目录

Contents

I、规格

....................................................................................................................... 1

Specifications........................................................................................................1

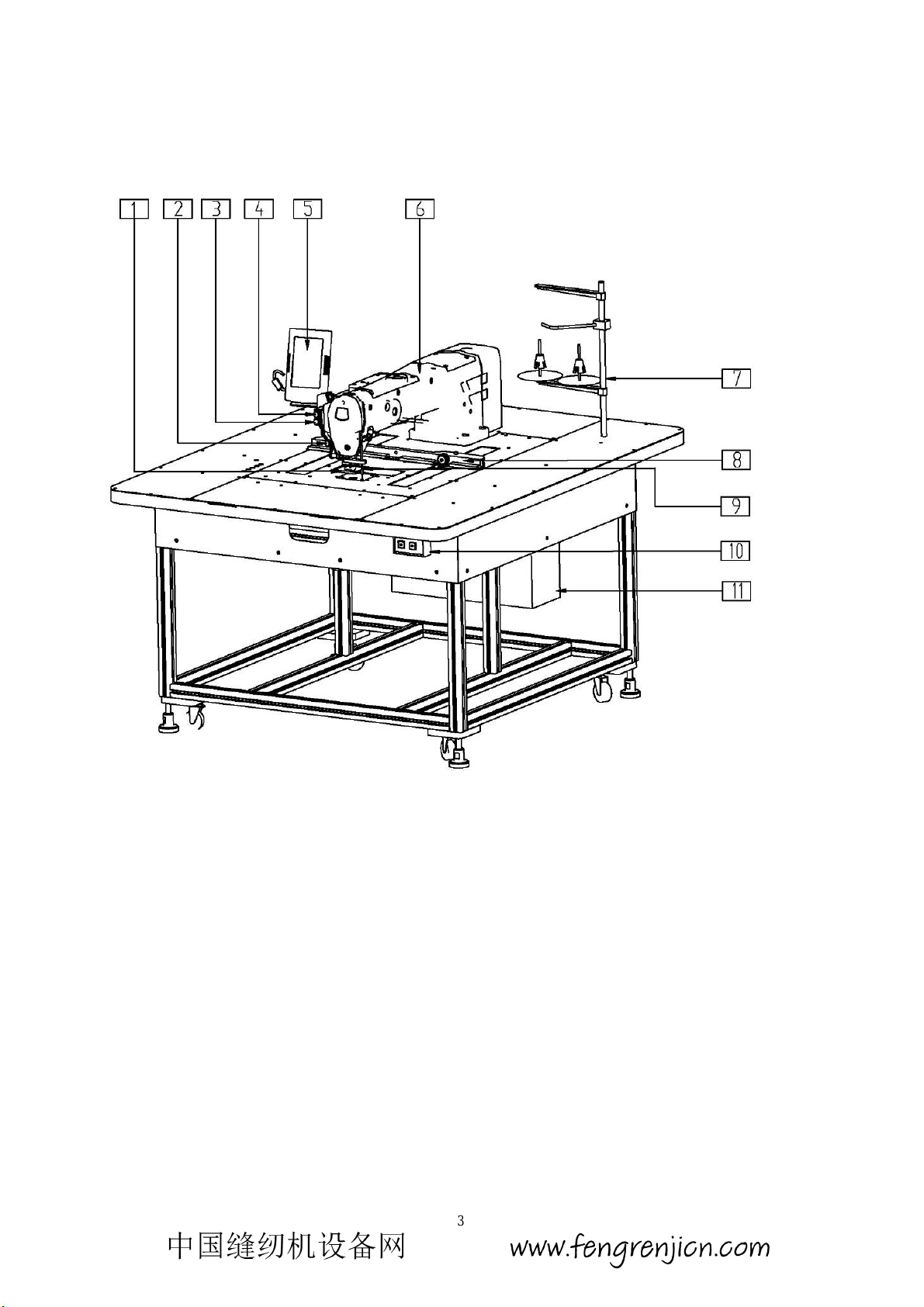

II、 各部的名称........................................................................................................... 3

Names of parts.......................................................................................................3

III、拆箱........................................................................................................................4

Unpacking.............................................................................................................. 4

