1JE:

Jf1

i5t

~Jj

Operation Instruction

§I

~

CONTENT

1,

.:E~t!=*;E_.W,;ft

SPECIFICATIONS·········..

·················

o···.····...···.·····.o··......,.."......

·j

2,.

~f!=§tr1tf£$::I~m:

BEFORE OPERArlON····································o····o·······.,····..·····

·i

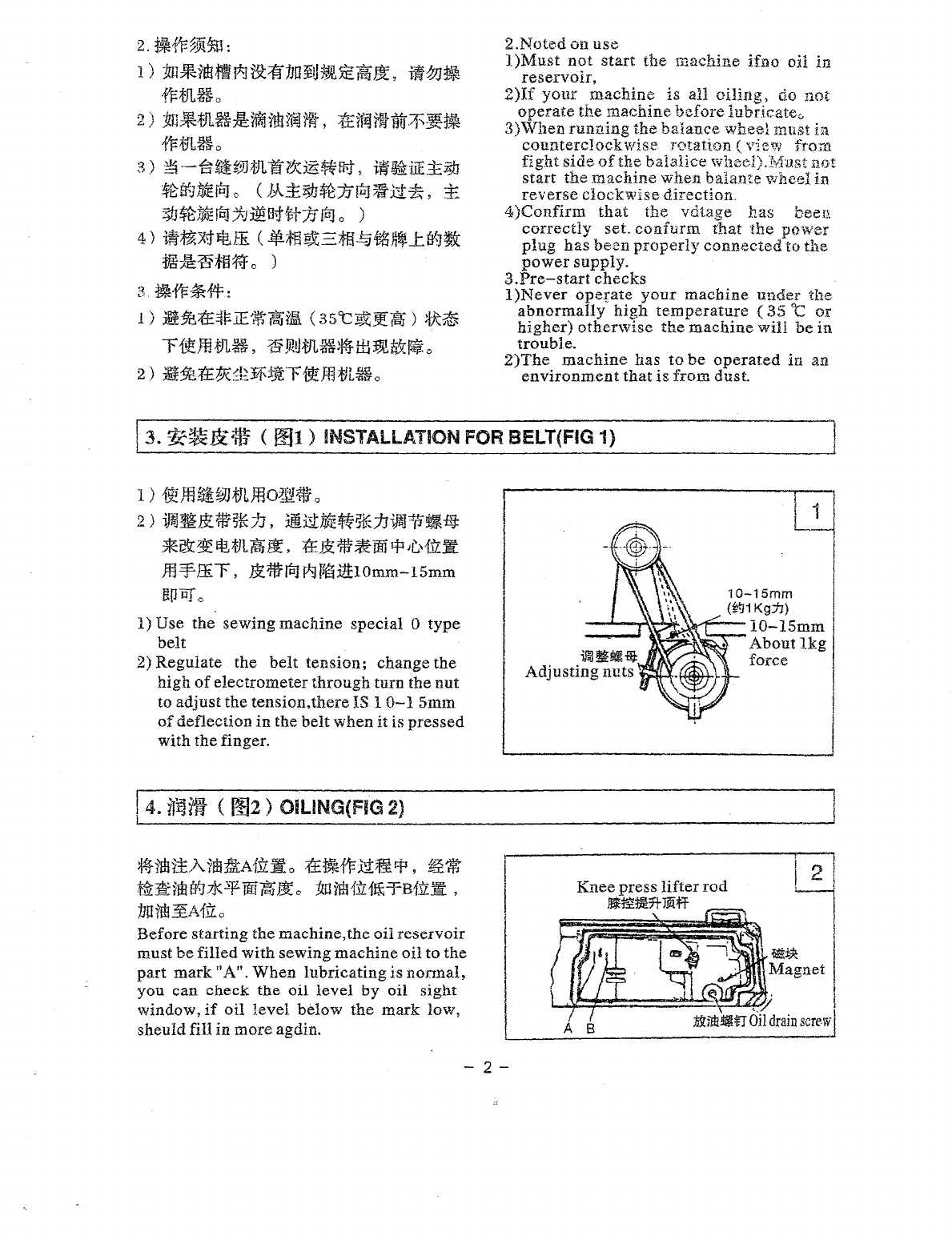

3,

5te~~$

Installation for

belt

································································o···········2

4.,

ii~Jj~

Oiling

•........

