COMPUTER-CONTROLLED HIGH SPEED LOCKSTITCH BAR TACKING MACHINE

i

CONTENTS

I. EXPLANATION OF COMPUTER-CONTROLLED HIGH-SPEED LOCKSTITCH

BAR TACKING MACHINE

[1]SPECIFICATIONS..............................................................................................................................1

[2]CONFIGURSTION..............................................................................................................................2

1. Names of main unit................................................................................................................................2

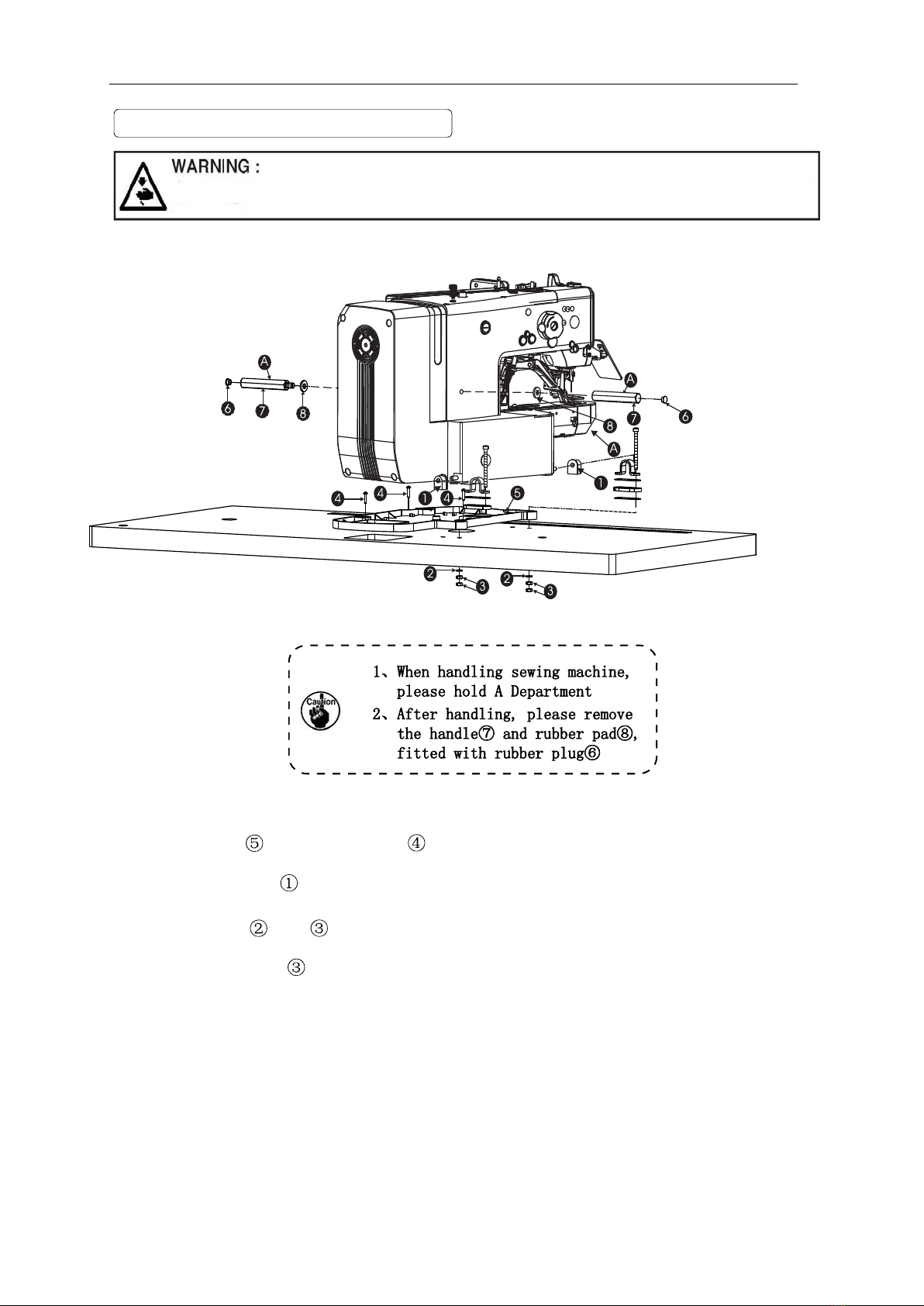

[3]INSTALLATION..................................................................................................................................3

1. Attaching the connecting rod................................................................................................................3

2. Installing the head support rod..............................................................................................................3

3. Installation of the sewing machine head..............................................................................................4

