IN

S

TRUCTION

MANUAL

FOR

POS

T-

BED

IN

DUSTRIAL

S

EWING

MACH

I

NE

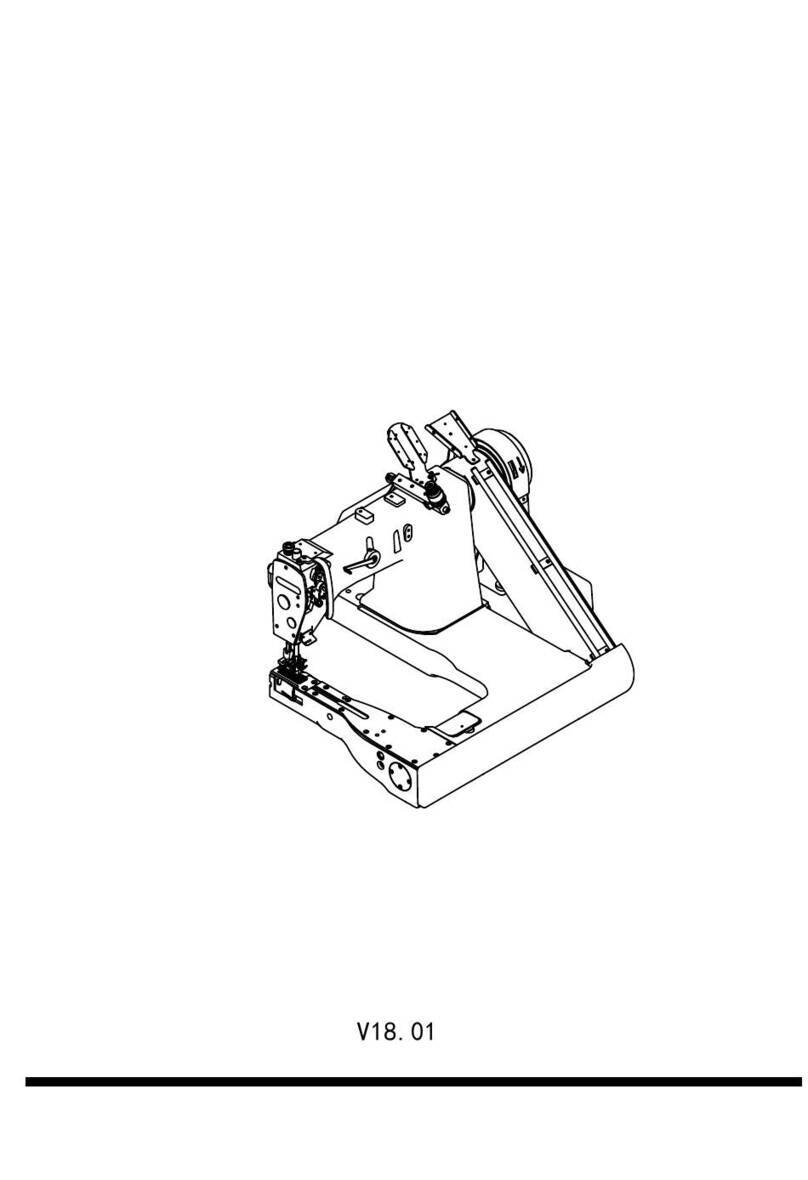

This manual is prepared to permit the sewing machine to be

used

efficiently and for highest performance.

This machine is

post

-

bed

industrial sewing machine suitab

le

for sewing sboes,bags,capsandgeneral

leather works.

You

caneither select

1-n

.eedleor2-oeedle machine accordi

og

to your

type

of

works.

Being

eq

uipped withspring

return

reverse lever

rype

feed mechanism opener

type

vertical hook, and slide

type thread take-up provides perfect

uoif

omed

stitching.

