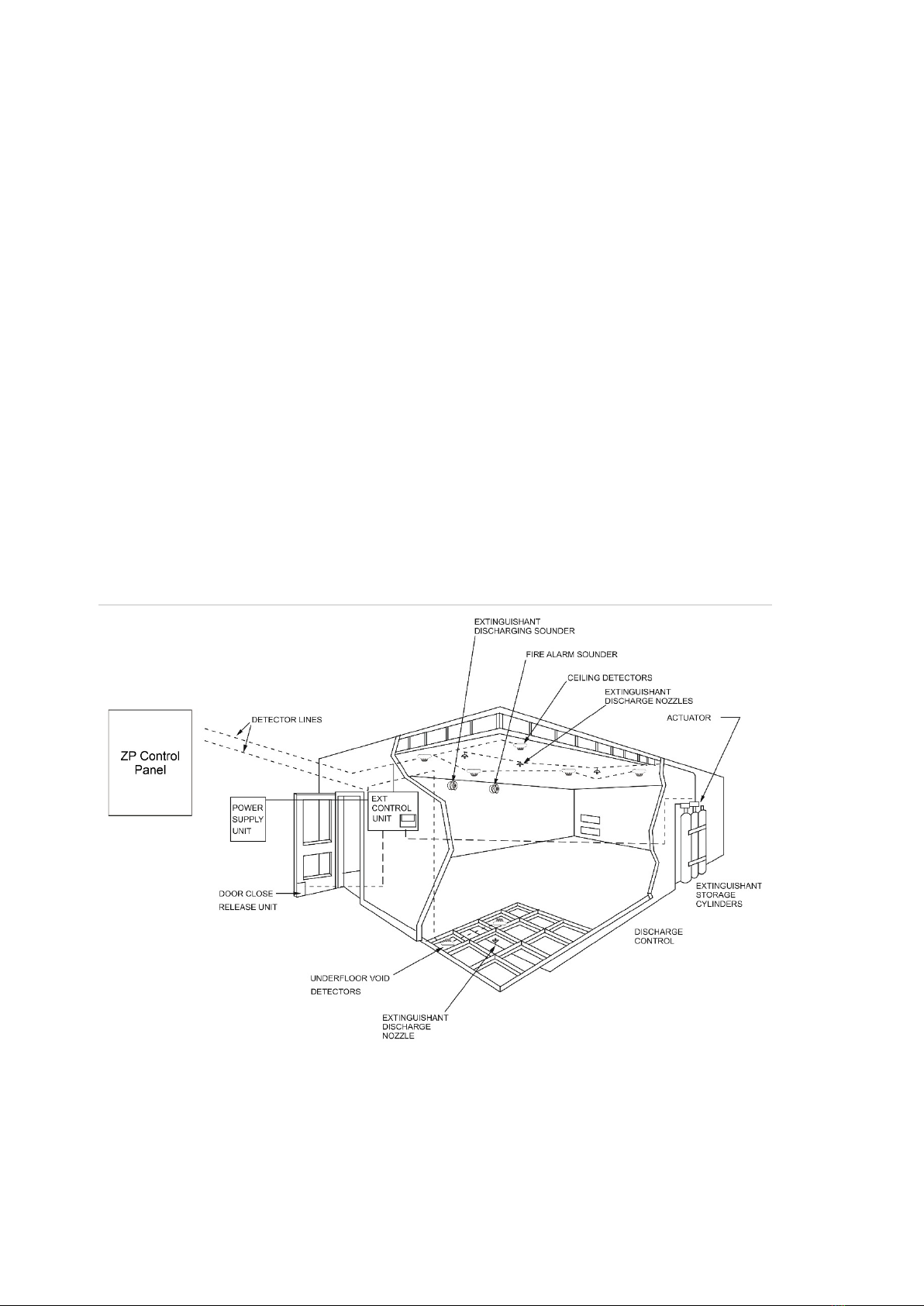

The ZP3-ECU Extinguishing Control Unit (Figure 2 on page 4) is designed to

connect to a Ziton addressable fire alarm detection system and control a fire

extinguishing system. It interfaces to the fire detectors of the fire detection

system and provides secure "coincidence connection" control of the

extinguishing system.

The self-contained unit has key switches for automatic or manual selection, as

well as lock-off for maintenance. Other controls are a manual extinguishant

release, an alarm silence button, extinguishant hold off button and indicators for

automatic, manual, locked-off, fault, fire, extinguishant discharged, and reset

status.

Outputs are provided for extinguishant release valves or actuators, audible fire

alarm sounders, separate extinguishant release sounders, visual exit signs, door

closing, and shutter release. Also provided are facilities for remote manual

extinguishant release, and remote operation and status functions.

Extensive monitoring is provided for many functions, including power supply,

fuses, and operation. Field wiring is monitored for extinguishant release

valves/actuators, fire sounder, extinguishant sounder, and manual extinguishant

release units.

Optional monitoring is provided for low extinguishant pressure, extinguishant

release verification, and locked/unlocked entry door status of the protected area.

The ECU is under the control of the fire alarm control panel. It communicates

with the fire alarm control panel every two seconds and reports the status of all

functions. A fault signal is raised at the fire alarm control panel for any out-of-

normal condition, which exists at the ECU. The fire alarm control panel indicates

the type of fault, and where applicable, reports the condition to a building

management system. Remote status of each ECU – automatic, manual, fault,

locked-off, or extinguishant discharged can be displayed at the fire alarm control

panel without additional wiring.

Each ECU operates one fire extinguishing system. Any number of ECUs may be

used, with each unit requiring two system addresses. The system is field

programmable, with functions such as detector cross-mapping, automatic

extinguishant release delay, selection of delay/no delay for manual extinguishant

release, and output relay control being fully configurable.