Maintenance Instructions

7. For smaller valves (6” and below) diaphragm checks can

beperformedbyhandwiththeuseofavalvestemtool.The

valve stem tool can be made using Table 4 to create a “T” bar

handle with the appropriate threads on the opposite end of the

“T” handle.

8. To perform the diaphragm check using the vale stem tool,

rstremoveallpressureinthesystemandventthecover.Then

remove the center plug on the cover and insert tool into the top

ofthestemthreads.Oncethetoolisinserted,thevalvecanbe

liftedupandthevalvemovementcanbemeasuredbycreating

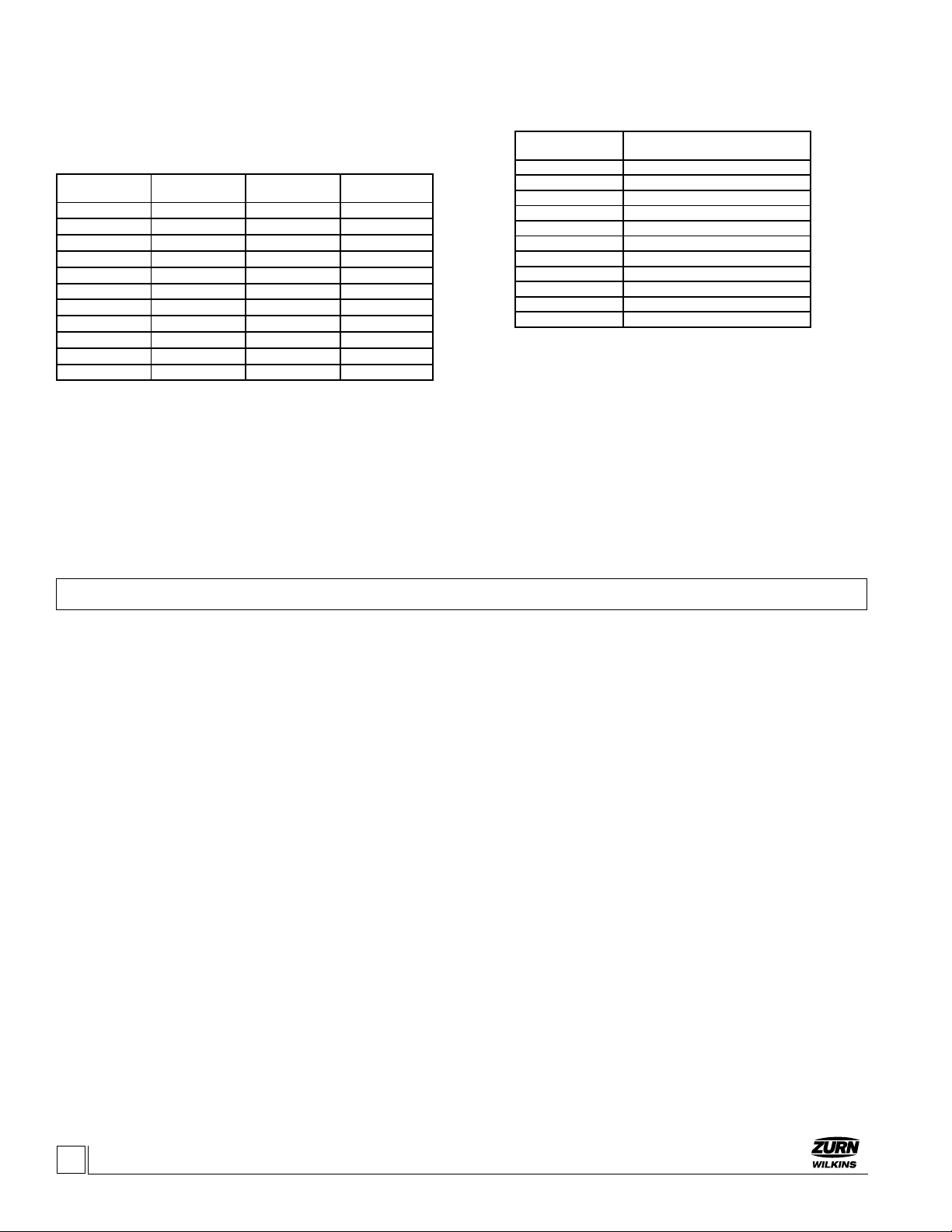

TABLE 4. VALVE STEM THREAD SIZE

SEAL CHECK

1. To check the seal of the valve disc, an additional pressure

gauge will be needed downstream of main valve.

2.Withthevalveowingslowlyclosepilotoutletballvalvesto

applypressuretocoverandallowtoclose.Ifthesolenoidop-

tionis“NormallyClosed”thesolenoidwillhavetobeenergized

toopenandallowowtocover.

