SBTL300 Series

User Manual

P a g e | 5

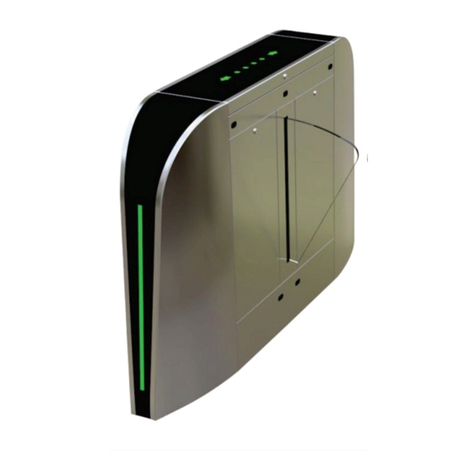

Mechanical System of the Swing Barrier

The mechanical system of a swing barrier turnstile includes the chassis and the core component. The

chassis is a carrier where the direction indicator, the reader, the Infrared sensor, and the door lock

are installed. The core component mainly consists of the motor, the frame, the belt, and the swing

arm.

Electronic Control System

The electronic control system of a swing barrier turnstile is mainly composed of the reader, the

master control panel, the infrared sensor, the direction indicator and the alarm.

Reader (optional): The reader reads the data in the card and sends it to the controller.

Master control panel: The master control panel is the system’s control center that receives signals

from the reader and the photoelectric switch, performs logical judgment and processing of these

signals, and sends executive commands to the direction indicator, the electric motor and the alarm.

Infrared sensor: It detects the position of a pedestrian and plays the role of safety protection.

Direction indicator: This indicator displays the pedestrian passage path, and directs them to pass

through the lane in a safe and orderly manner.

Alarm: The alarm gives an alarm voice if the system detects any unauthorized entry to the lane.

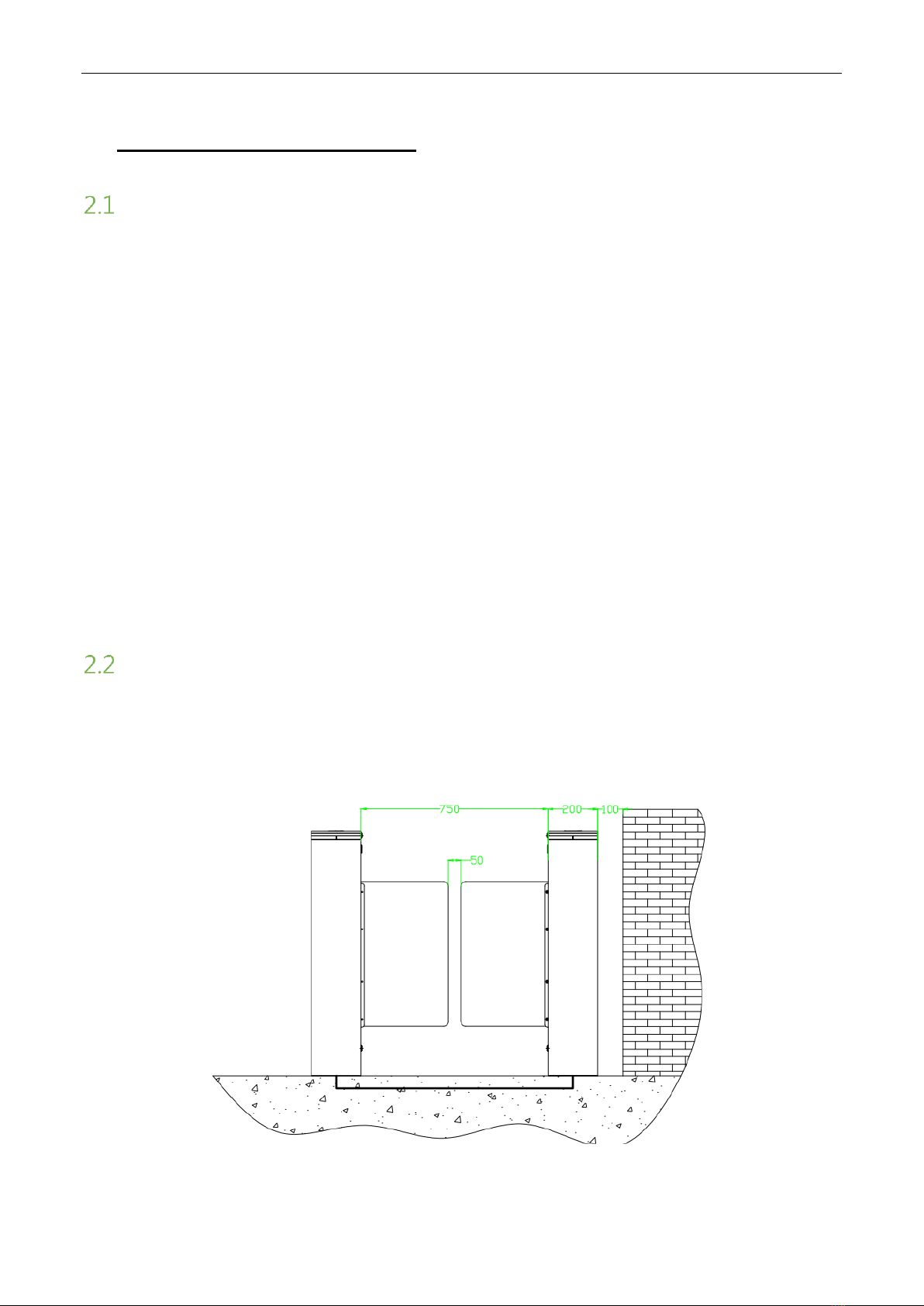

System Composition of the Product

The single-lane management system is composed of two single-core swing barriers. The multi-lane

