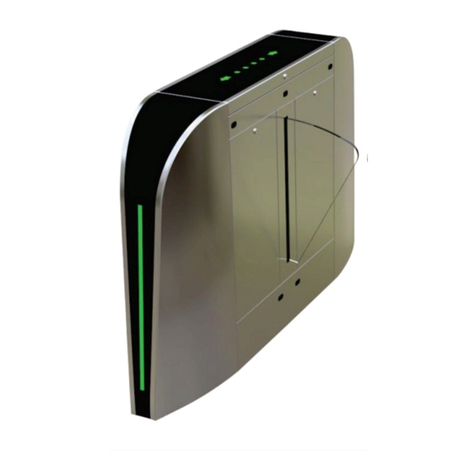

1.5 The working principle of swing barrier

1.5.1 After powered on, the system performs self-check. If no failure is detected, the machine starts to

operate normally. If a failure is detected, the system displays related messages on the LCD Display

screen so that the user can have a quick knowledge of and solve the problem.

1.5.2 When the reader detects a valid card, the buzzer will give a nice audible prompt to the pedestrian,

indicating that the card is being read successfully. And then, the reader sends signals to the access

controller to request permission to pass through the passage.The access controller will send the signal to

the master control panel.

1.5.3 After receiving the signal from the access controller, the master control panel sends valid control

signals to the direction indicator and the electric motor. And the direction arrow turns green.

1.5.4 Pedestrians pass through the channel according to the direction indicator signs, infrared sensors

detect the pedestrians pass through the whole process, and continue to send signal to the master control

board until the pedestrian has been completely through the channel.

1.5.5 If the pedestrian enters the channel but forgets to have the card read by the reader, or the card held

by the pedestrian is invalid, that the system will stop the pedestrian , and give an audible alarm until the

pedestrian retreats from the channel. The pedestrian can pass through the channel only after a valid card

is read by the card reader.

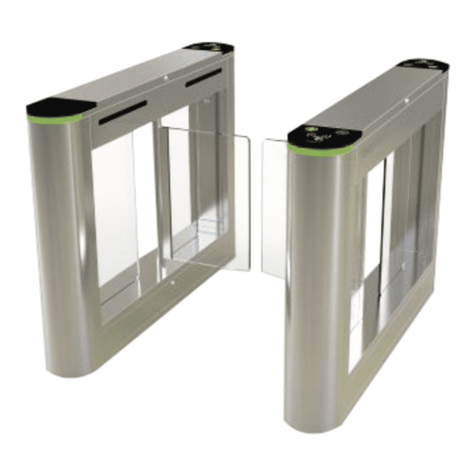

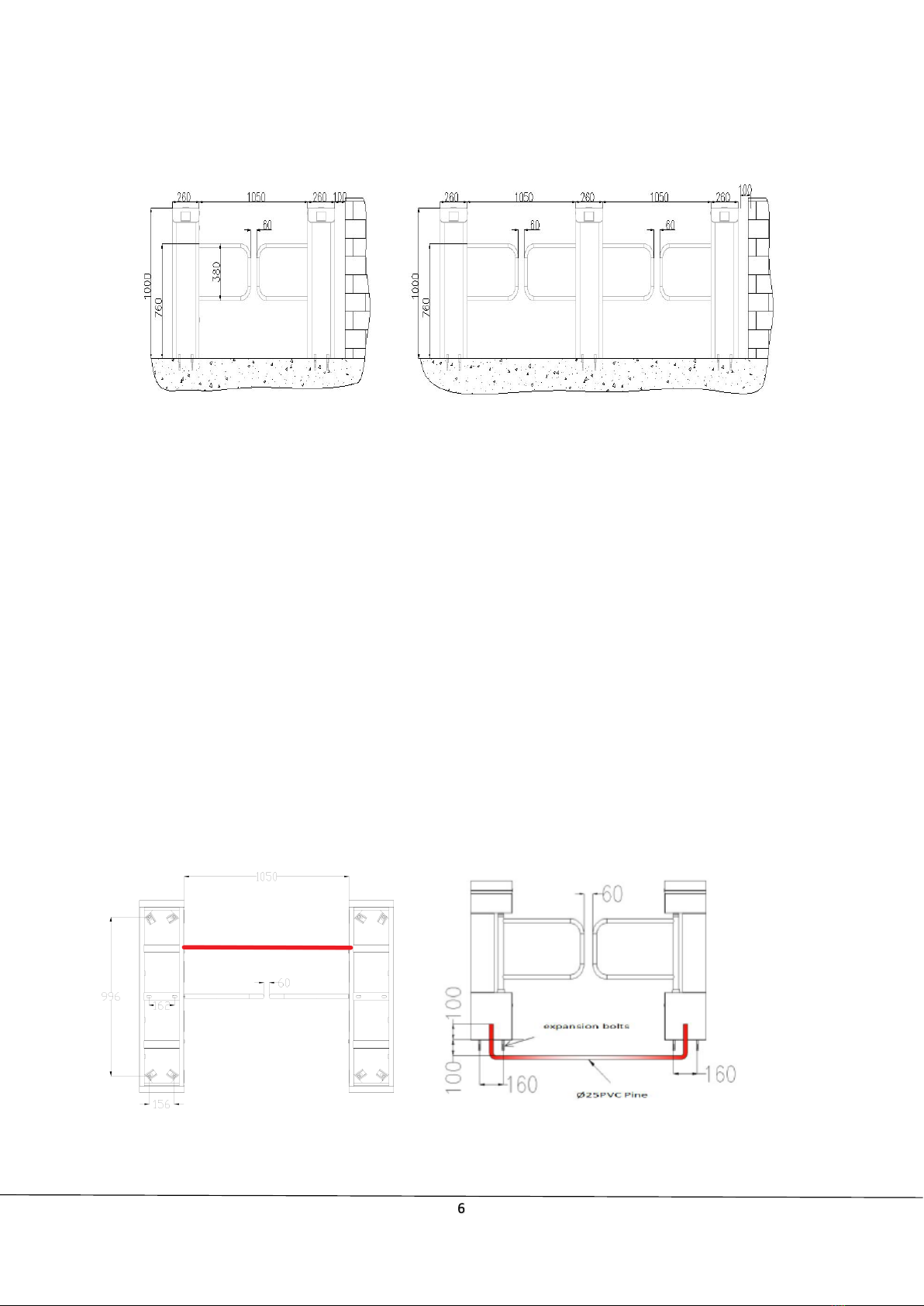

1.6 System composition of the product

The single-channel management system is composed of two single-core swing barrier turnstiles.The

mufti-channel management system is composed of two single-core barriers and multiple dual-core

barriers.

1.6.1 Working modes of the system

To meet the requirements for use for different places, this system provides multiple working modes for the

user.Including fire protection mode, normal working mode, testing mode,. The parameters can be set by

using three built-in keypads ("ENT", "UP", and "DOWN") on the master control panel.

Option 16 in the menu is configurable using the values 0, 1, and 2.

If 0 is used, the system is being under the normal mode and does not detect the fire protection signals.

If the detected fire protection signal is a pulse signal, the value is set to 1. Once this pulse signal is