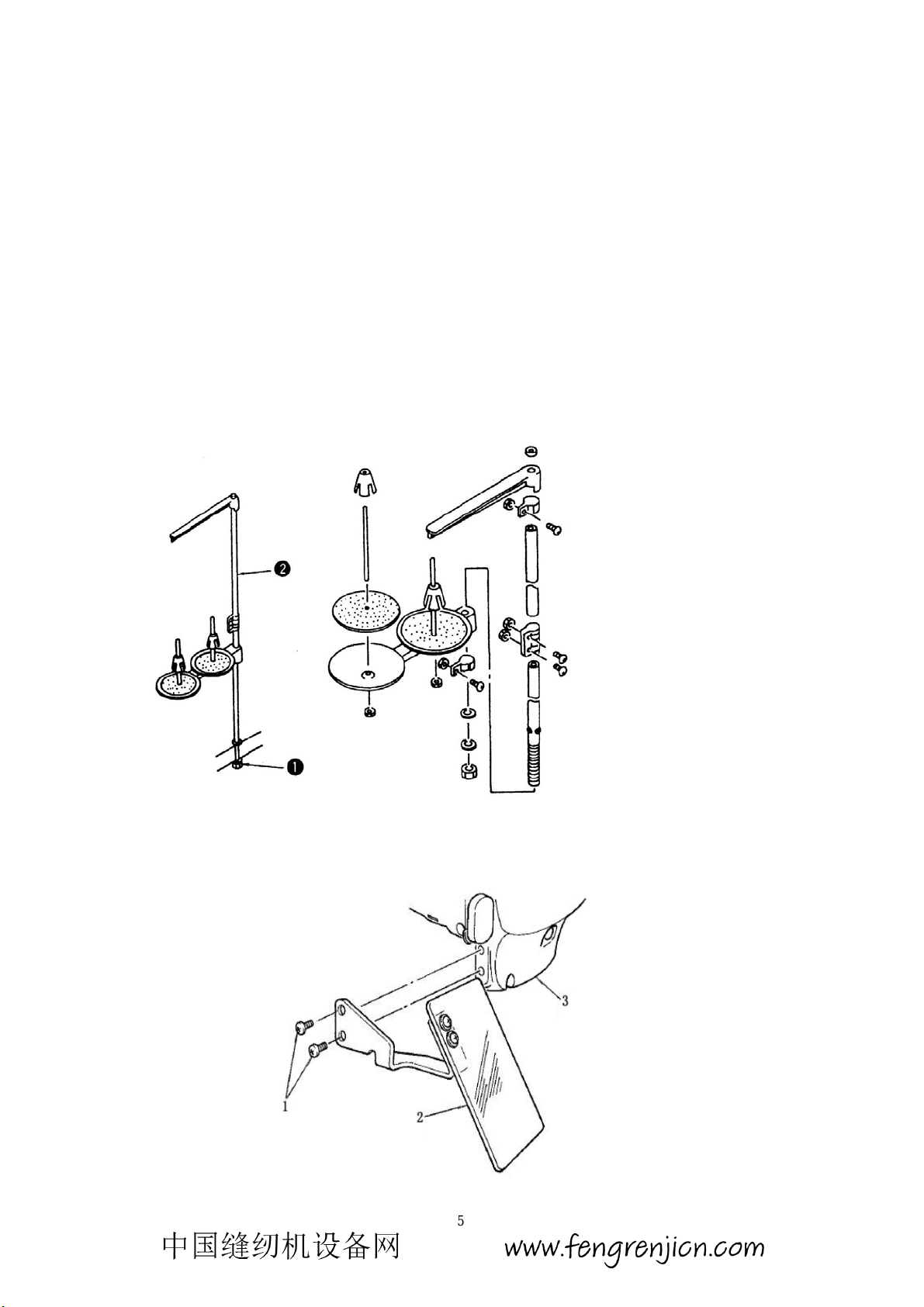

IV、安装.......................................................................................................................5

Installation..............................................................................................................5

V、 模板的制作...........................................................................................................6

Making of Template............................................................................................... 6

VI、缝纫准备................................................................................................................8

Sewing Preparation................................................................................................ 8