3. Monitor the pressure on the inlet and installed outlet gauge.

The pressure on the outlet side should be zero. If the pressure

matches inlet pressure, the main valve is leaking or the outlet

ballvalveonthepilotsystemisallowingpressuretocreepby.

Eitherwayitisrecommendedthatthevalvebedisassembled

andinspected(referto“Disassembly”section).

PREVENTATIVE MAINTENANCE

The Zurn Wilkins ZW200 Models requires minimal mainte-

nance.However,itishighlyrecommendedtoscheduleannual

inspectionsandtohavearepairkitbeforedisassembly work

begins.

Disassembly

Warning: With the ability to perform inspections. And

maintenance without removal from the system, it is very

important that all shut off valves be closed and all pres-

sure relieved in the valve before beginning disassembly.

Failure to do so can result in personnel injury or equip-

ment damage.

1.Verifythatallpressuresourcesareclosed,upanddown-

stream of valve.

2.Removepressureinpilotsystembylooseningthetubet-

tingstothevalvebodyandcover.Whenallpressurehasbeen

vented, continue to disassemble the pilot control valve and

covertubing.NOTE:Takingapicturebeforeteardowncanhelp

withre-assemblyofpilotsystem.

3.Nextremovethecoverbylooseningandremovingthecover

bolts.Ifthecoverdoesnotcomeoffeasilyitmaybenecessary

to loosen the cover using a brass chisel and rubber mallet. Ap-

plythechiselunderthecoverpointingupwardawayfromvalve

bodyandtapbottomofcoverwiththechiselandmalletto

loosenthecover.Oncethecoverisloose,pullcoverstraightup

to avoid damaging the stem and stem bearing in the cover.

4.Withthecoverremoved,thediaphragmassemblycanbere-

moved. To avoid damaging the seat bushing, grab the stem and

lift straight up. For larger valves 8” and up it is recommended that

aneyeboltwiththeproperstemthreadsbeusedwithahoist

tolifttheassemblyoutofthevalve(seeTable3forappropriate

stem threads).

5.Nextitisrecommendedthatthediaphragmassemblybe

placedinavisewiththebottomhexnutsecured.Oncesecured

remove the spring and stem nut. While removing the nut in-

spect the stem threads. Clean stem with a wire brush if mineral

deposits or corrosion are present.

6. After inspecting the stem and removing the nut the dia-

phragmassemblycanbedismantled.Ifthevalvehasnotbeen

servicedinawhileitispossiblethattheassemblywillrequire

theuseofarubbermalletorprybarstodismantletheassem-

bly.Ifthisisthecasegentlytaporprythecomponentsuntilthe

components are free to move. When disassembling be sure to

clean,inspect,andsaveallcomponents.Replaceanydamaged

componentsasnecessary.

7. The last component to inspect is the seat which is in the

bodyofthemainvalve.Duringinspectionoftheseat,cleanand

polishasnecessarywithnegritwet/drysandpaper(400grit

orhigher).Typically,aftercleaningthereisnovisualdamageor

excessive wear the seat should not require removal. If damage

ispresentortheseatisexcessivelyworntheseatshouldbe

replaced.

8. To remove the seat, on valves 6” and smaller the seat is

threadedintothebodyandwillrequireaseatremovaltool.

Care should be taken when removing the seat to avoid damaging.

INSPECTION OF COMPONENTS

Cleaningofcomponentsisrequiredforproperinspection.Lime

depositsarecommoninsystemsthatusewater.Toremove

is not sealing due to an obstruction between the seat and the

sealoradamagedseal.Ifwaterdoesstopowingandthe

measured valve movement does not match Table 3, then there

ispossibledamageunderthecover.Removecovertoidentify

obstructionandreplacepartsasnecessary.

4ZURN WILKINS

1747CommerceWay,PasoRobles,CA93446Phone:855-663-9876Fax:805-238-5766

www.zurn.com

TABLE 3. VALVE STEM TRAVEL

VALVESIZE

(in)

VALVESIZE

(mm)

STEMTRAVEL

(in)

STEMTRAVEL

(mm)

1-1/4"-1-1/2" 38 0.4 10.2

2" 50 0.7 18.0

2-1/2" 65 0.8 21.3

3" 80 0.9 23.4

4" 100 1.1 28.8

6" 150 1.7 43.4

8" 200 2.4 59.7

10" 250 2.8 71.1

12" 300 3.4 86.4

14" 350 3.8 96.5

16" 400 4.3 109.2

marks on the tool in the opened and closed positions. Replace

orrepairanypartsasnecessary.

VALVESIZE(in) THREADSIZEUNFINTERNAL

1-1/4"-1-1/2" 10-32

2" 10-32

2-1/2" 10-32

3" 1/4-20

4" 1/4-20

6" 1/4-20

8" 3/8-16

10" 3/8-16

12" 3/8-16

14" 3/8-16

16" 3/8-16