1

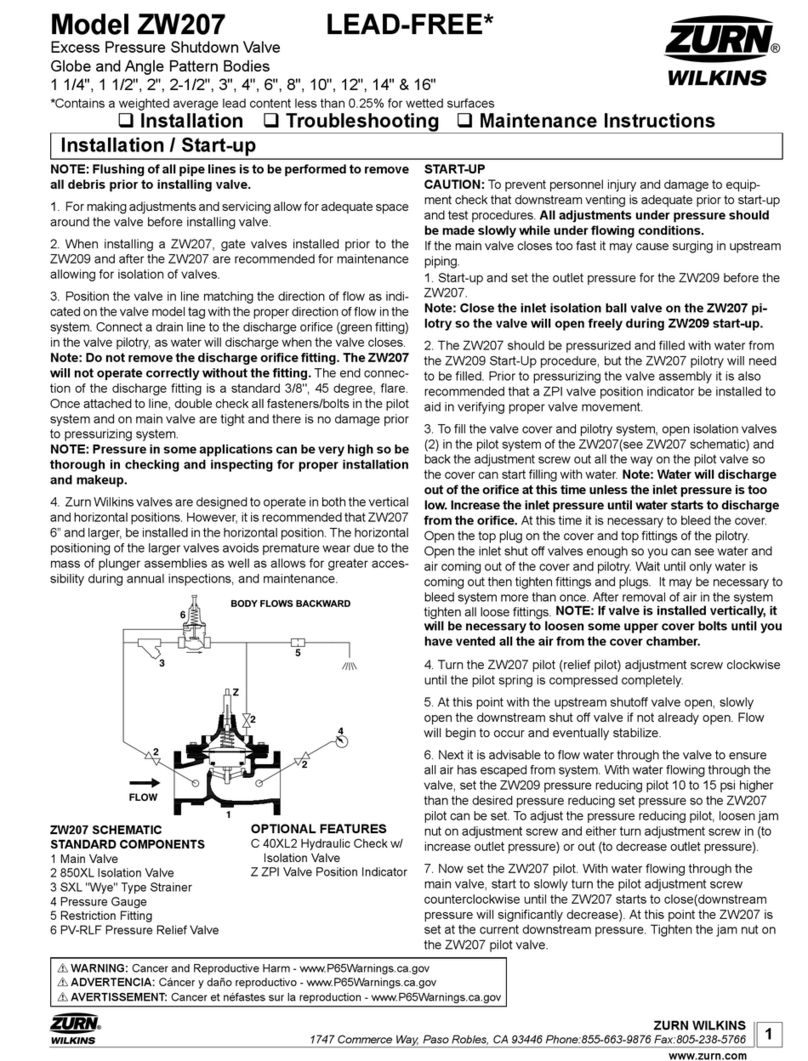

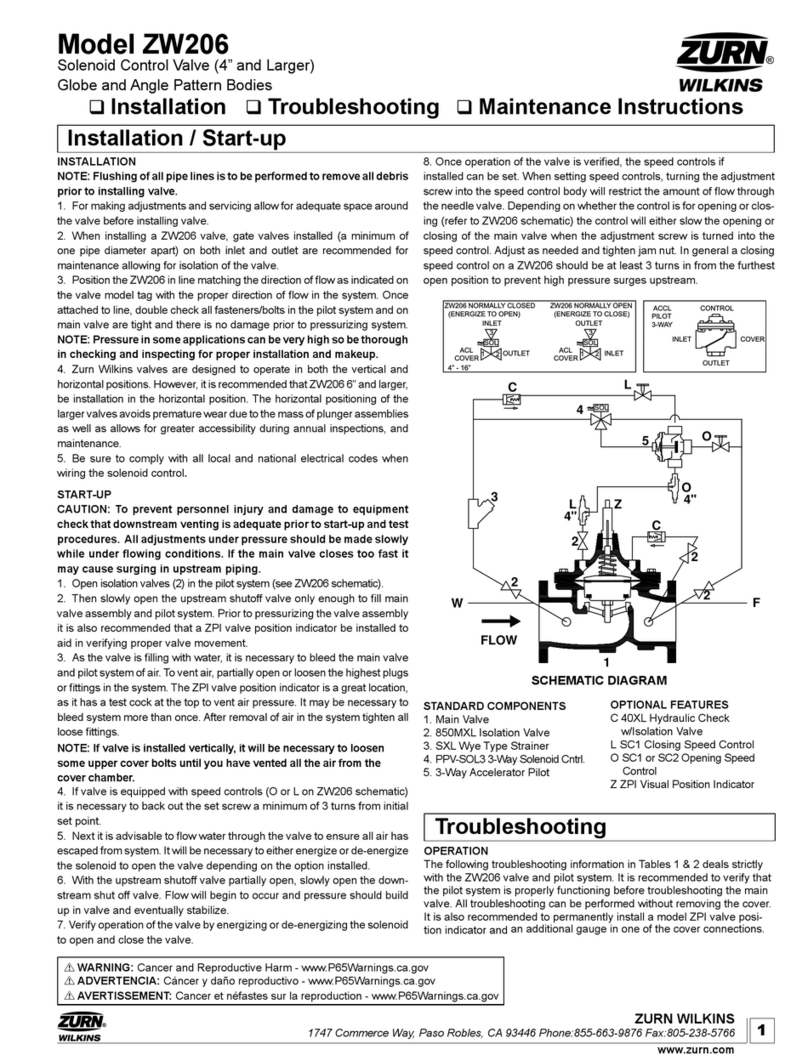

INSTALLATION

NOTE: Prior to installation of the ZW209FP, ensure that all

1. During the installation of a ZW209FP in a sprinkler system,

Underwriter Laboratories (UL) requires NFPA 13 “Standard for

Installation of Sprinkler Systems” be followed.

2. Upon installation UL also requires that the ZW209FP be

tested in accordance with NFPA 13 or NFPA 14. Thereafter the

valve shall be inspected, tested, and maintained in accordance to

NFPA 25 “Standard for the Inspection, Testing, and Maintenance

of Water-Based Fire Protection Systems”. NOTE: Initial testing

must be done with the design inlet pressure so the proper

3. For making adjustments and servicing allow for adequate

space around the valve.

4. When installing a ZW209FP valve gate valves installed on

both inlet and outlet are recommended for maintenance allowing

for isolation of valve.

5. Position the ZW209FP in line matching the direction of as

indicated on the valve model tag with the proper direction of

in the system. Once attached to line double check all fasteners/

bolts in the pilot system and on main valve are tight and there is

no damage prior to pressurizing system.

NOTE: Pressure in some applications can be very high so be

thorough in checking and inspecting for proper installation

and makeup.

6. Valves installed in sprinkler or standpipe systems shall have

the following:

a) Unions or rubber gasket installed immediately up

stream or downstream to permit replacement.

b) A relief valve (at least ½” size and 175 psi max.) installed

on the downstream side and plumbed to a safe drainage.

c) Pressure gauges installed on the inlet and outlet.

d) Shall not be set for less than 50 psi.

Installation Start-up Maintenance Instructions

Fire Protection Pressure Reducing Valve Assembly

1-1/4", 1-1/2", 2", 2-1/2", 3", 4" & 6"