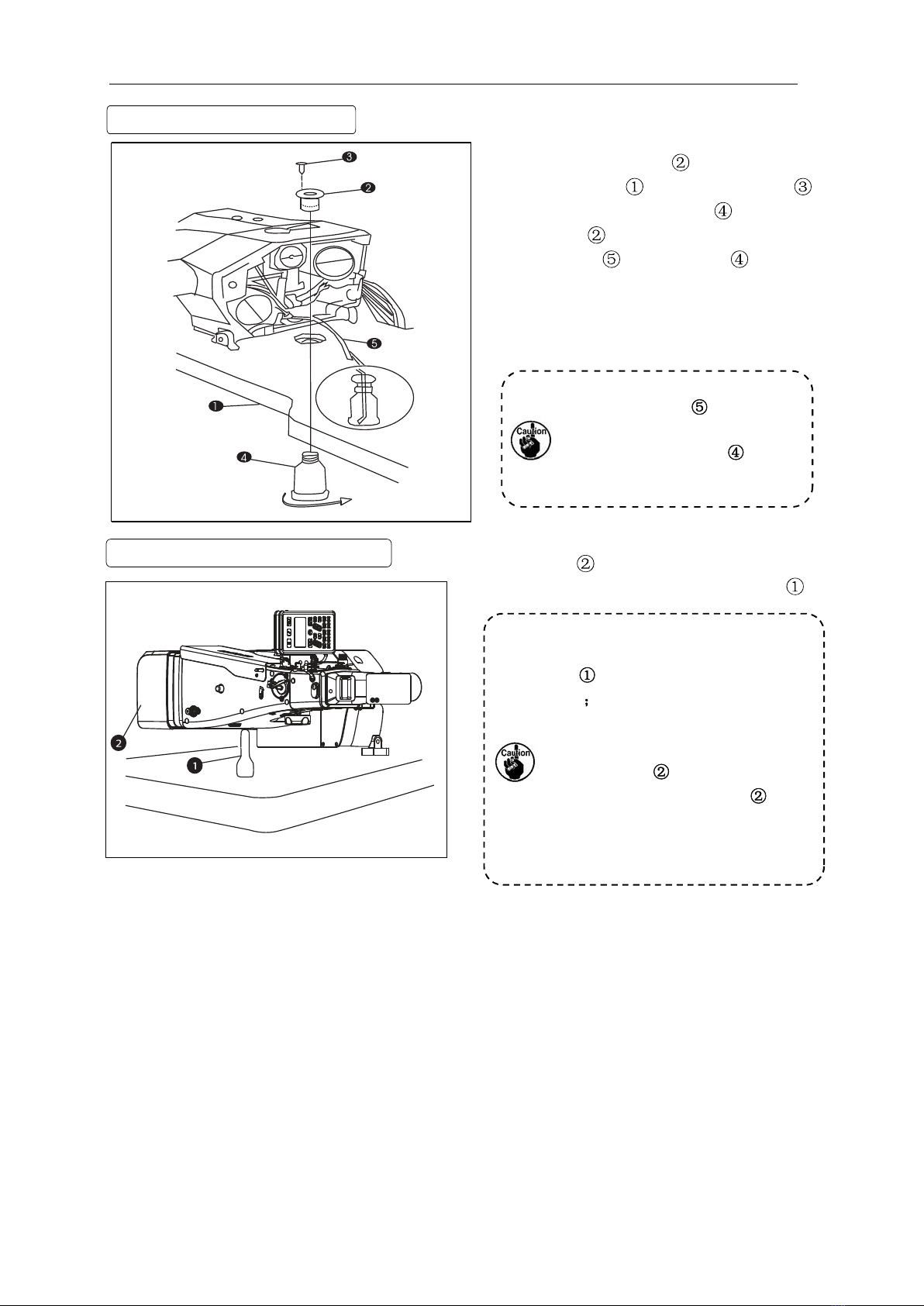

4. Installing the drain receiver...................................................................................................................5

5. Tilting the sewing machine head............................................................................................................5

