1

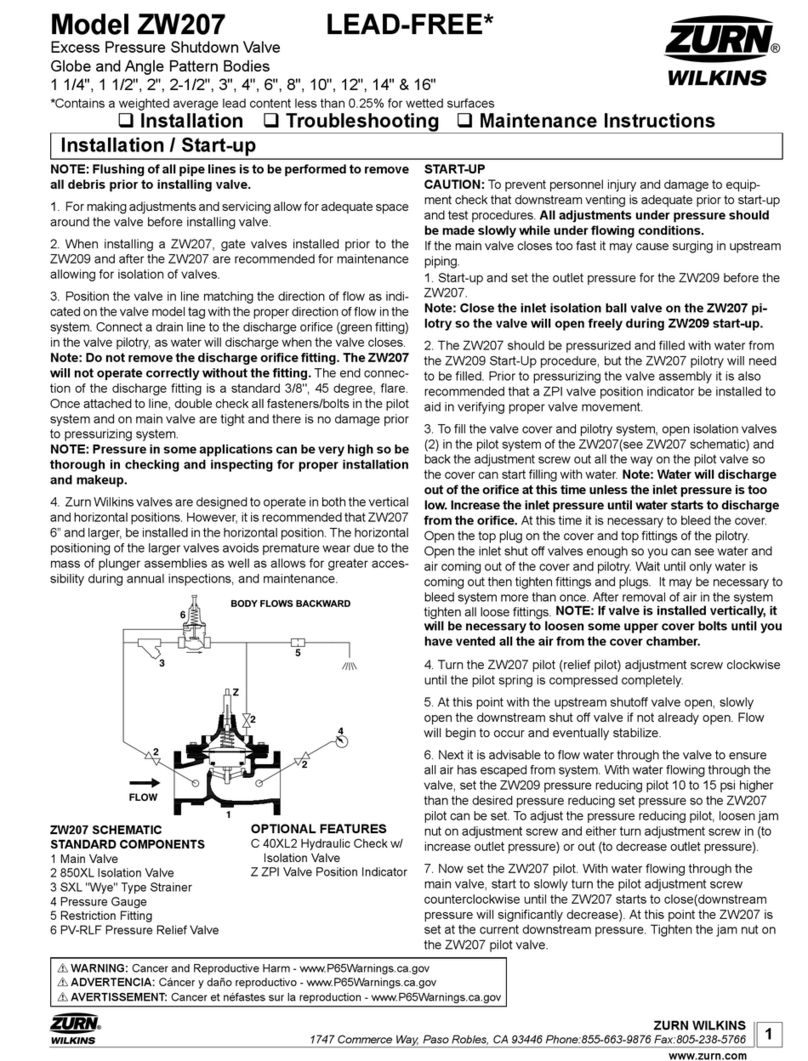

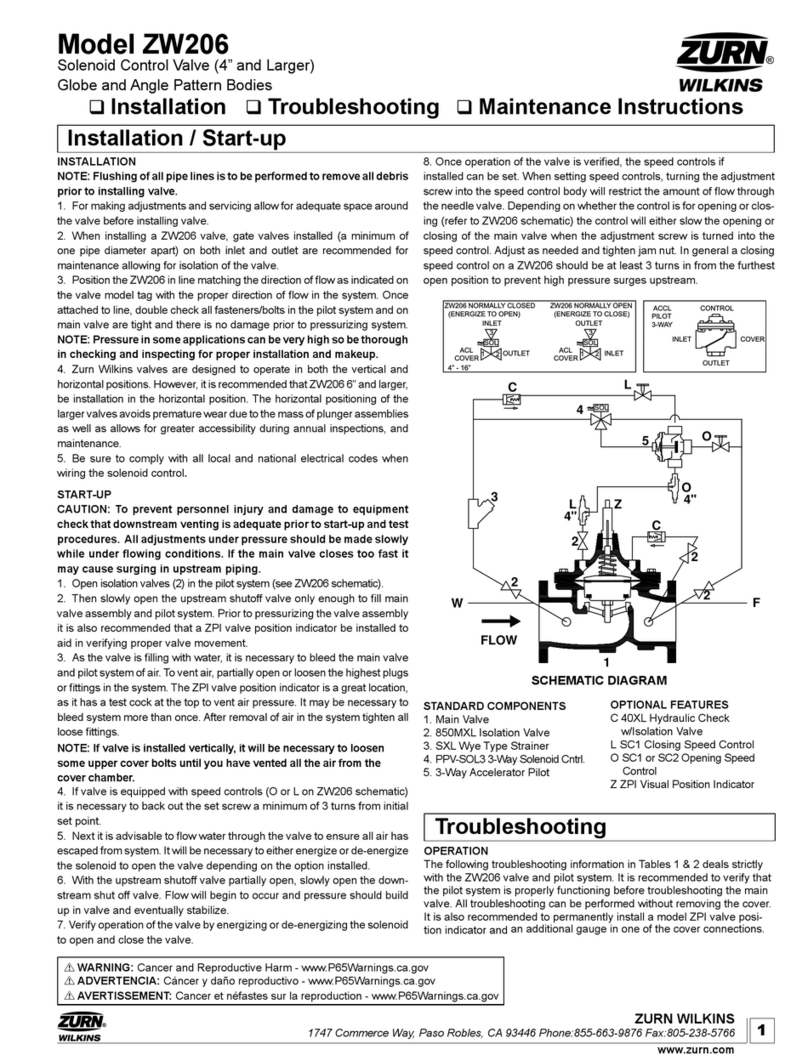

INSTALLATION

NOTE: Prior to installation of the P4000A, ensure all debris

is ushed out the piping system.

1. During the installation of a P4000A in a sprinkler system, Under-

writer Laboratories (UL) requires NFPA 13 “Standard for Installation

of Sprinkler Systems” be followed.

2. Upon installation UL also requires that the P4000A be tested in

accordance with NFPA 13. Thereafter the valve shall be inspected,

tested, and maintained in accordance to NFPA 25 “Standard for

the Inspection, Testing, and Maintenance of Water-Based Fire

Protection Systems”.

3. For making adjustments and servicing allow for adequate

space around the valve.

4. PositiontheP4000Ainlinematchingthedirectionofowas

indicatedonthevalvemodeltagwiththeproperdirectionofow

in the system. Once attached to line double check all fasteners

are tight and there is no damage prior to pressurizing system.

NOTE: Pressure in some applications can be very high so be

thorough in checking and inspecting for proper installation

and makeup.

WARNING: Supply adequate drainage on the discharge of

the P4000A. To avoid water damage, valve must be plumbed

to a safe drain.

5. Zurn Wilkins valves are designed to operate in both the verti-

cal and horizontal positions.

START-UP

CAUTION: To prevent personnel injury and damage to equip-

ment check that downstream venting is adequate prior to

start-up and test procedures. All adjustments under pressure

should be made slowly.

Installation Start-up Maintenance Instructions

ZURN WILKINS

1747 Commerce Way, Paso Robles, CA 93446 Phone:855-663-9876 Fax:805-238-5766

®

1. Turn the adjustment screw clockwise until the valve spring

is compressed fully.

Caution: Do not over tighten the adjustment screw to pre-

vent damaging the valve.

2. With the inlet of the P4000A pressurized slowly turn the

adjustmentscrewcounterclockwiseuntiltherstsignofwater

ow.Eitherlistencarefullytothevalveforwateroworlook

through a downstream sight glass.

3. The valve is set to relieve pressure at the current inlet

pressureattherstsignofwaterowthroughthereliefvalve.If

the desired set pressure is different than current inlet pressure

use the table below. Turn the adjustment screw clockwise to

increase set pressure or counterclockwise to decrease set pres-

sure. Add or subtract from the current inlet pressure by turning

the adjustment screw the number of turns required to reach the

desired set pressure based on the adjustment table.

