1

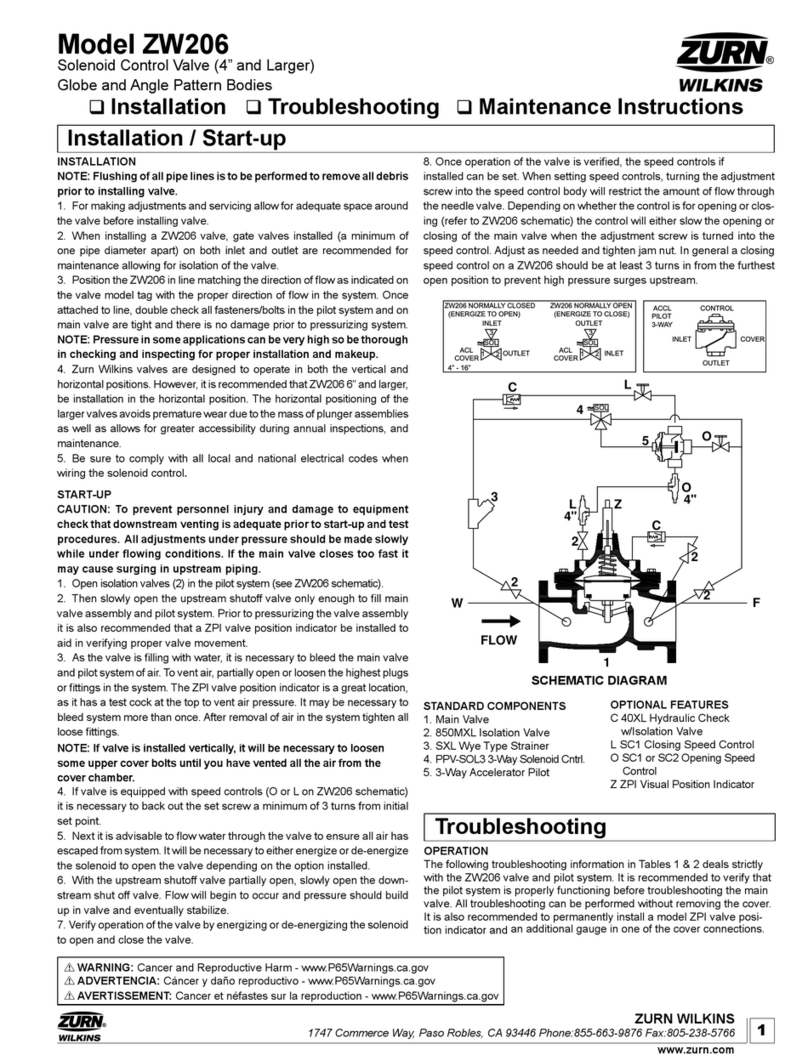

INSTALLATION

NOTE: Prior to installation of the P4000A, ensure all debris is ushed

out the piping system.

1. During the installation of a P4000A in a sprinkler system, Underwriter

Laboratories (UL) requires NFPA 13 “Standard for Installation of

Sprinkler Systems” be followed.

2. Upon installation UL also requires that the P4000A be tested in

accordance with NFPA 13. Thereafter the valve shall be inspected,

tested, and maintained in accordance to NFPA 25 “Standard for the

Inspection, Testing, and Maintenance of Water-Based Fire Protec-

tion Systems”.

3. For making adjustments and servicing allow for adequate space

around the valve.

4. Position the P4000A in line matching the direction of ow as indi-

cated on the valve model tag with the proper direction of ow in the

system. Once attached to line double check all fasteners are tight

and there is no damage prior to pressurizing system.

NOTE: Pressure in some applications can be very high so be thor-

ough in checking and inspecting for proper installation and makeup.

WARNING: Supply adequate drainage on the discharge of the P4000A.

To avoid water damage, valve must be plumbed to a safe drain.

5. Zurn Wilkins valves are designed to operate in both the vertical and

horizontal positions.

START-UP

CAUTION: To prevent personnel injury and damage to equipment check

that downstream venting is adequate prior to start-up and test proce-

dures. All adjustments under pressure should be made slowly.

