1

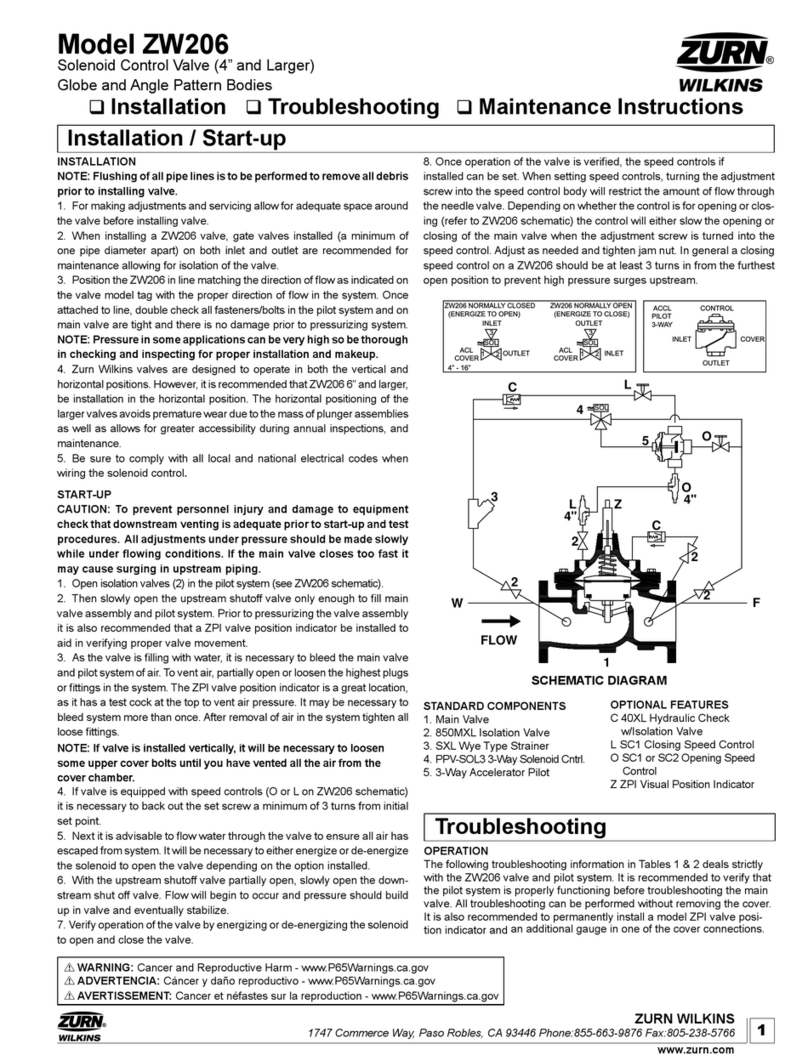

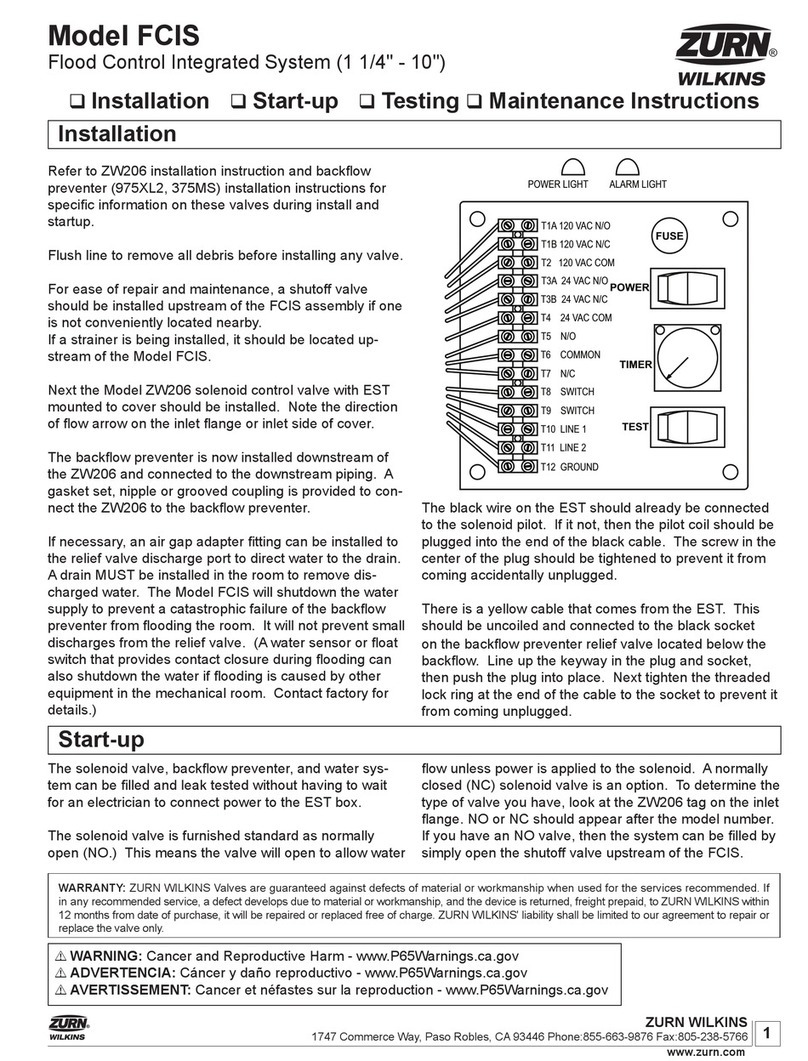

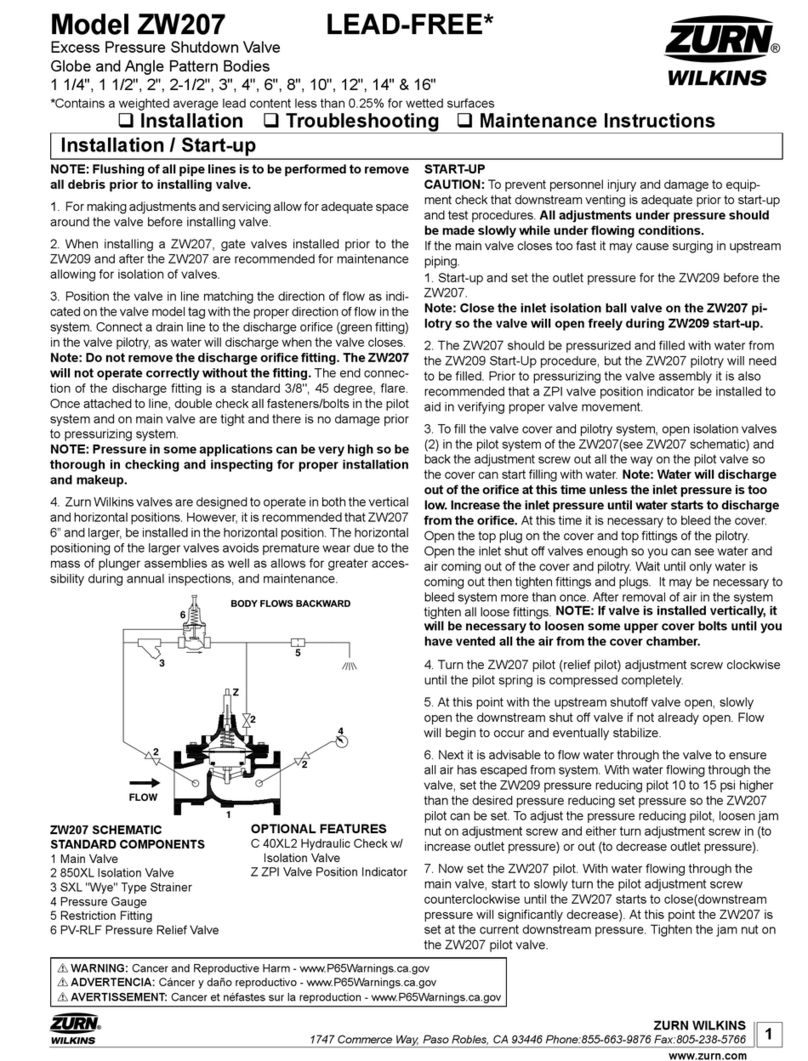

INSTALLATION

NOTE: Prior to installation of the ZW215FP, ensure that all debris

is ushed out the piping system before installed.

1. During the installation of a ZW215FP in a sprinkler system, verify

installation meets requirements of local law or the Authority Having

Jurisdiction.

2. Allow for adequate space around the valve for making adjust-

ments and servicing.

3. PositiontheZW215FPinlinematchingthedirectionofowas

indicatedonthevalvemodeltagwiththeproperdirectionofowin

the system. The valve must be installed on the discharge side of the

repump.

4. Connect pilot control sensing connection to the suction side of

the pump by minimum 3/8 in diameter tubing.

5. Once control valve and sensing line are installed, double check

all fasteners/bolts in the pilot system and on main valve are tight and

there is no damage prior to pressurizing system.

NOTE: Pressure in some applications can be very high so be

thorough in checking and inspecting for proper installation and

makeup.

6. Zurn Wilkins valves are designed to operate in both the vertical

and horizontal positions. However, it is recommended that ZW215FP’s

6” and larger, be installation in the horizontal position. The horizontal

positioning of the larger valves avoids premature wear due to mass of

plunger assemblies as well as allows for greater accessibility during

annual inspections, and maintenance.