- i

NDEX-

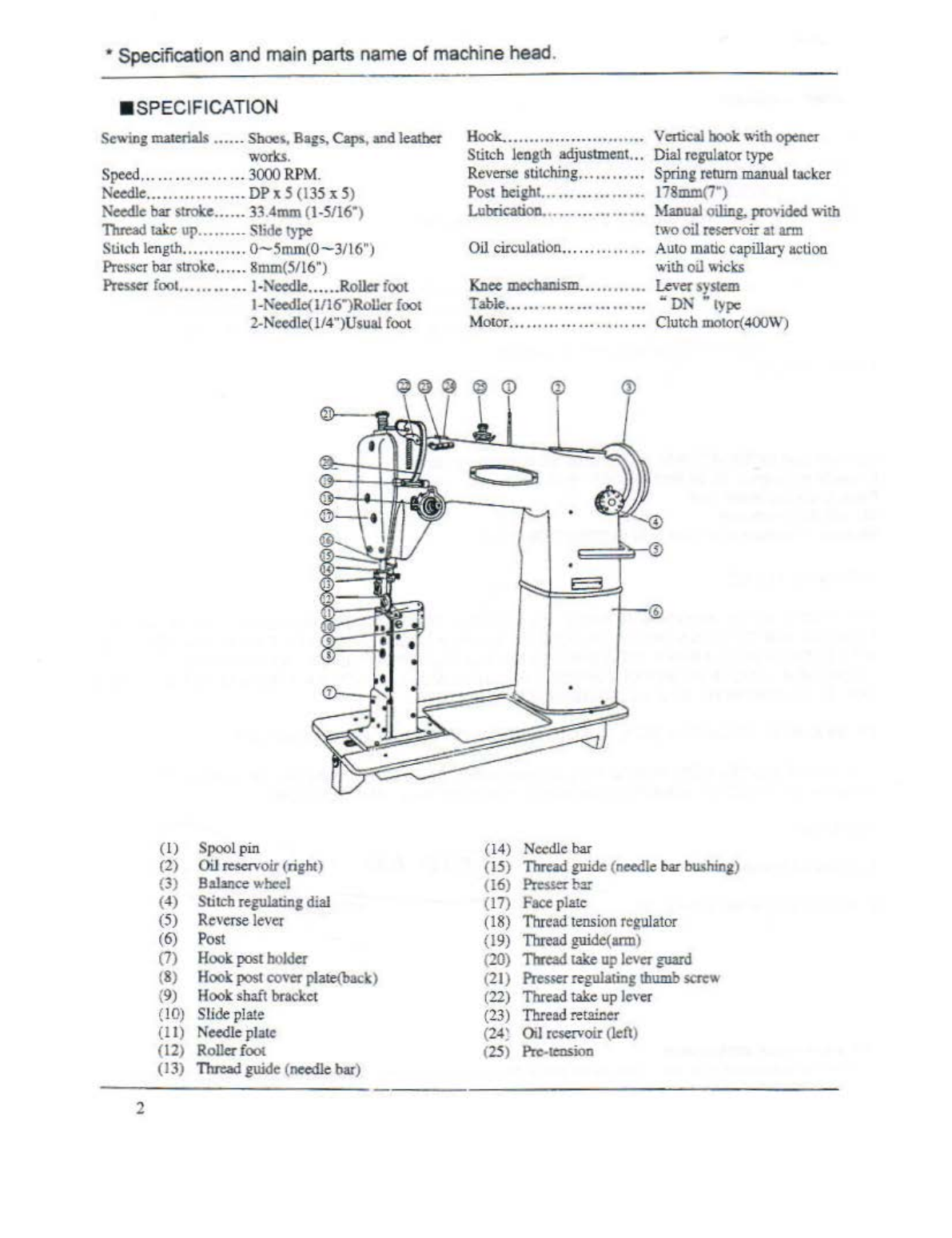

Specification

........

..

.........

.....

.................

.

.................................................................

