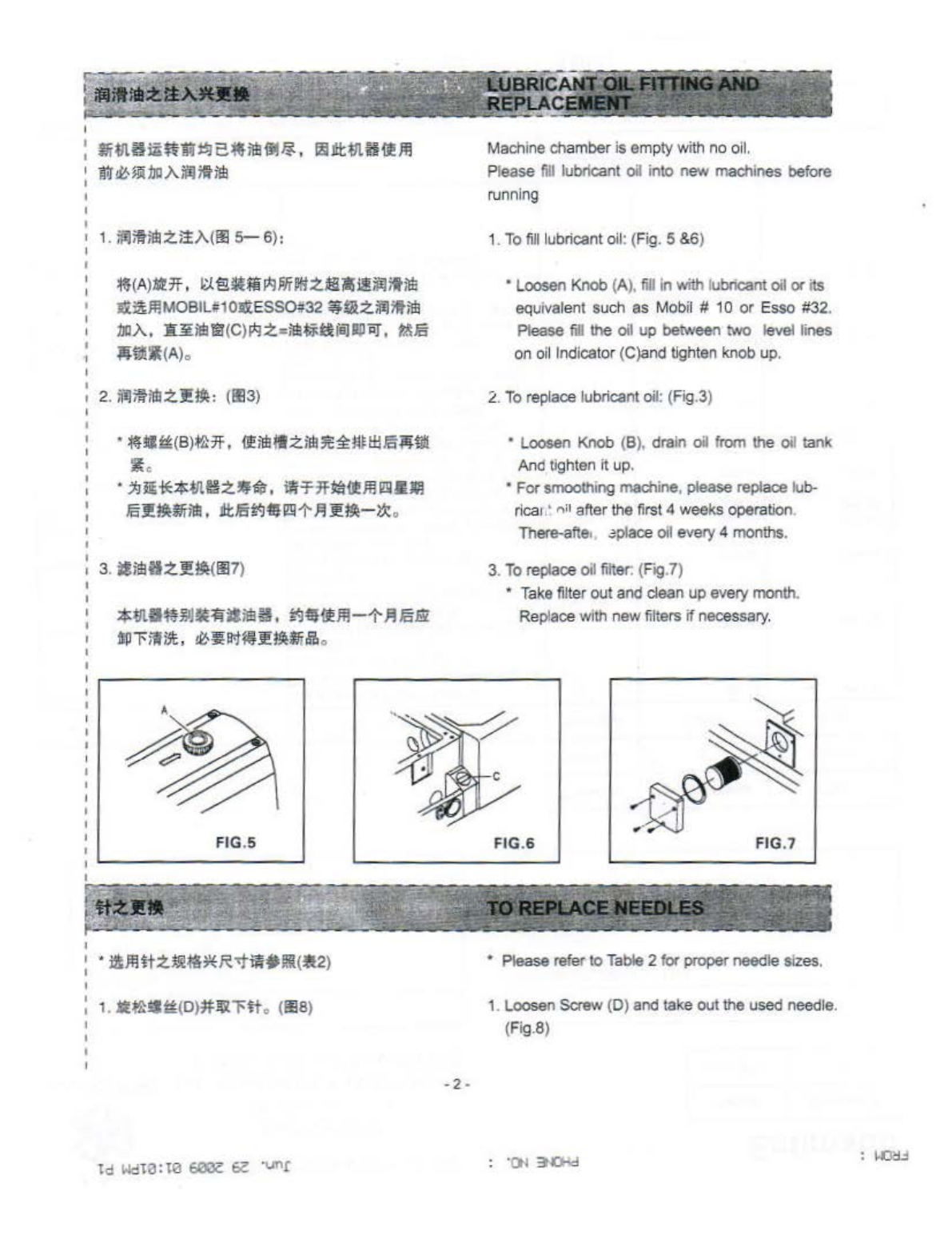

2.

~llitt!i.Mtl1£ztHt.~•~~•.

~~ttzl!!l

ii!Itolti:

.

3.

_.iiU!!\UI~(D)

o

4.

~-tt:ie~:fiHil,

:f@~~I81Jttf#jiti,

i1E

~t!~Zltt,

~&&iUt

.

Table(

~

1)

~~

/

:St

M/C

Pulley

SiZe

{mm)

S.P.M

60Hz

50Hz

4500

90

105

4000

80

g.;

3500

70

85

~-~~llllil:if-iit~ttzJJt:!!.

