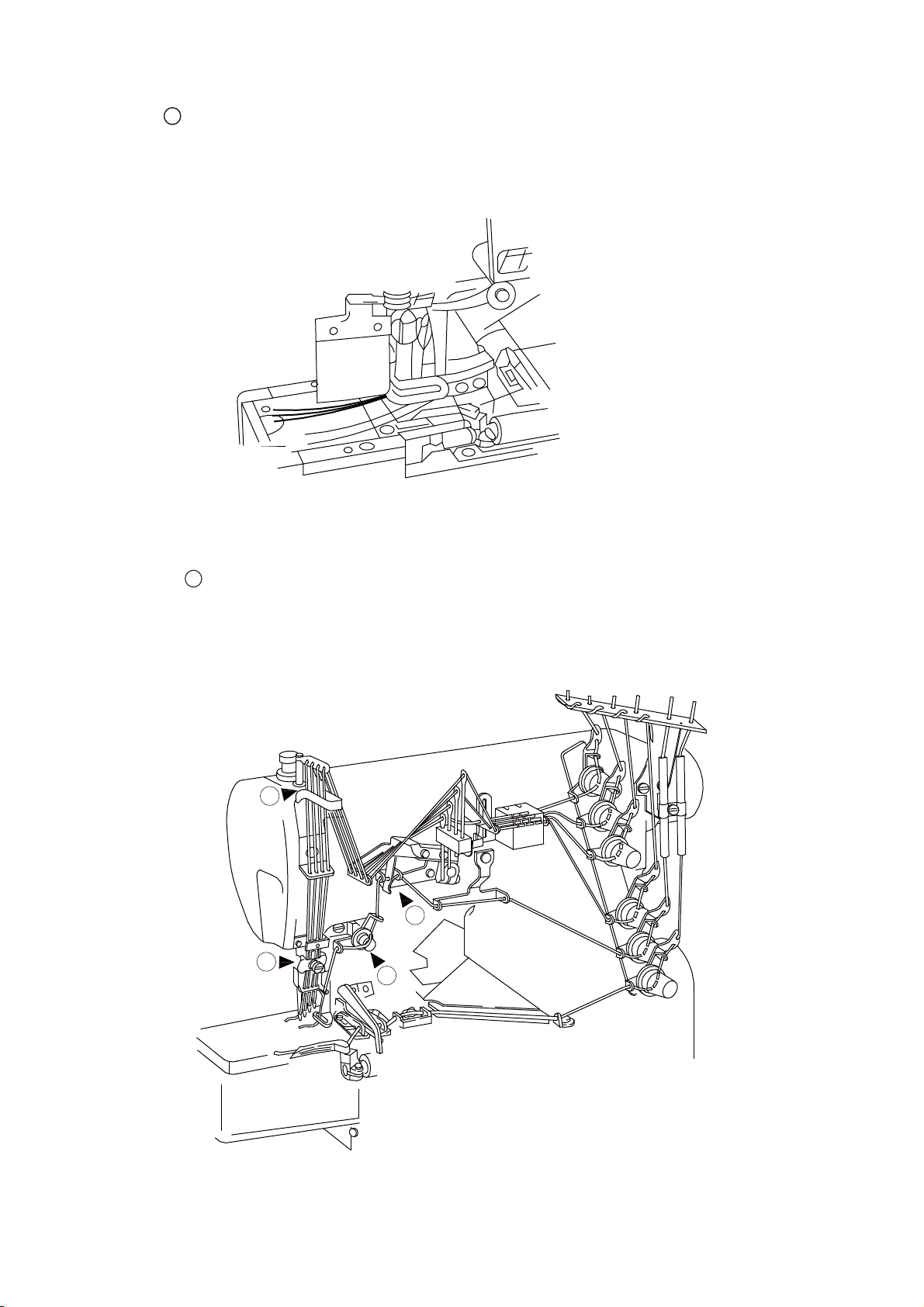

1.1. Safety Instructions( )

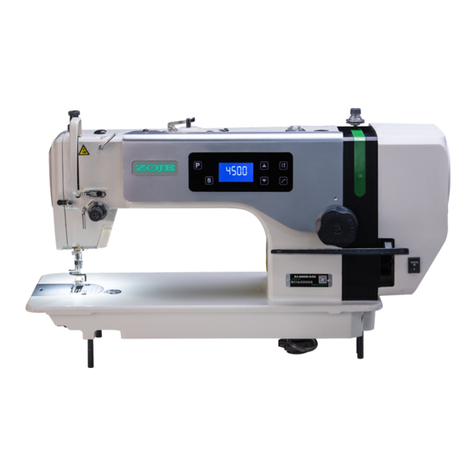

to assure that machine and operator are able to perform the task.

Before starting the machine in full running, a test must be conducted

seek medical

help immediately.

plenty oficy water with

a generous amount of cold water.

