!!!

!!!

!!!

!!!

!!!

!!!

!!!

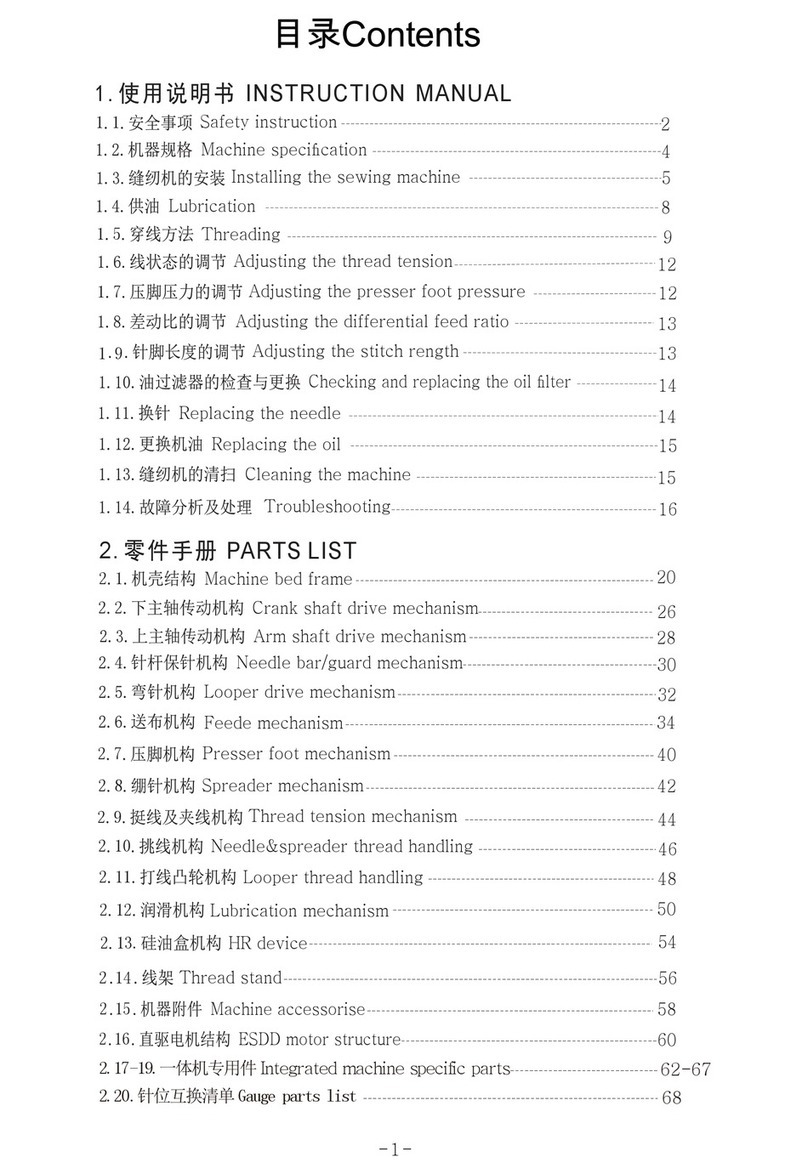

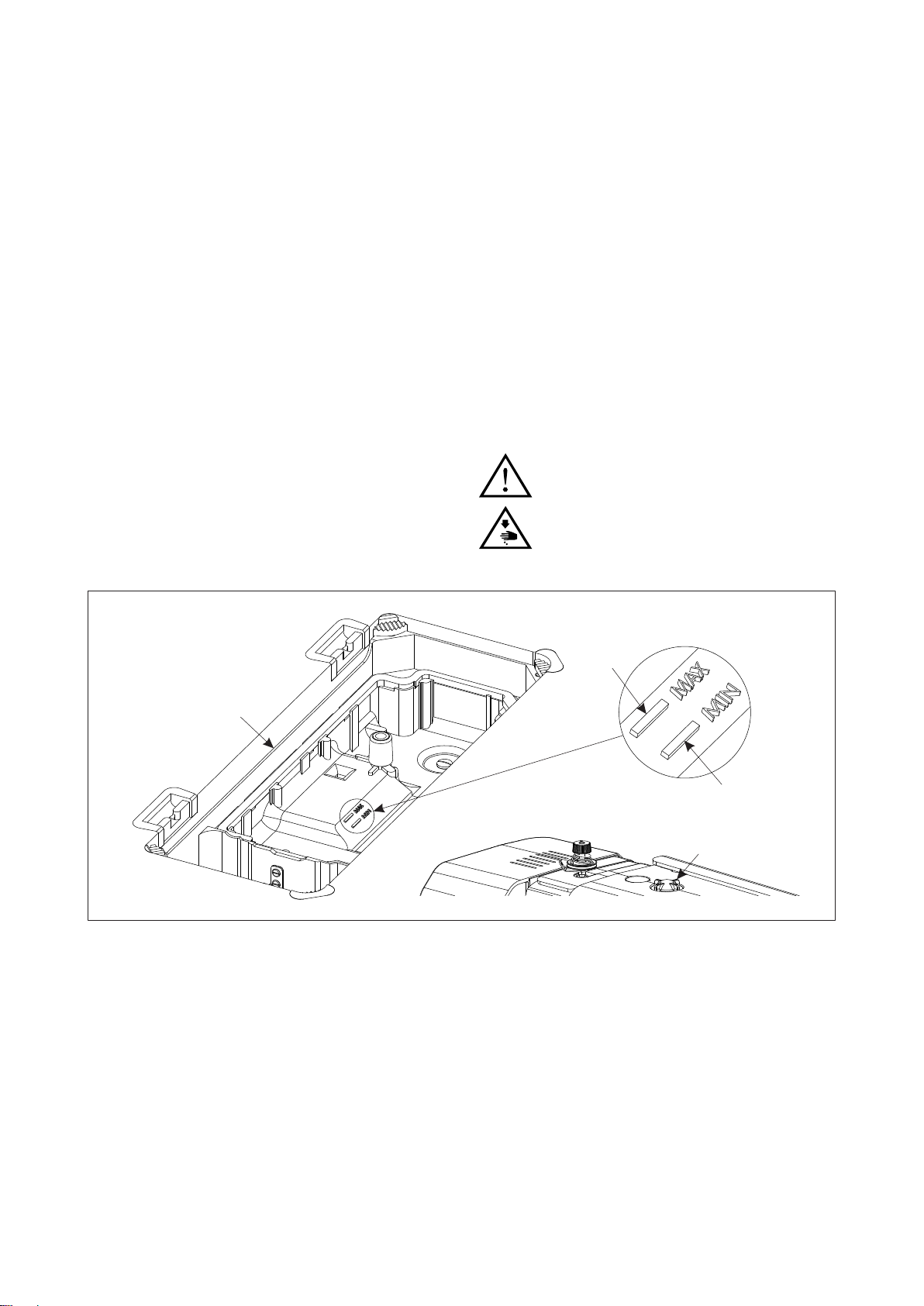

Be careful

Sewing

This sewing machine is only used by persons trained in safe

operation.

This sewing machine cannot be used for any purpose other

than sewing.

Protective glasses must be worn when sewing machines are

used.

If you don't wear protective glasses, there will be danger

when you break the needle. The broken part of the needle

may pop into your eyes and cause injury.

When the following happens, please cut off the power

supply. Otherwise, when you step on the pedal, the sewing

machine will cause injury.

·When the needle goes through the thread

·When changing needle or shuttle core

·When a sewing machine is not in use or when a person

leaves the sewing machine

If a worktable with casters is used, the casters should be

fixed so that they cannot move.

For the sake of completeness, please install protective

device before using this sewing machine. If these safety

devices are not installed, use sewing opportunities to cause

personal injury and sewing machine damage.

During the sewing process, do not touch any moving parts

or place the objects on the moving parts, because this will

cause injuries to people or damage to the sewing

machine.

When the head of the sewing machine falls down, please

make sure that the worktable is fixed and not moved at

will. Accidents such as foot clamping have occurred in the

move -ment of worktable, which is the cause of personal

accidents.

When the sewing machine head falls down or stands up,

please operate with both hands.

One-handed operation can easily cause injury if the

weight of the sewing machine slips.

If the sewing machine operates incorrectly, or hears

abnormal noise or smells abnormal odor, the power

supply should b e cut off immediately. Then contact the

shop or trained technicians.

If the sewing machine breaks down, please contact the

shop or trained technicians.

Clean

Please cut off the power supply before starting the cleaning

operation.

If you step on the pedal by mistake, the sewing machine will

cause injury.

When the head of the sewing machine falls down, please

make sure that the worktable is fixed and not moved at will.

Accidents such as foot clamping have occurred in the

movement of worktable, which is the cause of personal