m~z!!1~~5

1

~~~.-tt~$~:f~~~~~.~-llll~~

Jl\5~

.

2.

-?±;J~tt~ll't,

Q:tlf~tt.li511ti~(lll10)iSliU:'k

~toJttlti~~tt.litoJn~w.~s~rr!J~

.

1.

~t!lsU~&&~~~~*!!<ii~~•.

Jll!§>.

~

ll(Jf:i

~

~

$tlll(Jtt

ietf:f

liJ

illii!H

liJ

zi.ll§.

:tlf~tUl!UIIofttJ'ftoltt~B<JtU!IIIl(

.

&z

"'Jill~

.

2.

tt~t&~:tW§(III

1

1)

tttl!£tl~(B)

R'<tiU!!~Jll

ifl!l

~

*iiU

~if

lfltl:~,

~loll

f%!i

(A)~(B

)

l:

1'3

i;l)iiiJ

Jl,

f:E

(i}ll1'$Jit!£

:kll(J!il!lt'.t~<B>..t3.

&z

l'.\J

2.

Pu1

new

needle into

the

needle

damp

holes as

faras lheycan

go.

The scarf

of

needle should

be

on left side.

3.

Toghten

Screw(D).

4.

lmpi"O?Eir

needle setting wifl

cause

skipping

stitches, breaking threads,

and

damaging

loopers. Please

pay

attention

to

needle

installation.

X 0 X

FIG.8

k--~··

~

sr_,t.-

~~

,

-

~

-::..'

.•

..

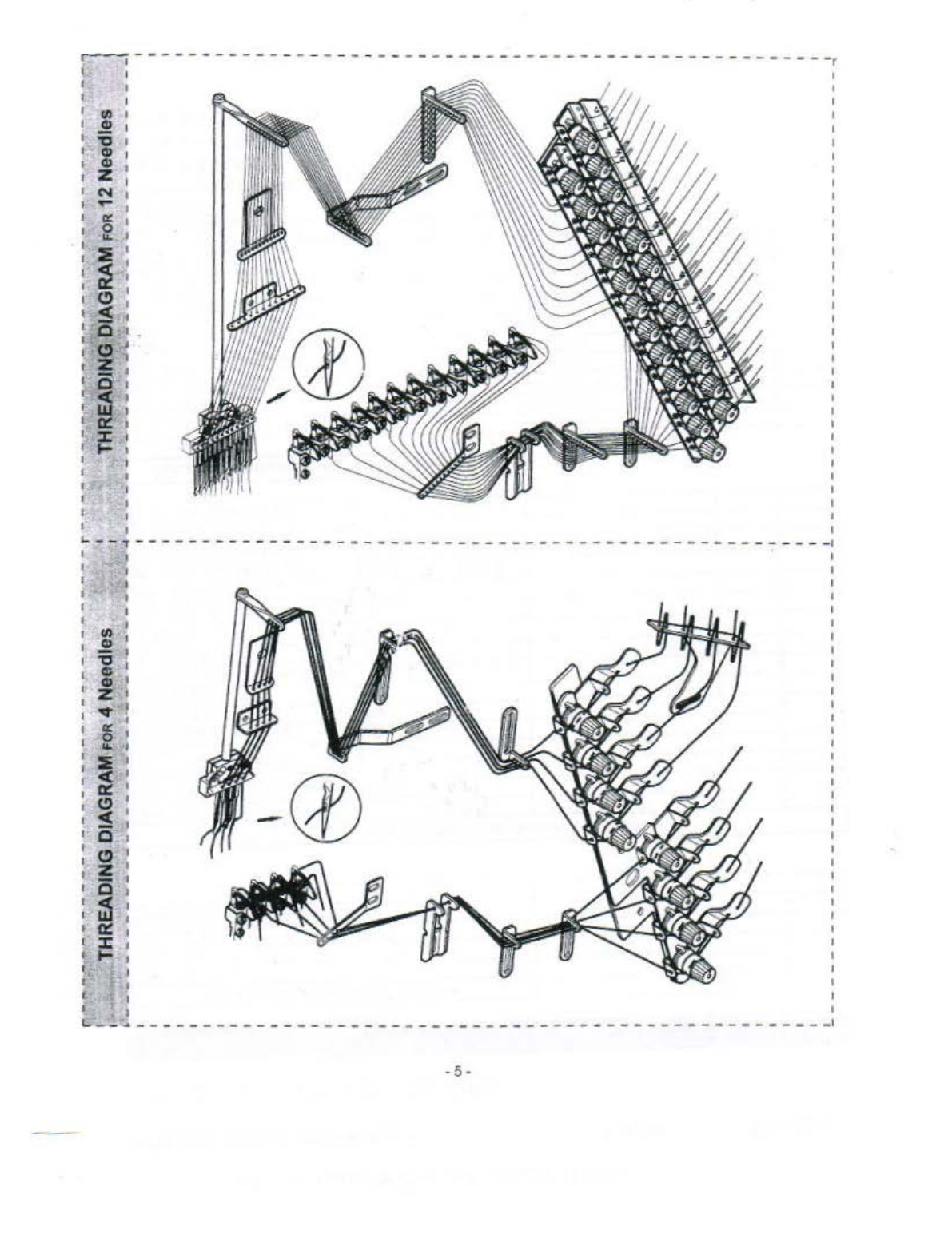

1. For

needle

threading. please thread carefully as

threading inustration page

5.

Please note: impro

per threading will cause breaking threads,

skipping stitches,

and

I

or

undesired sewings.

2. For looper threading, pull outthe lever "P" of

looperset as

the

arrowdirection then thread them

properly.(Fig. 10)

I

1. Thread

tensiOn

should be adjusted in

accondlng

to:

fabrics,

tl1ickness

offabrics. material, thread used 1

and

stitch length etc. 1

I

Tum thead-knob dockwise for

T~ghter

tension

and

:

vice versa.

2. T

akiH.I

p leveradjustment (Fig.11)

The position of Needle Thread

Take-up

Lever (B) 1

is adjustable according

to

thread used.

Loosen

Screw

(A) ,move Lever(B) up

and

down for the

optimum position. Forinstance,

·3·

From the library of: Superior Sewing Machine & Supply LLC