START-UP

CAUTION: To prevent personnel injury and damage to equip-

ment check that downstream venting is adequate prior to

start-up and test procedures. All adjustments under pressure

should be made slowly. If the main valve opens or closes too fast

it may cause surging in upstream piping.

Installation Start-up Maintenance Instructions

Model ZW215FP

Fire Pump Suction Control Valve

Globe and Angle Pattern Bodies

2", 2-1/2", 3", 4", 6", 8", & 10"

ZW215FP

Class 150 Flanged

Max 250 psi Inlet

ZW215FPG

Grooved

Max 300 psi Inlet

ZW215FPY

Class 300 Flanged

Max 300 psi Inlet

1. Pressurize the upstream side of the ZW215FP.

2. Asthevalveisllingwithwater,itisnecessarytobleedthemain

valve and pilot system of air. To vent air, partially open or loosen the

highestplugsorttingsinthesystem.TheZPIvalvepositionindicator

is a great location, as it has a test cock at the top to vent air pressure.

It may be necessary to bleed system more than once. After removal of

airinthesystemtightenallloosettings.NOTE: If valve is installed

vertically, it will be necessary to loosen some upper cover bolts

until you have vented all the air from the cover chamber.

3. Install a pressure gauge on the suction side of the pump or install

a gauge in the test cock on the sensing line to read the suction pres-

sure.

4. Loosen the pilot adjustment screw until the adjustment screw

can be turned by hand. Note: A small amount of spring force must

be maintained so the spring and spring discs do not fall out of

alignment. Do not loosen the pilot adjustment screw completely.

Note: The control valve should open and allow a lot of water to

ow. If there is no ow, continue turning the pilot adjustment screw

counterclockwise.Oncewaterisowingthroughthecontrolvalveit

is necessary to lower the suction pressure below the desire set pres-

sure. One can cause the suction pressure to decrease by increasing

owthroughthepumporusingavalveupstreamofthepumpsuction

to throttle water to the pump.

5. Once suction pressure is below desired minimum suction pres-

sure, slowly turn the pilot valve adjustment screw clockwise. As the

screw is tightened the control valve will slowly start to close causing

upstream pressure to increase. Continue turning adjustment screw

clockwise until suction pressure is stable at the desired set pressure.

6. Tighten adjustment screw jam nut once step 4 is completed. To

verify proper operation of the ZW215FP, view the valve during normal

operation and check the valve for minimum suction pressure setting.

Adjustments can be made at anytime.