Note: The valve must be set 10 psi greater than the maxi-

mum anticipated system pressure.

Installation / Start-up

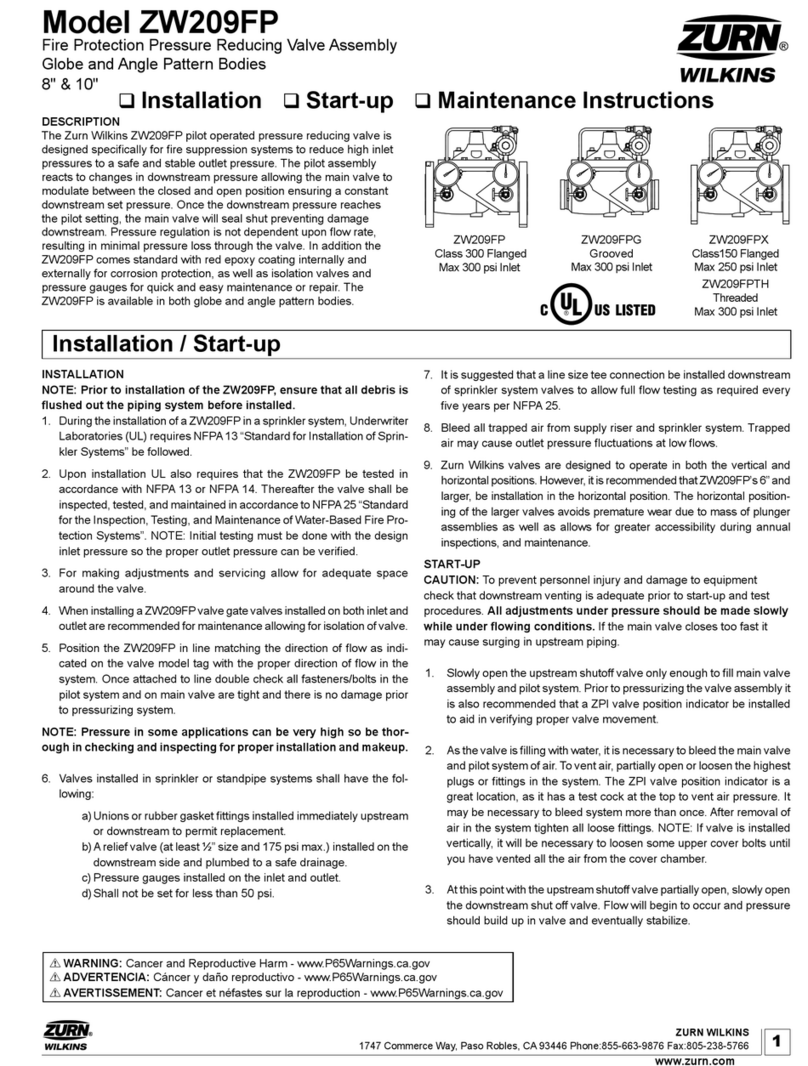

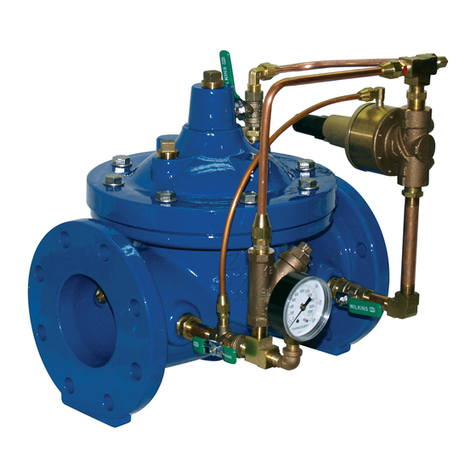

DESCRIPTION

TheZurnWilkinsP4000AThermalExpansionReliefValveis

a direct acting relief valve. The P4000A uses a spring to force

the plunger down upon a seat causing the valve to be normally

closed. The P4000A can be set to relieve pressures from 50

to200psiandtheP4000AHRfrom150to300psi.Whenthe

inlet pressure reaches the set pressure point it pushes up on

the diaphragm which pulls the plunger off the seat. The valve

openstorelievepressureattheinletandallowswatertoow

downstream. The P4000A opens and closes within a close

pressure range of the set pressure.