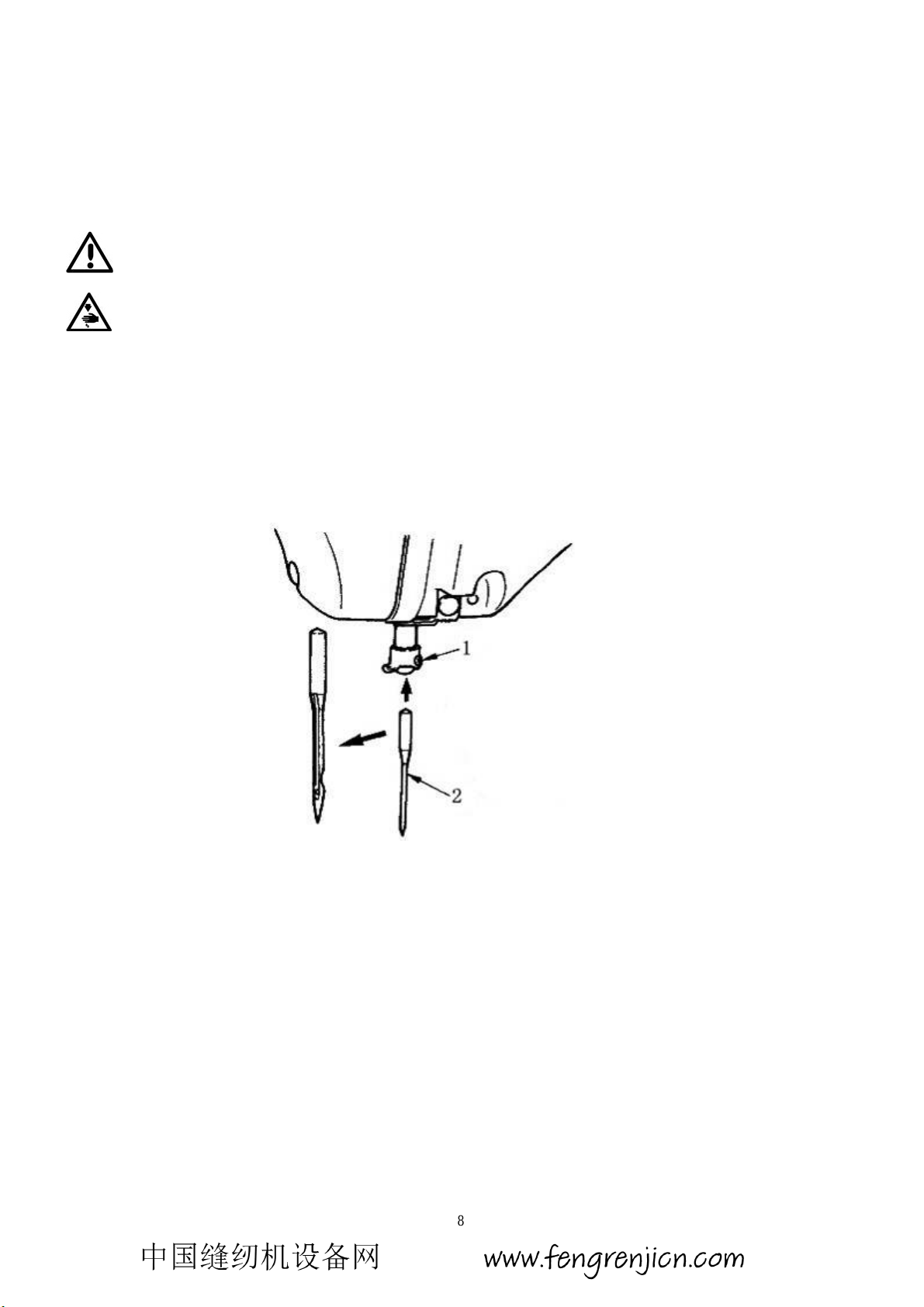

1、 机针的安装方法..............................................................................................8

Attaching the needlel........................................................................................8

2、 上线的穿线方法.............................................................................................. 8

Threading the machine head............................................................................ 8

3、 梭芯的安装方式.............................................................................................. 9

Installing the bobbin.........................................................................................9

4、 线张力的调整方法........................................................................................ 10

Broken stitching pickup plate.........................................................................10

5、 挑线弹簧的调节............................................................................................ 11

Adjusting the take-up spring.......................................................................... 11

6、 中压脚高度的设置........................................................................................ 11

Setting up the height of middle presser foot...................................................11

7、 压脚压力的调节............................................................................................ 12

Presser foot pressure...................................................................................... 12

8、辅助压脚的调节............................................................................................13

Adjusting the auxiliary presser foot...............................................................13

9、中压脚的上下行程调节................................................................................13

Adjusting the vertical stroke of the intermediate presser...............................13

VII、保养方法............................................................................................................ 14

Maintenance Method............................................................................................14

1、 针杆、压杆部润滑脂补充............................................................................ 14

Needle bar, pressure lever grease replenishing.............................................. 14

2、 中压脚提升部润滑脂补充............................................................................ 15

Presser foot lifting parts grease replenishing..................................................15

3、X、Y向齿轮部润滑脂补充..........................................................................15

Adding grease to gears (directions X, Y).......................................................15

4、 花键轴、导向轴润滑脂补充........................................................................ 16

Adding grease to the spline shaft and guiding axle........................................16