.2

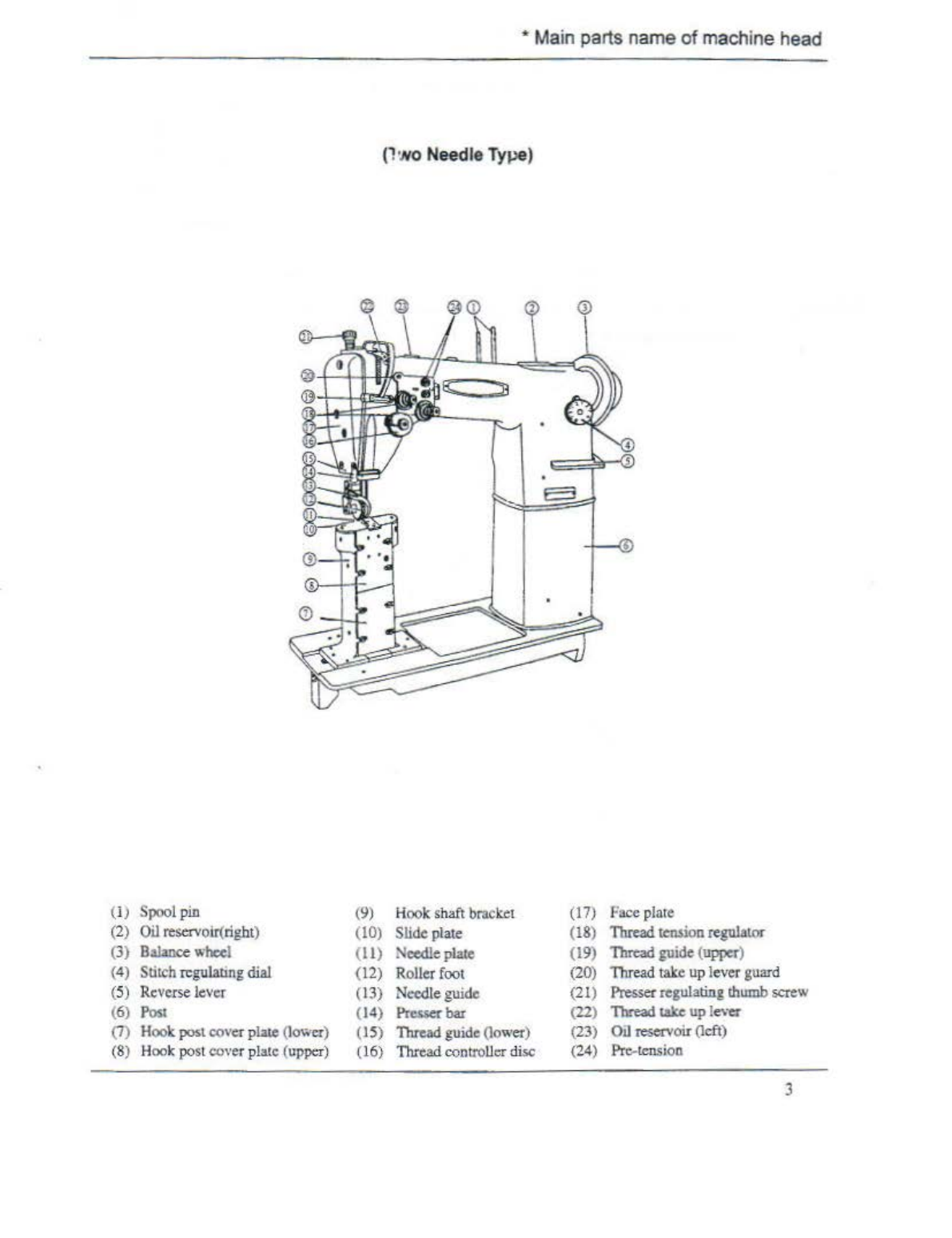

Main

parts

name

of

ma

c

hine

head

.................

.

..............................

..

...................

.

...........

