Template machine - Touch screen E2 General Introduction

2

1.2 Functions & Specifications

ASC400 Computerized Control System for Pattern Sewing Machine

X(Left/Right) YFront/Back¥

1300 x 800

3200rpmwhen sewing pitch is below 3mm¥

0.1Ǩ12.7mmMin. Resolution : 0.05mm¥

Intermittent Feed (2-shaft drive by stepping motor)

Max 25mmPneumatic type: Max 30mm¥

Intermediate Presser Stroke

Lift of Intermediate Presser

Double-capacity semi-rotary hook

Used to stop machine during the sewing

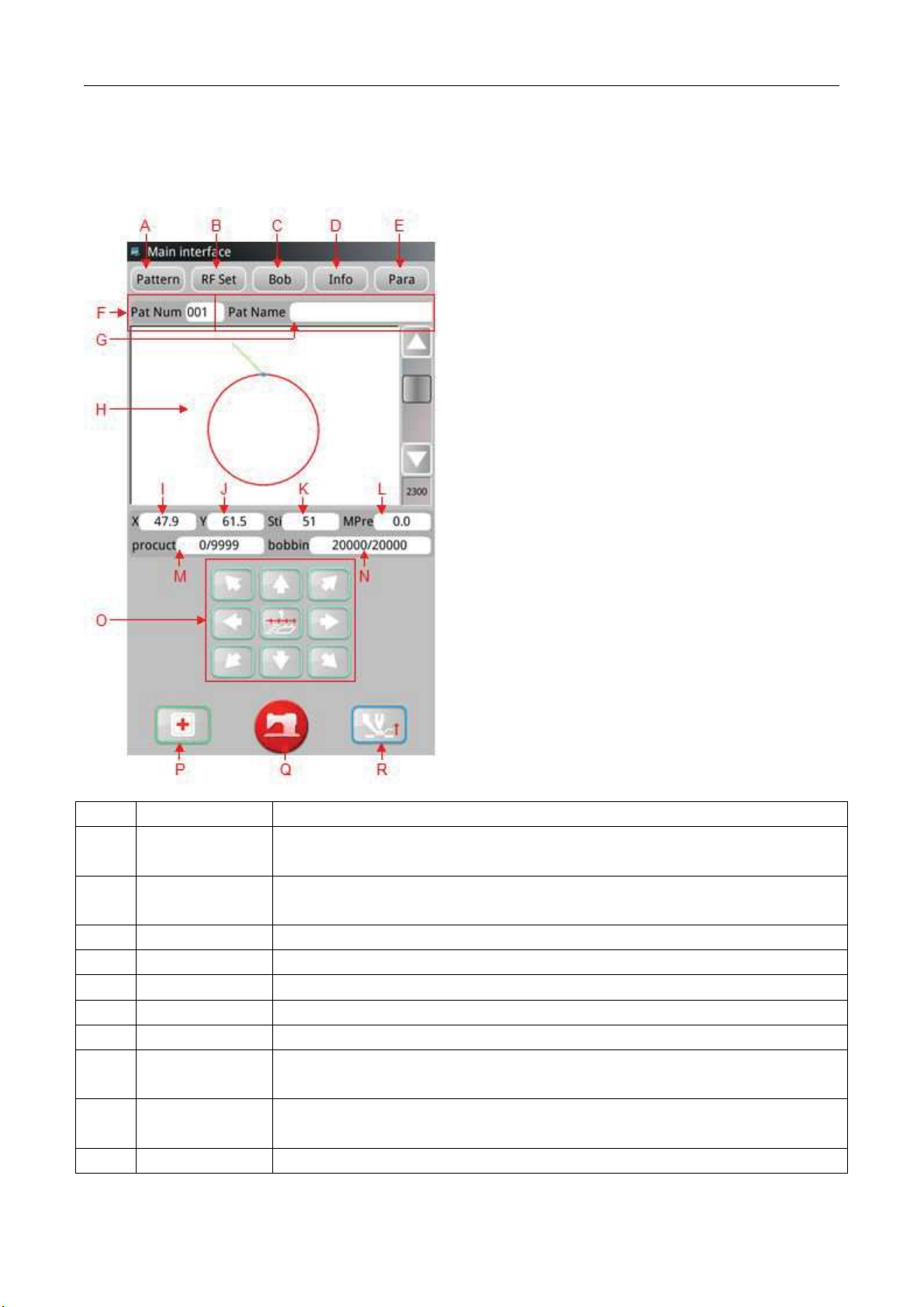

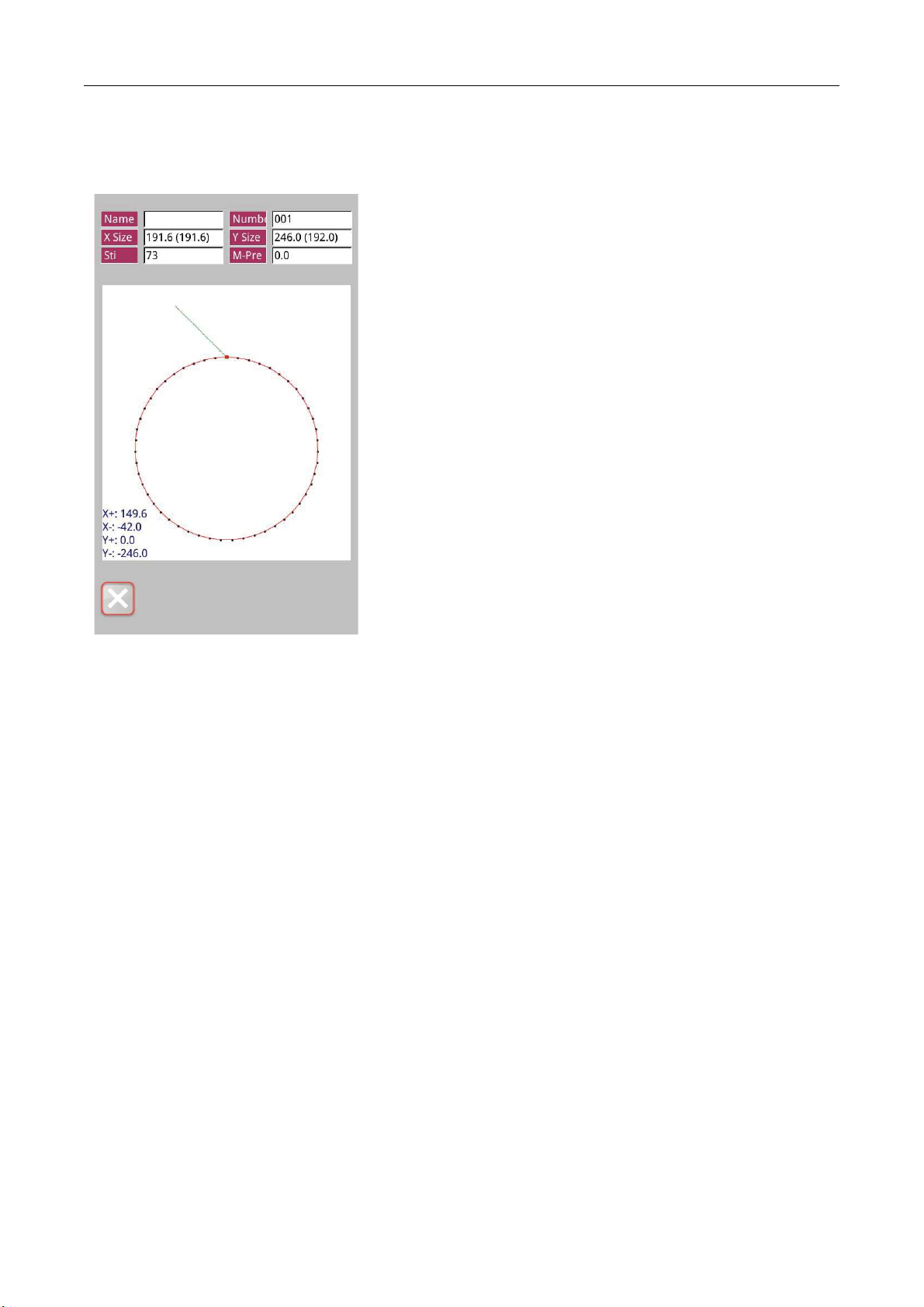

Enable a pattern to be enlarged or reduced in X or Y direction

individually when sewing a pattern

Scale: 1ǺǨ400Ǻadjust 0.1Ǻin each step¥