o

••••••••••••••••••••••••••.••••••••••••••••••••••

o

•••••••••••••••••••••••••••••••••••••

2

5

.:rh·~·ll·~~·r<:<t=.-:a

'T}-,,

.,;t··

t'

;:·,,·1·

..,

l!rl

~fl·J

i~

d~

1.11..

.1

.1

....

S1

Ua

10D

01

vl

111g

• • • •• •

••

••

•

••

•.

•.

••

• • • ••• • • • • • •• •

·-

• • • •• • • • • •• • • • •• • •• • • • • •• • • •

•••••••

3

6

...

Ml~~jfi17~a·'~1;~~

To

adjust the oil feed to rotating hook ··············································3

7

...

1til*a9iJ~ftt

Oil purnp supply adjustment

...............

o.

..............

oo

......................

o••····3

8.,.

:iElt81!]~fJl.ilf.I'criodical

r.:::Jeaning

·····································································3

9.~

~~!Ji$.'jgifl

Fixing belt

cover···"·········

•o

••

• • •

••

•••

••

• •

•••

•

••••

•

•••

• •

••••

• •

•••••

• •

••

•

•••••

••••••

•

••

•

·4

"'

0

.,

i~

~

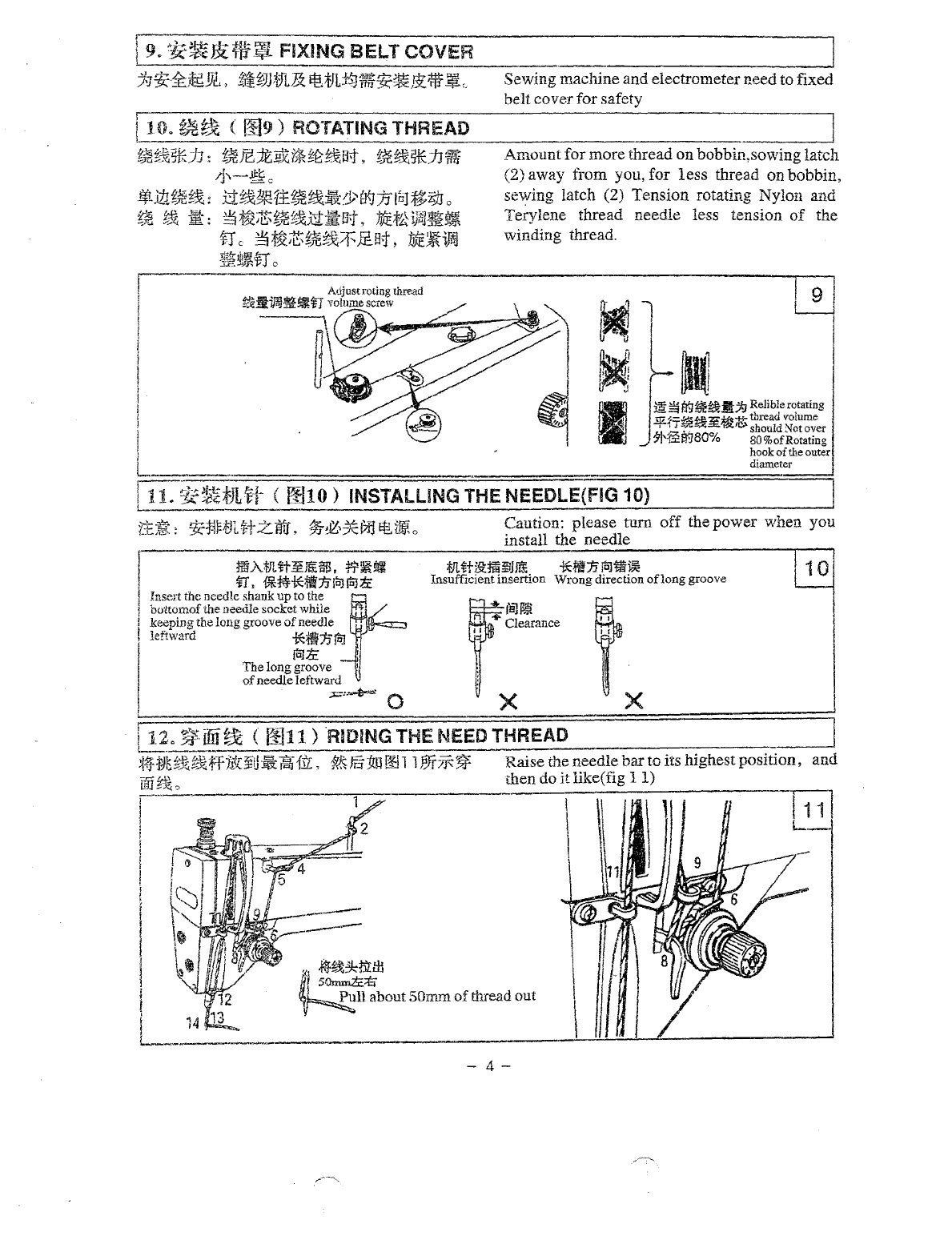

·Rotating thread ··· ··· ··•····· ·········

··

·············· ··········,········•····•·················o • • •

4.

1

i,

7}':2-~~fLti-

InstaUingtheneedle

............

,.

....

,,

......................................................

4

12.,

:§.f

[§1

~

Itiding theneed thread ····

·"