Installation Start-up Maintenance Instructions

ZURN WILKINS

1747 Commerce Way, Paso Robles, CA 93446 Phone:855-663-9876 Fax:805-238-5766

1. Turn the adjustment screw clockwise until the valve spring is com-

pressed fully.

Caution: Do not over tighten the adjustment screw to prevent

damaging the valve.

2. With the inlet of the P4000A pressurized slowly turn the adjustment

screw counterclockwise until the rst sign of water ow. Either listen

carefully to the valve for water ow or look through a downstream

sight glass.

3. The valve is set to relieve pressure at the current inlet pressure at

the rst sign of water ow through the relief valve. If the desired set

pressure is different than current inlet pressure use the table below.

Turn the adjustment screw clockwise to increase set pressure or

counterclockwise to decrease set pressure. Add or subtract from the

current inlet pressure by turning the adjustment screw the number

of turns required to reach the desired set pressure based on the

adjustment table.

NOTE: The valve must be set 10 psi greater than the maximum

anticipated system pressure.

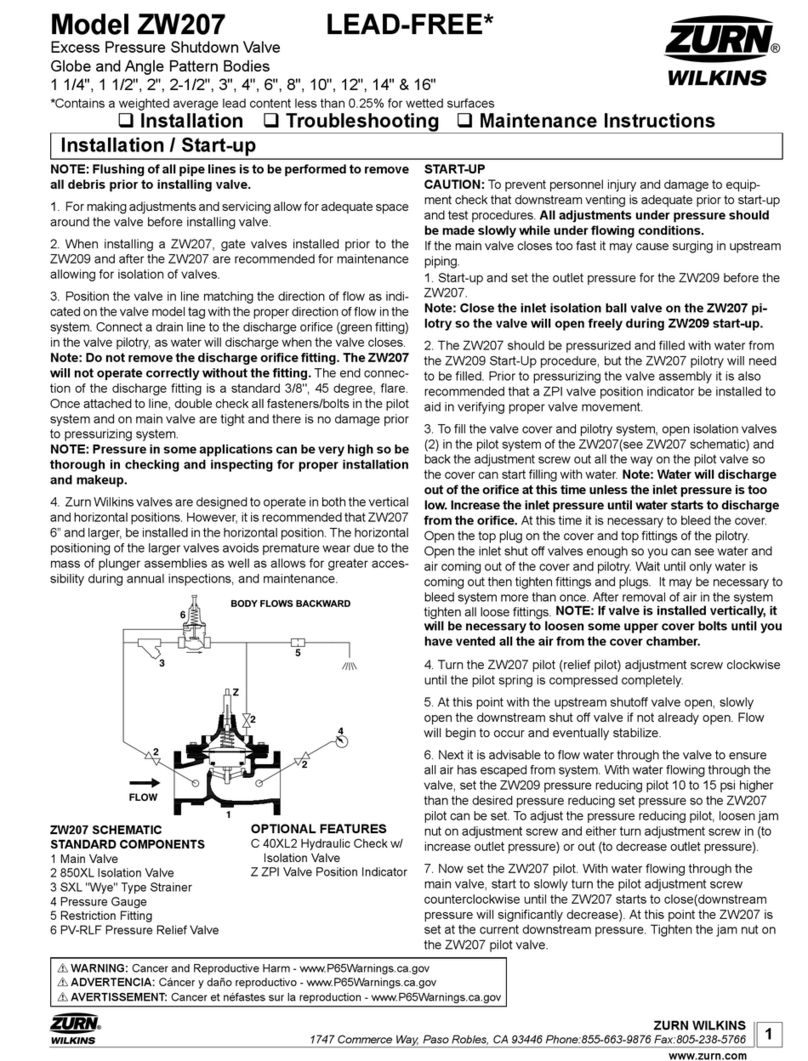

Installation / Start-up

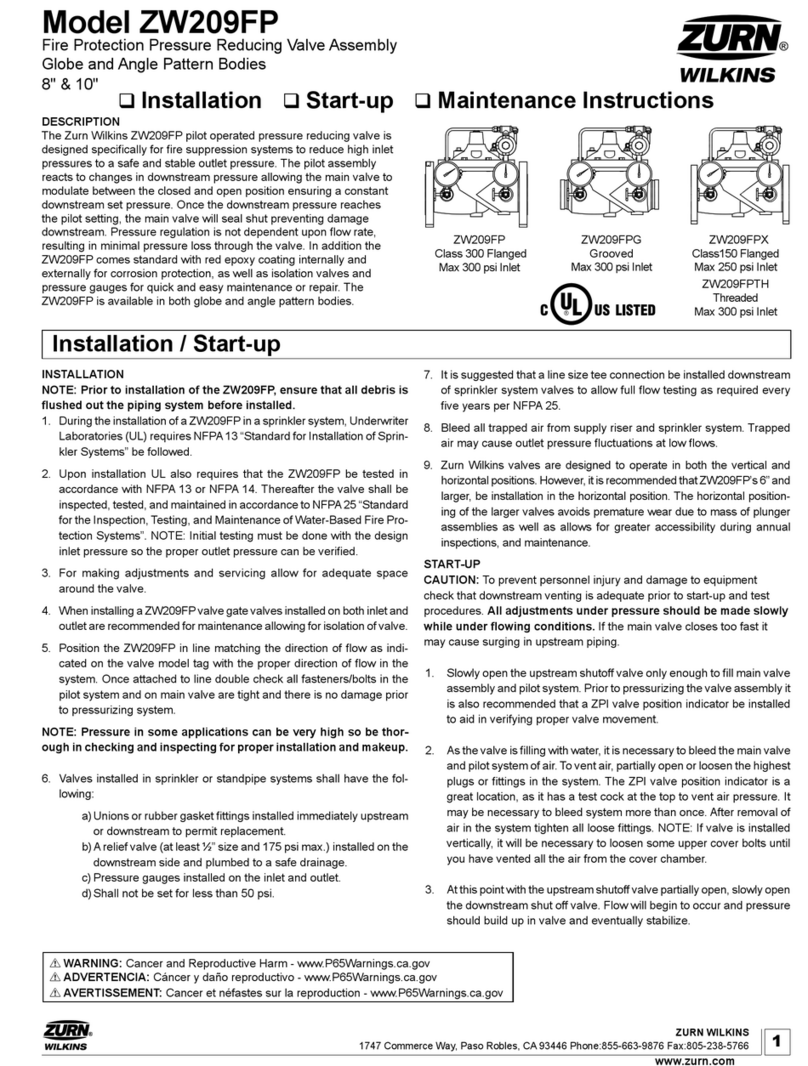

DESCRIPTION

The Zurn Wilkins P4000A Thermal Expansion Relief Valve is a direct

acting relief valve. The P4000A uses a spring to force the plunger down

upon a seat causing the valve to be normally closed. The P4000A can

be set to relieve pressures from 50 to 200 psi and the P4000AHR from

150 to 300 psi. When the inlet pressure reaches the set pressure point

it pushes up on the diaphragm which pulls the plunger off the seat. The

valve opens to relieve pressure at the inlet and allows water to ow

downstream. The P4000A opens and closes within a close pressure

range of the set pressure. All the instructions and references apply to

both models, P4000A & P4000AHR.