Method for changing the length of each sewing stitch

Limitation of Sewing Speed

200Ǩ3200rpmchange 100rpm in each step¥

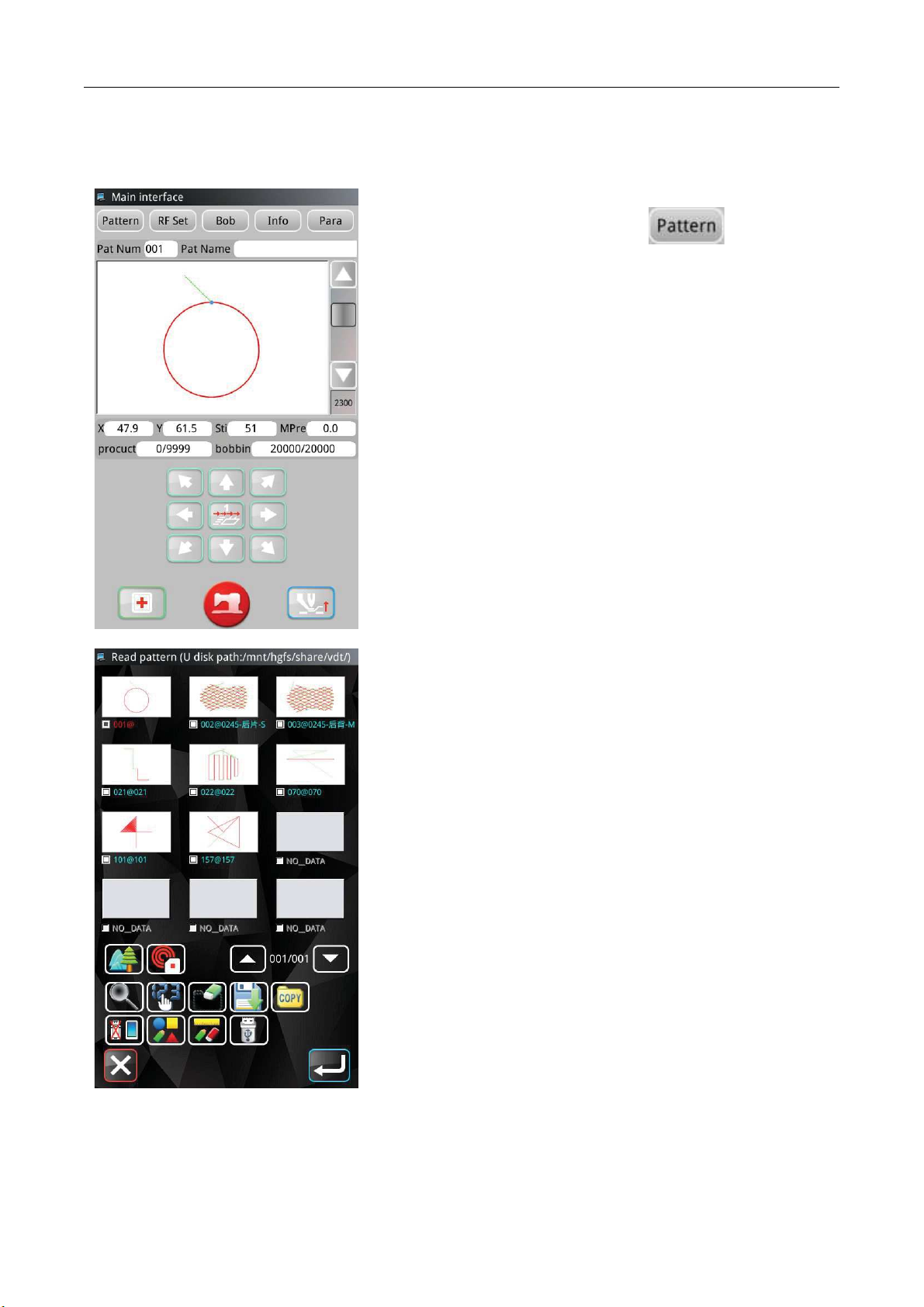

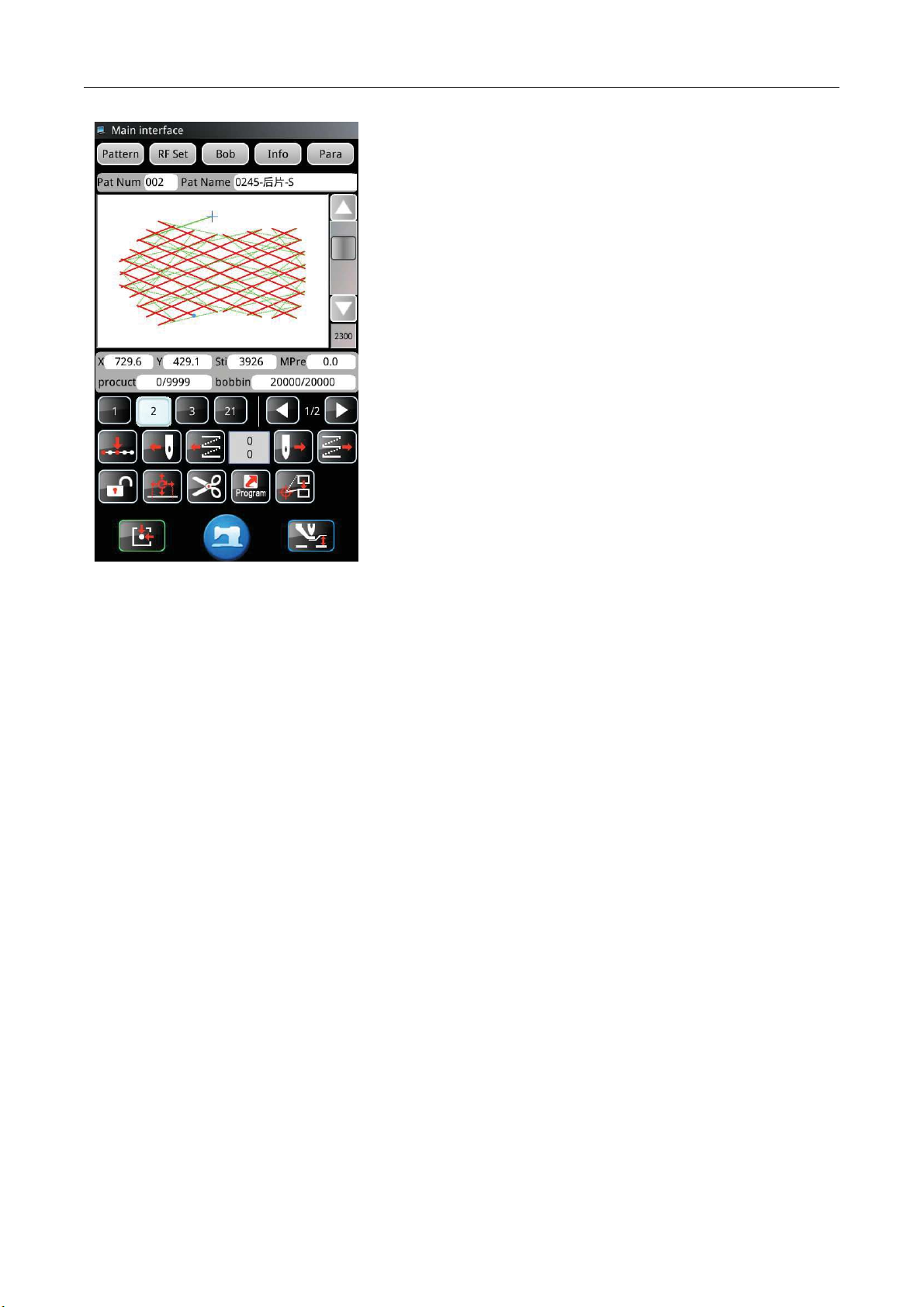

Function for Selecting

Pattern

Pattern Number Selection Method

Use manual switch to move the needle to a random position within

the sewing range and set that position as 2nd origin.

Function of stopping needle

at highest position

After the completion of sewing, the needle can be brought up to its

highest position.

Operation Temperature

Range

35%Ǩ85% No Dew Condensation¥

Effective standard for product:QCYXDK0004—2016ȎComputerized Control System for Industrial Sewing

MachineȐ.