accidents. When the sewing machine head falls down or

stands up, please operate with both hands.

One-handed operation can easily cause injury if the weight

of the sewing machine slips.

When lubricating oil and butter are used, it is necessary to

wear protective glasses and gloves to prevent lubricating

oil from falling into serious or sticking to the skin, which is

the cause of inflammation.

In addition, lubricants or butter should not be drunk,

otherwise vomiting and diarrhea will occur.

Keep oil out of reach of children

Maintenance And Inspection

When the head of the sewing machine falls down, please

make sure that the worktable is fixed and not moved at

will. Accidents such as foot clamping have occurred in the

movement of worktable, which is the cause of personal

accidents. When the sewing machine head falls down or

stands up, please operate with both hands.

One-handed operation can easily cause injury if the weight

of the sewing machine slips.When replacing parts or

installing optional accessories, be sure to use only

genuine parts.

The Company will not be liable for any accident or

malfunction caused by the use of non-authentic parts.

When removing the safety protection device and installing

it again, be sure to install it in situ and check whether it

can work properly.

In order to prevent accidents and malfunctions, please do

not alter the sewing machine without authorization.

The Company will not be liable for any accident or

malfunction caused by the modification of the sewing

machine.

Only trained technicians can repair, maintain and inspect

sewing machines.

All works linked with ellectricity should be entrusted to

purchasing shops or electrical professionals.

Turn off the power supply when the following happens. Pull

the plug from the power outlet.

Otherwise, when you step on the pedal, the sewing

machine will cause injury.

Maintenance, maintenance and inspection related to electric

Inspection, adjustment and maintenance

Replacement of fragile parts such as spindle and cutter

Before opening the motor cover, be sure to turn off the

power supply, wait a minute, and then perform the

operation. Touching the motor surface can cause burns.

When the power switch must be connected to adjust, be

sure to switch to maintenance mode.

Be careful to observe all safety precautions