ZURN WILKINS

1747 Commerce Way, Paso Robles, CA 93446 Phone:855-663-9876 Fax:805-238-5766

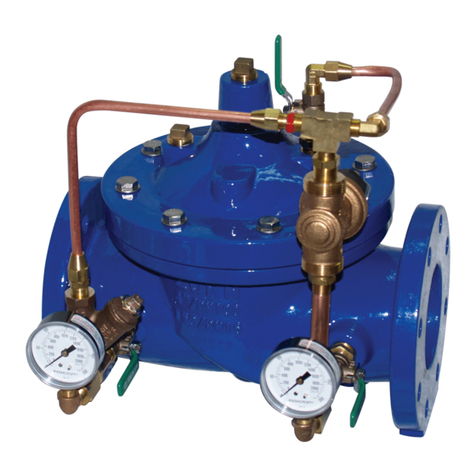

ZW209FP

Class 300 Flanged

Max 300 psi Inlet

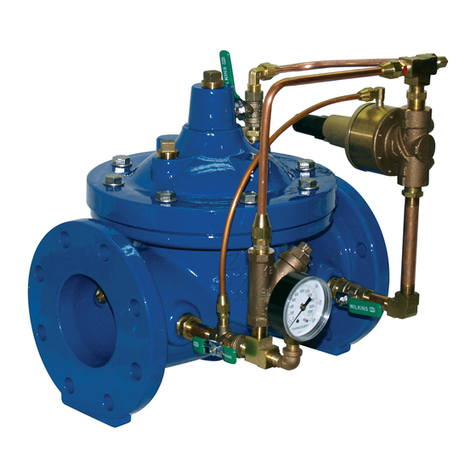

ZW209FPG

Grooved

Max 300 psi Inlet

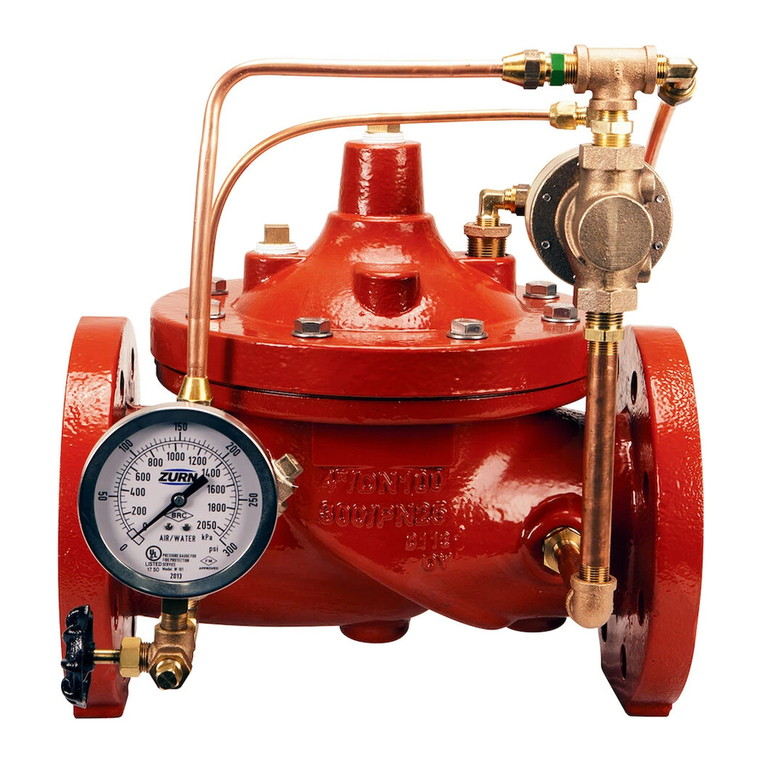

ZW209FPX

Class150 Flanged

Max 250 psi Inlet

7. It is suggested that a line size tee connection be installed

downstream of sprinkler system valves to allow full testing

as required every years per NFPA 25.

.metsysrelknirpsdnaresirylppusmorfriadeppartlladeelB.8

Trapped air may cause outlet pressure at low

9. Zurn Wilkins valves are designed to operate in both the verti-

cal and horizontal positions. However, it is recommended that

ZW209FP’s 6” and larger, be installation in the horizontal position.

The horizontal positioning of the larger valves avoids premature

wear due to mass of plunger assemblies as well as allows for

greater accessibility during annual inspections, and maintenance.

START-UP

CAUTION: To prevent personnel injury and damage to equip-

ment check that downstream venting is adequate prior to

start-up and test procedures. All adjustments under pressure

If

the main valve closes too fast it may cause surging in upstream

piping.

1. Slowly open the upstream shutoff valve only enough to

main valve assembly and pilot system. Prior to pressurizing the

valve assembly it is also recommended that a ZPI valve position

indicator be installed to aid in verifying proper valve movement.

2. As the valve is with water, it is necessary to bleed the

main valve and pilot system of air. To vent air, partially open or

loosen the highest plugs or in the system. The ZPI valve

position indicator is a great location, as it has a test cock at the

top to vent air pressure. It may be necessary to bleed system

more than once. After removal of air in the system tighten all

loose

3. At this point with the upstream shutoff valve partially open,

slowly open the downstream shut off valve. Flow will begin to

occur and pressure should build up in valve and eventually

stabilize.

Installation / Start-up

DESCRIPTION

The Zurn Wilkins ZW209FP pilot operated pressure reducing

valve is designed for suppression systems

to reduce high inlet pressures to a safe and stable outlet

pressure. The pilot assembly reacts to changes in downstream

pressure allowing the main valve to modulate between the

closed and open position ensuring a constant downstream

set pressure. Once the downstream pressure reaches the

pilot setting, the main valve will seal shut preventing damage

downstream. Pressure regulation is not dependent upon

rate, resulting in minimal pressure loss through the valve.

In addition the ZW209FP and ZW209FPG come standard

with red epoxy coating internally and externally for corrosion

protection, as well as isolation valves and pressure gauges for

quick and easy maintenance or repair

ZW209FPTH

Threaded

Max 300 psi Inlet

®

®