3

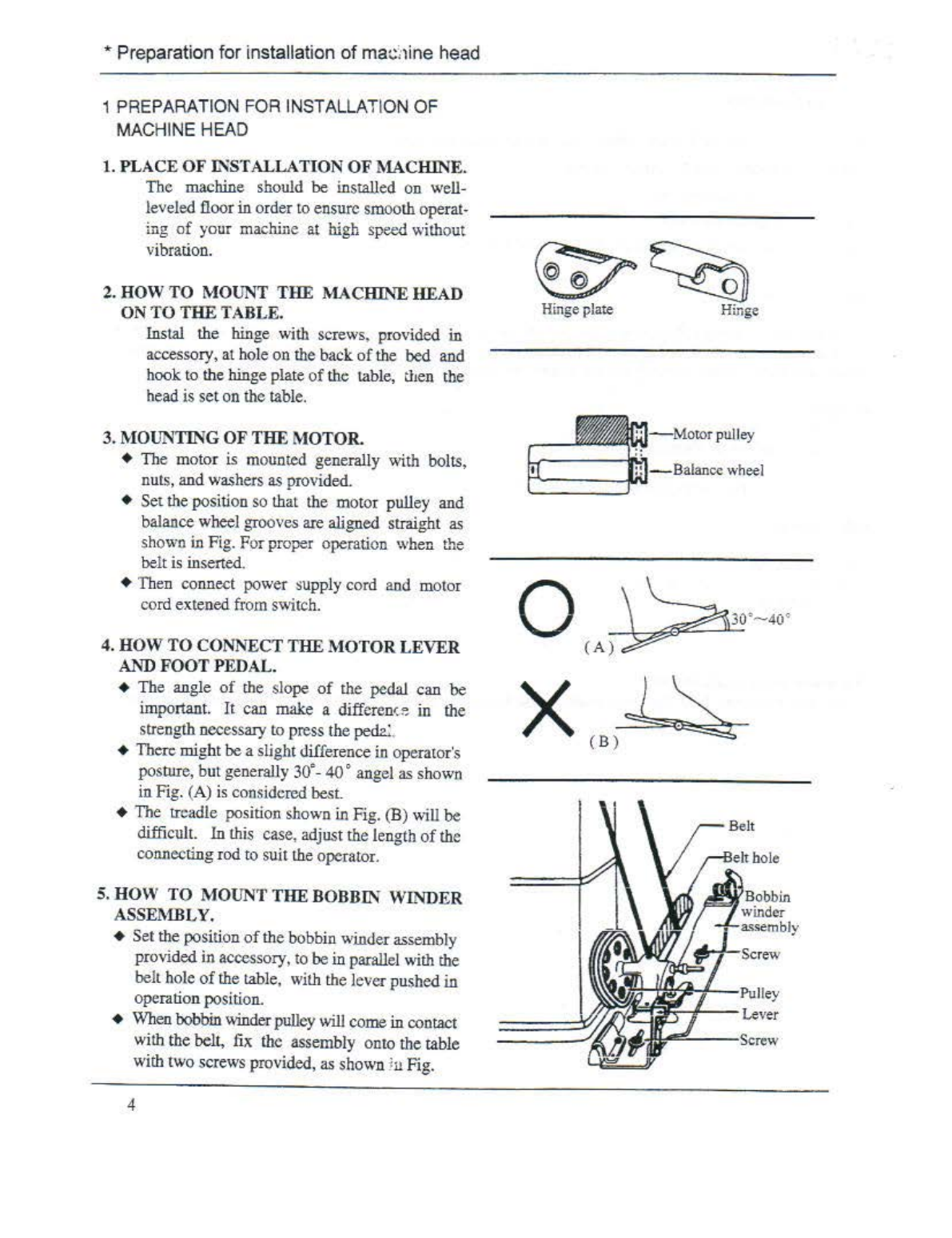

L Preparation f

or

installation

of

machin

e

................

..

..........

.....

......

.

...............................

.4

1).

Place

of

installation

of

machine

..................

..

....................

.

........

,

...............................

4

2)

.How

to

mount the machine head

..

.

....•....

....

......

...

..

..

.......

..

...

,

......

.

.............

.

........

.

..

.

...

..

.4

3).

How

to

mount the motor..

.........

.

.........

..

..............

.

...........

.

...........

.......

.....................

.4

4). How

to

COillleet

the

motor

leverand

foot

pedal.••.•..•

.............•.

•••••.•.•.•.•.•..

.......•

••.•.•••••••...4

5). How to

moun

t the bobbin winder assembly

....

..

....

...

.....

...

....

.........

...

.......

..

............

..

....

.