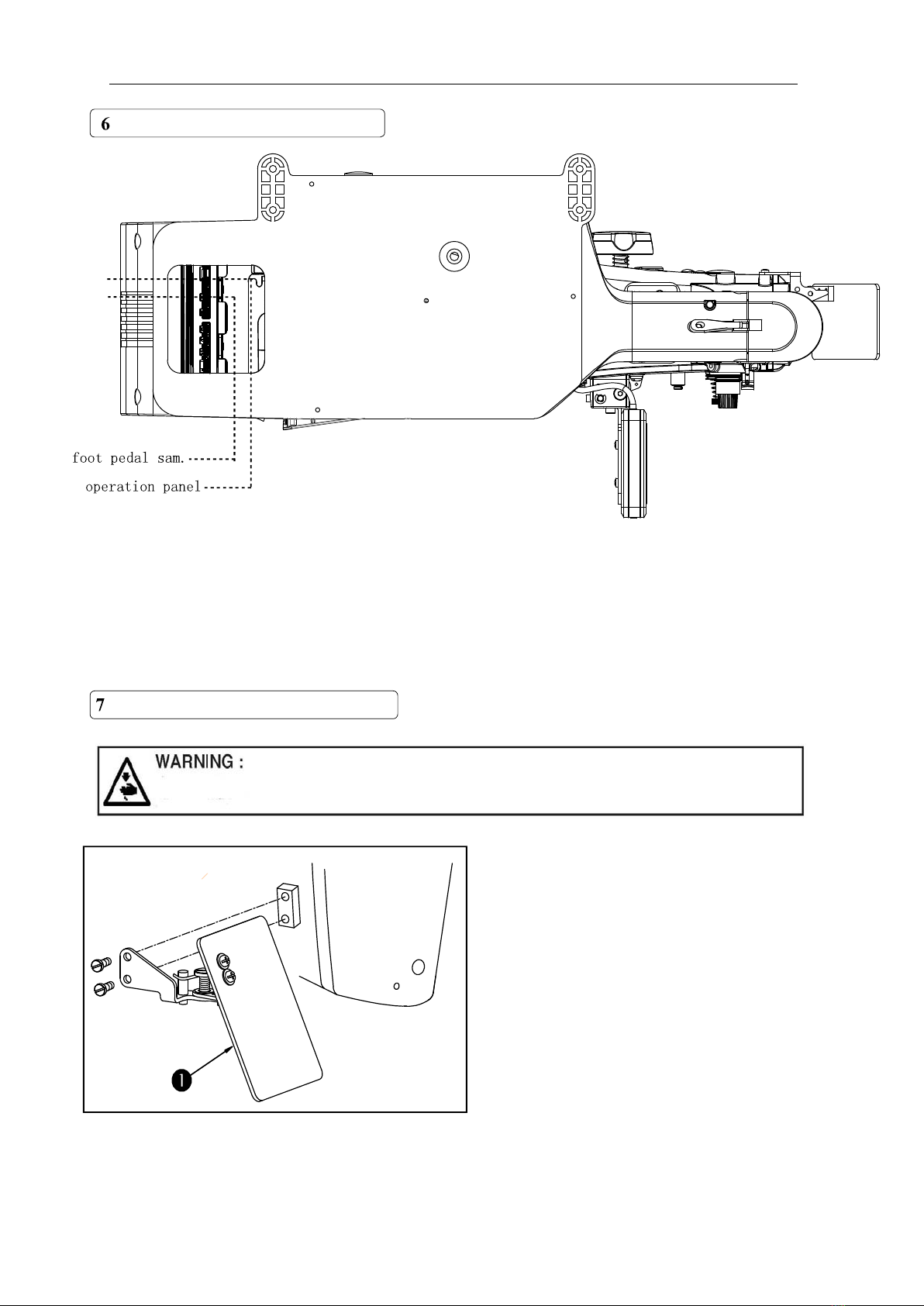

6.Connecting the operation panel..............................................................................................................6

7.Installing the eye protection cover..........................................................................................................6

8.Installing the thread stand.......................................................................................................................7

[4].OPERATION OF THE SEWING MACHINE...........................................................................7

1. Lubrication...............................................................................................................................................7

2. Attaching the needle................................................................................................................................8

3. Threading the machine head.................................................................................................................8

4. Installing and removing the bobbin case...............................................................................................9

5. Installing the bobbin................................................................................................................................9

6. Adjusting the thread tension..................................................................................................................10

7. Adjusting the thread take-up spring....................................................................................................10

[5]MAINTENANCE.................................................................................................................................11

1.Adjusting the height of the needle bar.......................................................................................11

2.Adjusting the needle-to-shuttle relation....................................................................................11

3.Adjusting the lift of the work clamp foot..................................................................................12

4.The moving knife and counter knife...........................................................................................13

5.Adjusting the wiper..........................................................................................................................14

6.Draining the waste oil......................................................................................................................14

7.Adjusting the amount of oil supplied to the hook...................................................................14

8.Replenishing the designed places with grease..........................................................................15

9.Adjusting the position of the shear driv pulley................................................................ 16

10.Position the wire- ing safety sensor and the wire- cam........................ 16

[6]Table of the standard patterns and standard clamp foot...............................................18

[7]Table of the optional parts ...........................................................................................................20

II.EXPLANATION OF COMPUTER-CONTROLLED HIGH-SPEED LOCKSTITCH

BUTTON SEWING MACHINE

[1] SPECIFICATIONS............................................................................................................................21