Installation / Start-up

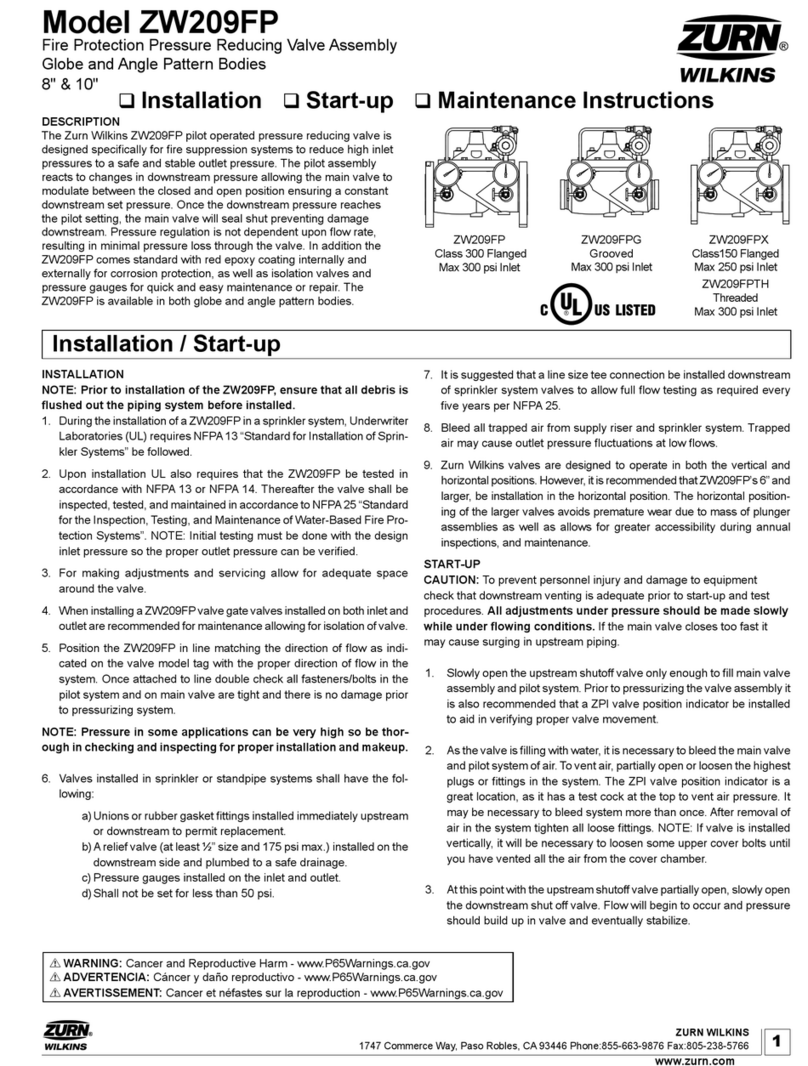

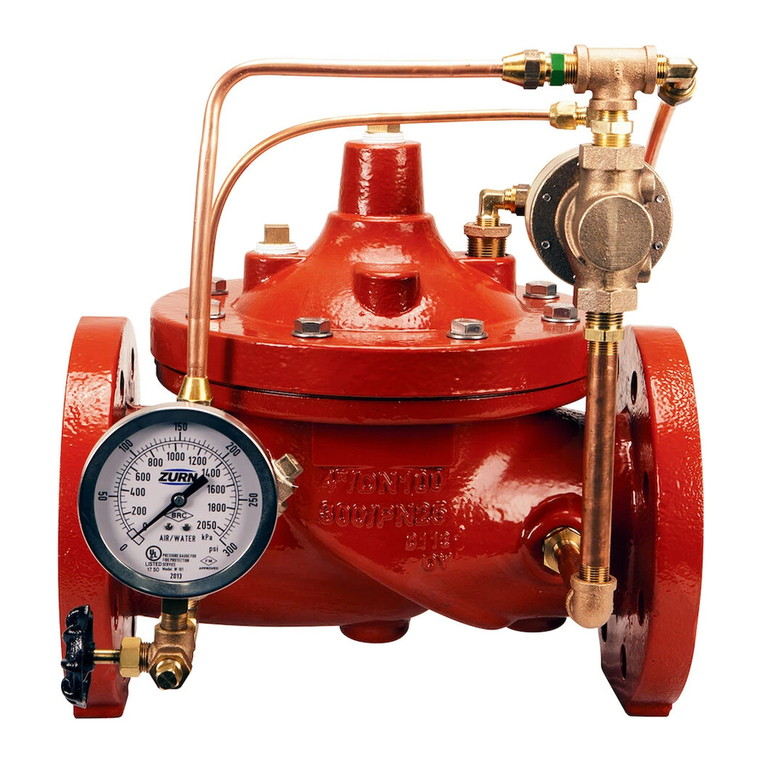

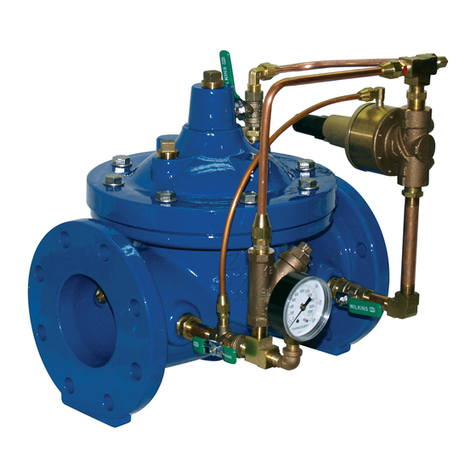

DESCRIPTION

The Zurn Wilkins Model ZW215FP Fire Pump Suction Control Valve

isdesignedspecicallyforFireSuppressionSystemstopreventre

pumps from over-drawing from the water supply resulting in damage

to the pump or the supply network because of very low or negative

pressuresonthesuctionsideoftherepump.Thepilotassembly

reacts quickly to increases and decreases of suction pressure.

The control valve will close if suction pressure drops below the set

pressure. The control valve will open again once suction pressure

rises to the control valve set pressure and will modulate to keep

the suction pressure at the set pressure until supply increases. In

addition the Model ZW215FP comes standard with red epoxy coat-

ing internally and externally for corrosion protection, as well as a

test cock on the sensing port for quick bleeding of sensing line. The

ZW215FP is available in both globe and angle pattern bodies.

ZW215FPTH

Threaded

Max 300 psi Inlet

ZURN WILKINS

1747 Commerce Way, Paso Robles, CA 93446 Phone:855-663-9876 Fax:805-238-5766

www.zurn.com

FM

APPROVED

!WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov

!ADVERTENCIA: Cáncer y daño reproductivo - www.P65Warnings.ca.gov

!AVERTISSEMENT: Cancer et néfastes sur la reproduction - www.P65Warnings.ca.gov