.4

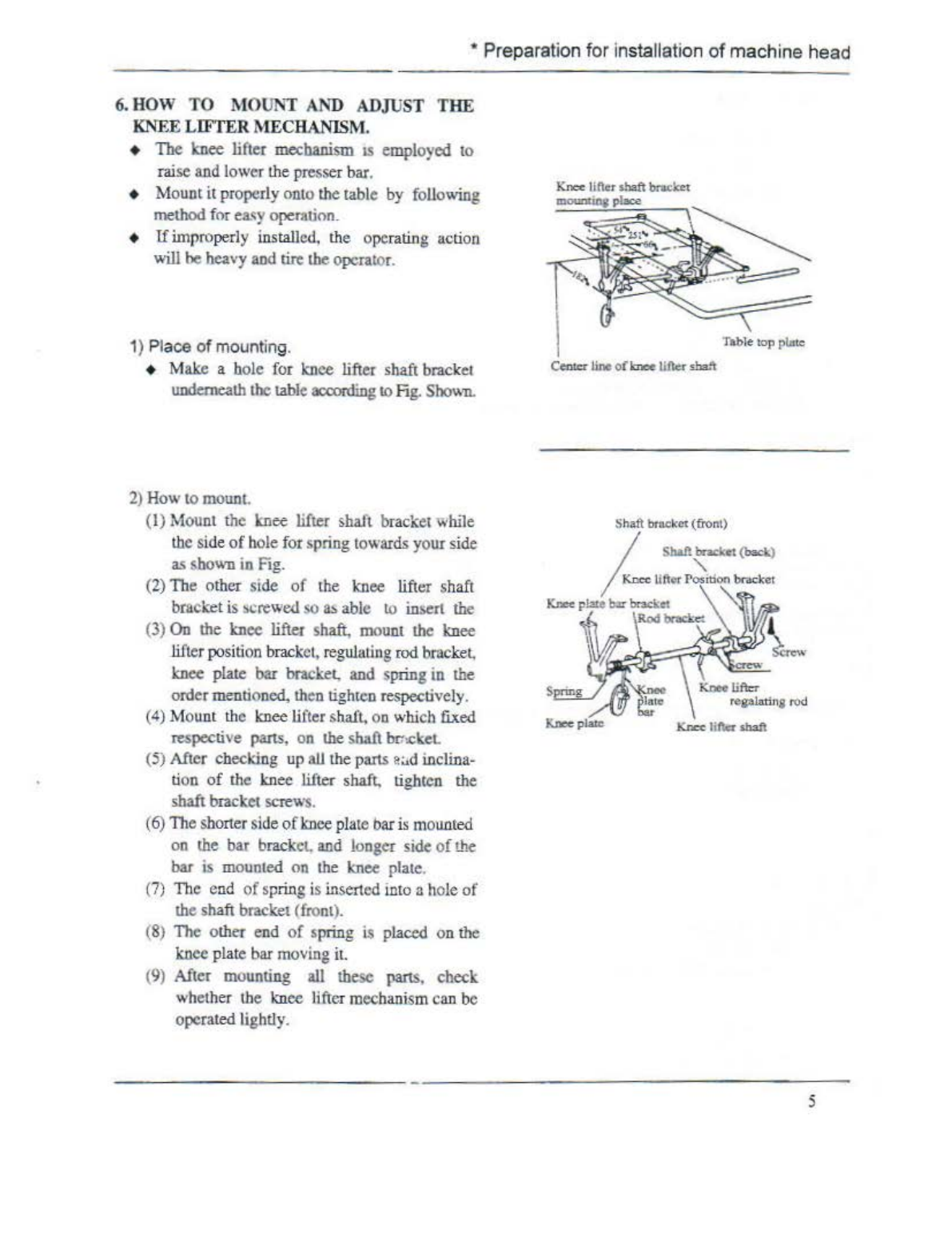

6).

!l

ow

to

mount

and

adjust

th

e knee lifter mechanism

..

.....

....

.........

...

..

.

...

....

.........

.....

...

......

.5

7).

How

to

mount

the

oil

pan.

..

...............................

.

..........

.

.....................

.

....•......

.

..........

6

8). How to mount the vibration

preventi.r.~

rubber

..

...

....

..

........

...

.........

..

.....

.

..

...

.......

..

..........

6

U.

Pr

eparation f

or

operation

..........................................................

.

...............................