······

··

·········•·············

"·

···························

~

··

.,

····4

i

3..,

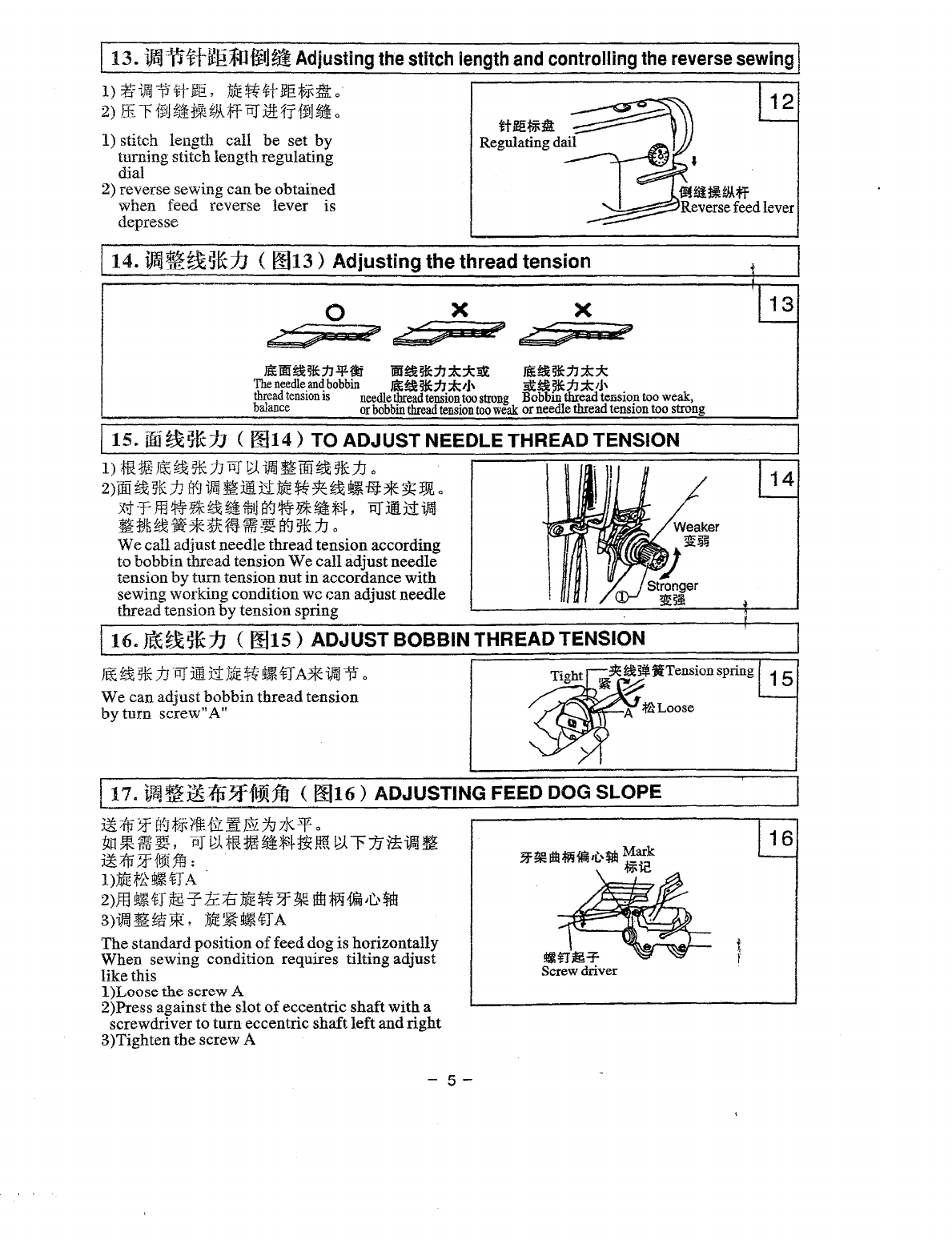

i~:PttgE~Q'fi!j~

Adjusting the stitch length

and

control11ng

the

reverse

sewing··················

5

",

1

-'

••

;~?S!?1r.~flJL-r-,

A.rt'

. h h d .

'"t

_

',%or:;J

xili~

JIA.J

,~

......Jusnng t c t

rea

tension······························································

5

·j

5,.

im~B-h::'h

To

adjust

need.1e

thread tension

...•..........•....

··.··········•·····························

5

16,

J~~~~1J

Adjust

bobbin thread

tension·····

...

·•·•••·••···•·

..

·••·••••···••···•

......

•·••••··••••···••

5

17

...

iJ~~~;fji

3f{&m-m

Adjusting feed dog

slope······················

..

··················

..

···············

5

i

8,

tt:f.&~.§_

14=1¥-J~~

Fixing the throat

plate······························································

6

i 9

...

i]j

JJ

tf.J~~J:i~1~

Operatingand fixing

of

trimmer

··

··

···

····

·-~

·

··

··

··

··

·

······

····

··

···

··

······· 6

20-.

~~~:f'Li&:f.&atliJ!Jf.l

Using the waste materia1

guide····

...........

:

.........

···········•o···········7

21,.

~'E~1!f:lf1£~

Changing

other

parts································································

7

~1t:f:*$*

Parts

Book

1

..

*Jt~=giH*A.rm

bed

components······························································B-9

2..

...t~~t*'f~~~$14=

Arm shaftvertical shaftneedle bar and thread take-up······

·1

0-11

3

..

f~3F~~H}~~f4=

Needlebarand thread tension components

...........................

12-13

4"'

ttHE!iJI.IT.i"~~14:

Stitch length regulating mechanism

................................

~···14-

i 5

5,

ffiJWJ~iH!f:

Presserfoot

p<rrts

.................................................................

·16-17

6,

i;JJJJ1~$1J$14Knife

controlmechanism··················································18-19

7..

jj!j~$itf:

Lubrication

mechanism·························································

·20-21

8,

iftt&

...

llft1!.f:

Oil reservoir and accessories

................................................

22-23

From the library of: Superior Sewing Machine & Supply LLC