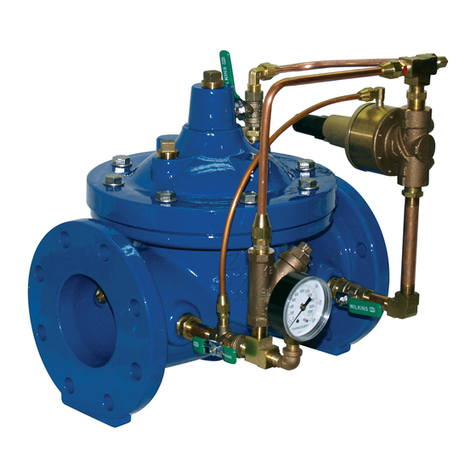

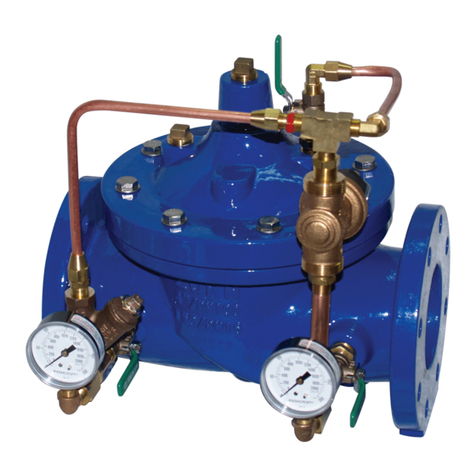

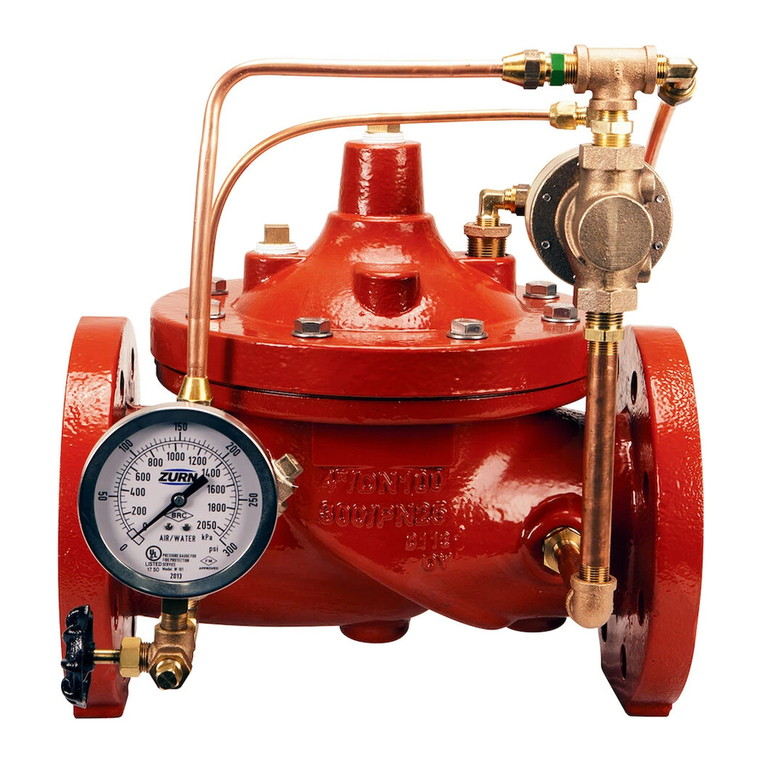

P4000A

Model P4000A & P4000AHR

Thermal Expansion Relief Valve

1/2" & 3/4"

www.zurn.com

Relief Pilot

Adjustment Range

Pressure Change per

Turn (PSI)*

50 - 200 23

150 - 300 28.5

*Note: Pressure change per turn is approximate. Use a gauge at

the inlet of P4000A to set /check relief pressure.

4. To verify proper operation of the P4000A, view the valve during

normal operation and check the valve for relief setting. Adjustments

can be made at anytime.

NOTICE: Annual inspection and maintenance is required of all plumbing system components. To ensure proper performance and

maximum life, this product must be subject to regular inspection, testing and cleaning.

P4000AHR

FM

WARRANTY: ZURN WILKINS Valves are guaranteed against defects of material or workmanship when used for the services recommended. If

in any recommended service, a defect develops due to material or workmanship, and the device is returned, freight prepaid, to ZURN WILKINS

within 12 months from date of purchase, it will be repaired or replaced free of charge. ZURN WILKINS’ liability shall be limited to our agreement

to repair or replace the valve only.

!WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov

!ADVERTENCIA: Cáncer y daño reproductivo - www.P65Warnings.ca.gov

!AVERTISSEMENT: Cancer et néfastes sur la reproduction - www.P65Warnings.ca.gov