All the instructions and references apply to both models, P4000A

&P4000AHR. P4000A

®

Model P4000A & P4000AHR

ThermalExpansionReliefValve

1/2" & 3/4"

www.zurn.com

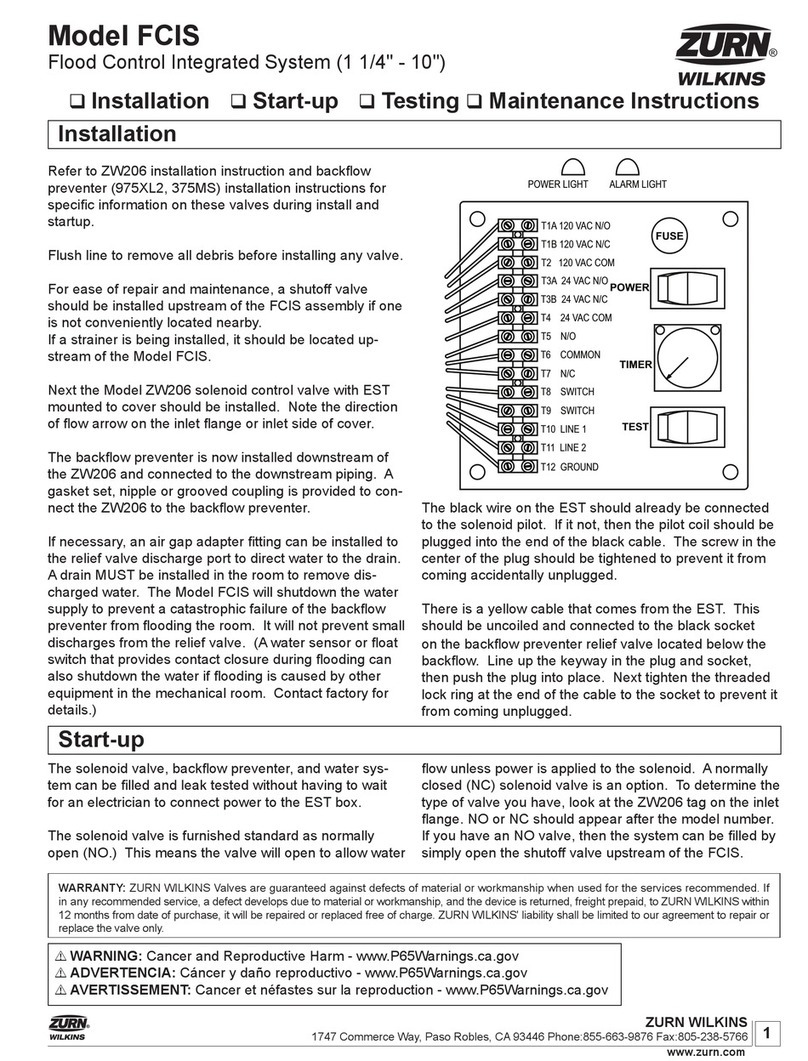

ReliefPilot

AdjustmentRange

Pressure Change per

Turn (PSI)*

50 - 200 23

150 - 300 28.5

*Note: Pressure change per turn is approximate. Use a

gauge at the inlet of P4000A to set /check relief pressure.

4. To verify proper operation of the P4000A, view the valve

during normal operation and check the valve for relief setting.

Adjustments can be made at anytime.

NOTICE: Annual inspection and maintenance is required of all plumbing system components. To ensure proper perfor-

mance and maximum life, this product must be subject to regular inspection, testing and cleaning.

P4000AHR

FM