7

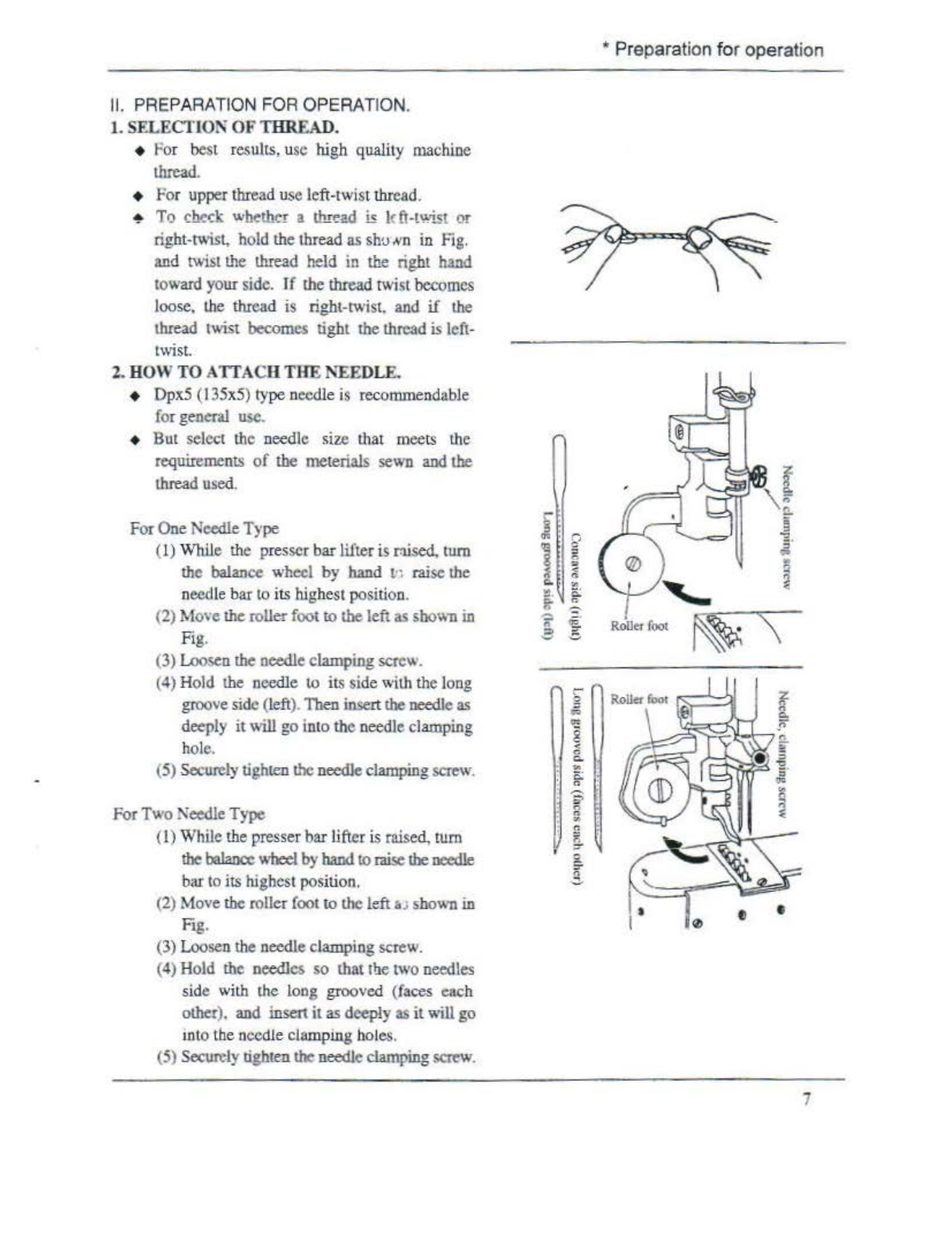

I). Selection

of

thread

....

.

.........

...

.

..........

...

....

..

...

...

......

.........

....

........

....

.....

.

....

...

.....

7

2). How

to

attach the

oc

:edle

............

......

...

.......

..

..

.....

.

.......

....

...

...

......

..

..

..................