management system is composed of two single-core barriers and multiple dual-core barriers.

Working modes of the system

To make the product more versatile, this system provides multiple working modes for the user,

including normal working mode, normally open and normally close mode, testing mode. After

supplying power to the device, the digital screen on control board will display a default state, which

displays current work mode.

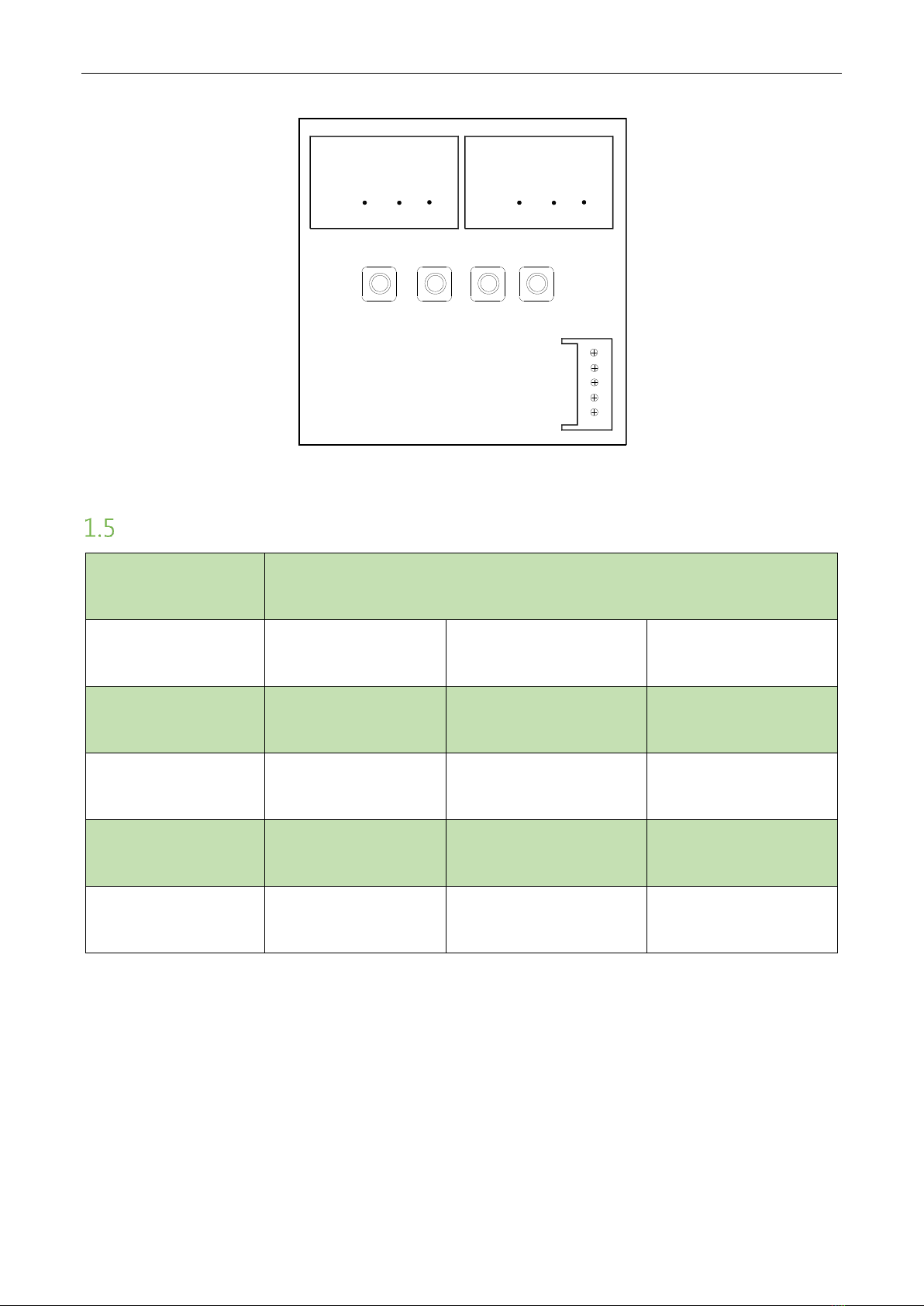

There are 4 operation buttons on the keypad, "MENU", "MODE", "ADD" and "DEC". (Figure 1-2)