In case o ngestionfi

In case oflubricant oil contact with

the eyes or skin, washed the surface with

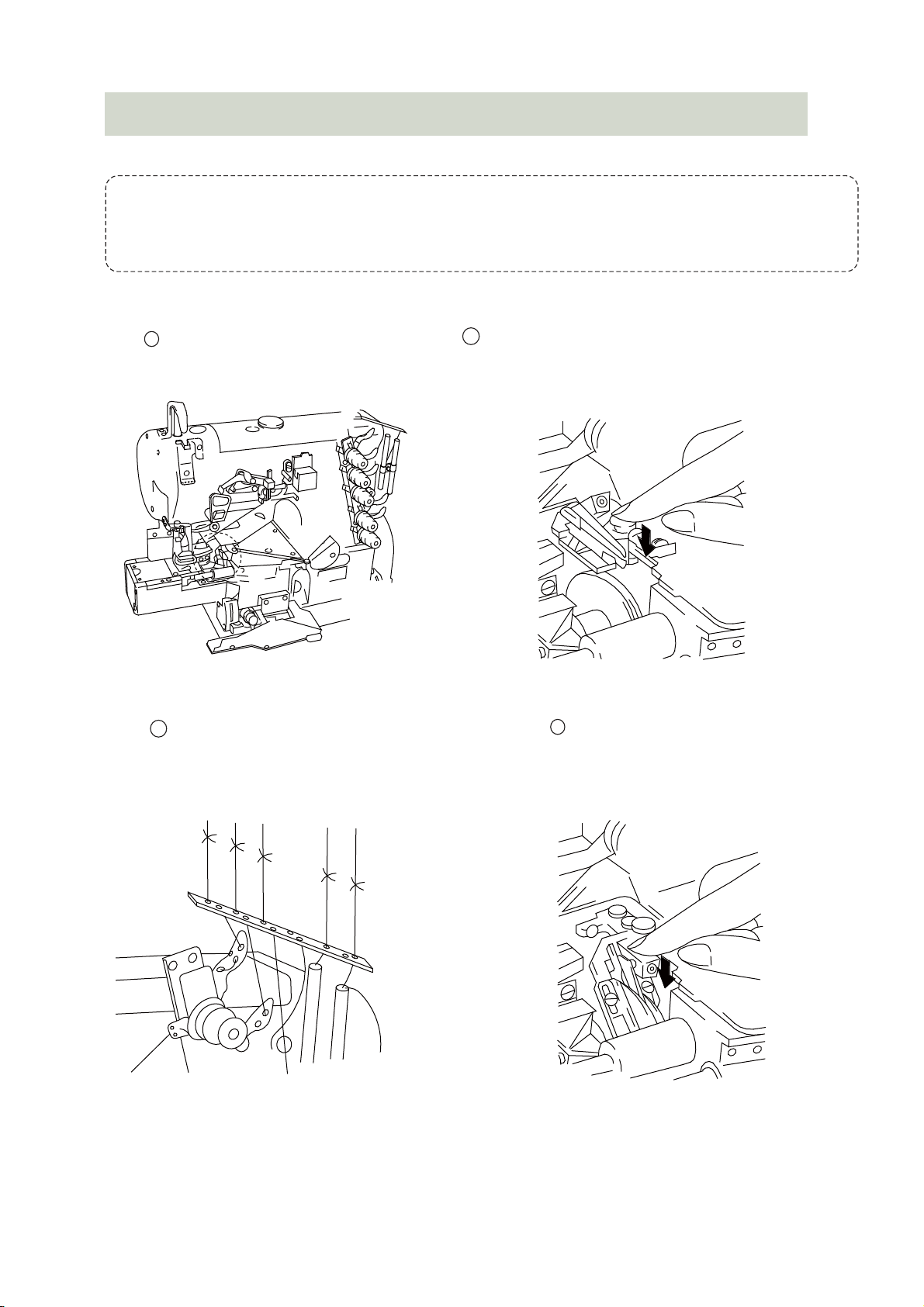

Replacing the needle, presser

foot, throat plate, feed dog and

sliding plate.

9.,,。

10.,。

The machine should not be placed next to a sound source as an ultra-

sonic welding machine and other equipment.

For your safety, goggles must be

used running the machine.

Turn off or unplug the machine

when the following situations arise:

W nance.hen the machine is in mainte

W nning the machinehen the operator is not ru

Maintenance and repair on electric

equipment should only be made

by qualified personnel.

If any elec

tric device is damaged, the machine

should be immediately stopped.

T atedhe machine should only be oper

by properly trained personnel.

The machine should not be run

without its safety devices.

Before running the machine, make

sure all relevant safety specifications

are adequate to specifications and technical standards in your country.

1.,。

2.。

3.。

4.,。

5.,:

a. 、、、;

b.;

c.。

6.、,

,,。

7.、、。

Repair, fitting or maintenance should only be performed by properly trained

personnel

8.,,

。

-2-