.7

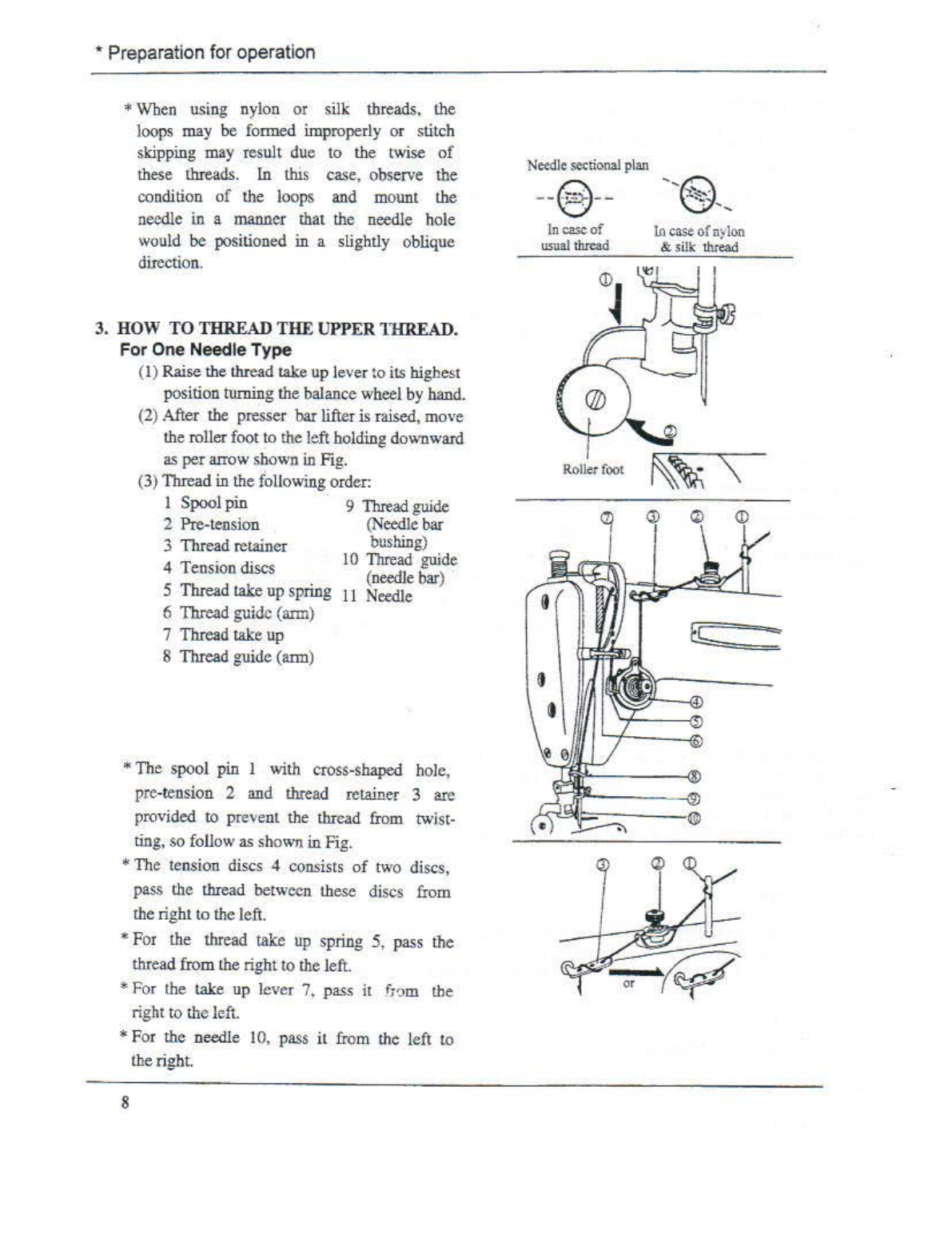

3

).

How

to

lead the upper thread

........

.

.....

.......

................

.......

.....

.....

...............

...

.........

8

4

).

How to wind

the

lower thread on the bobbin

..

.

......

.

................................

..

......

....

.

..

......

9

5).

How to adjust the bobbin winder asscmbly

...

..:

.........

....

............

.

.......

.

.......................

IO

6)

.

How

to place

the

bobbin into the hook

.....

...

...................

........

...............

.

...................

11

m.

Bow

to operate

.....

.......

...

....

......

.........

....

..

....

,

.......

...

..

.........

......

.......

.

......

..

..........

.

l3

1).

Starting

to

sewing

.................

...............

....

.......

.....

.....

........................................

13

2).

Sewing over

........

.

......

...

.........

...

................

.

......................

.........

..........

.

......

....

13

IV. Stitching adjustment

....

.....

...

......................

...............

........

............................

......

..

14

1

).

Adjustment

of

stitch length

.................

..

....................

..

...................

..

...........

..

......

14

2).

Forward and Reversestitching

....

.

...

........

....

.....

.......

.................

.....

.........

..

....

........

14

3).

Adjustment

of

thread !etlsion

...

...

........................................................................

!4

4). Adjustment

of{ccd

dog height and pressure of

pre.sse;-

on

materials

..............

.

..................

17

5). Propef ti

ming

between

th

e hook

and

needle.

......

...

..............

....

...

..

........

....

...

...

....

.

....

...

18

6). Proper timing between the book and opener

..........

.

...................................

..

.....

....

......

21

7). Proper timing between the

feed

dog

and

needle

...

....

..................................................

22

V.

Cleaning

and

Lubrication

.....................

...

.................

.

.............................................

23

1).

Oeaning

...........................

..

.................

.

................................................

..

........

23

2).

Lub

rication

...

....

...................

.....

.............

..

.....

.

.................................

,..,

.......

......

23

3).

Gr

ease

.

...............

.........

.....

..........

........

....

......

..................

...................

.....

....

....

24

From the library of: Superior Sewing Machine & Supply LLC