Testing Procedures

ZURN WILKINS

1747 Commerce Way, Paso Robles, CA 93446 Phone:855-663-9876 Fax:805-238-5766

2

www.zurn.com

The timer has a range up to 10 minutes, but comes from

the factory set for a 1 second to 60 second range. When

it leaves the factory, the indicator of the timer should be

pointing directly to the left for a 10 second delay.

Turn the POWER switch on. The green power light on

top of the box will light.

If the backow is not pressurized, the monitor switch will

start the timer. If the backow is pressurized, manually

start the timer by pushing and holding the TEST switch

below the timer. A green light on the front of the timer

should come on when it is triggered. You can start count-

ing or use a stopwatch to check the timer adjustment. A

red light on the front of the timer and on top of the box

will come on when the timer reaches the end. The so-

lenoid coil will also click and hum if it is a normally open

valve. On a normally closed valve, the humming will

stop; a click may not be audible. (When the timer is reset

and the power turned back on, the normally closed valve

should click.) If this time delay does not match your re-

quirements, turn the knob and repeat this test. The timer

is reset by turning the power switch off and back on.

(Note: the coil will become hot while it is powered.)

Fill the system slowly to prevent water hammer, and then

vent any trapped air from the system.

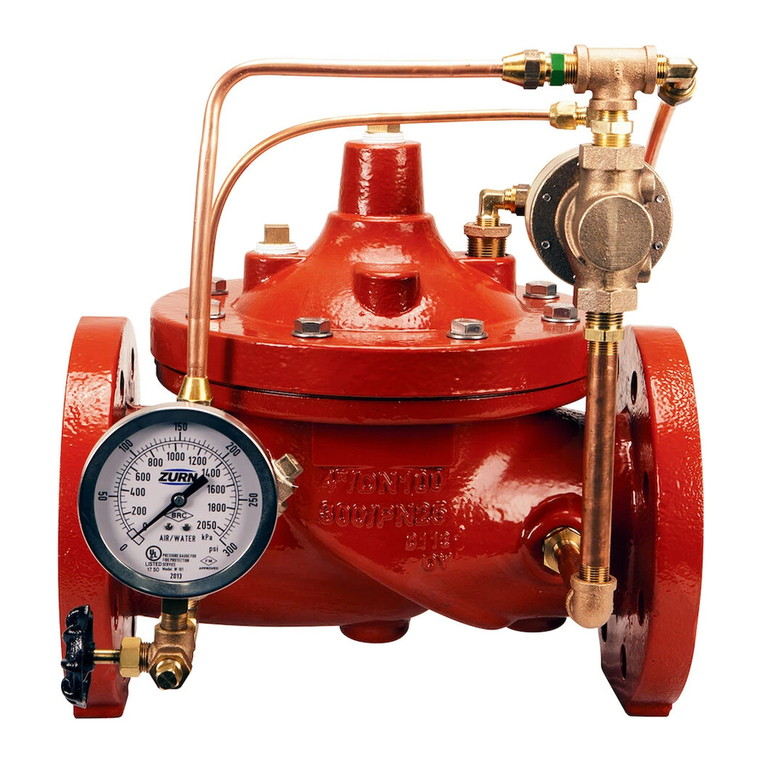

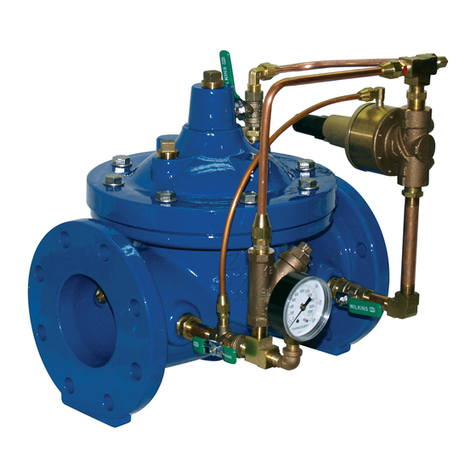

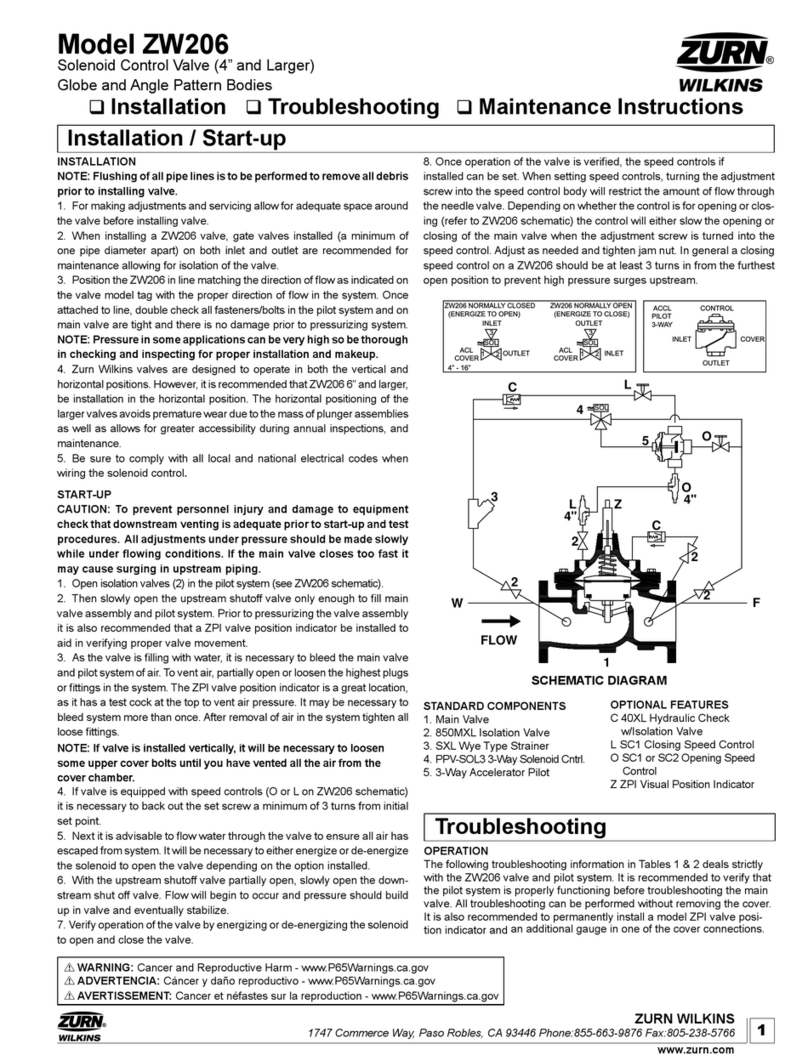

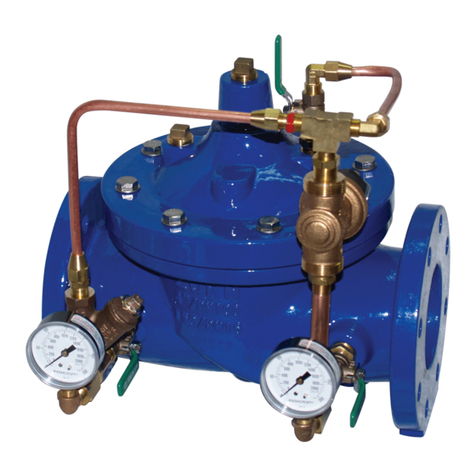

The solenoid valve cover must be vented of air for proper

operation; refer to ZW206 instruction sheet.

There is a red knob on the solenoid pilot. This will al-

low the pilot valve of a NO or NC valve to be operated

without power. If your valve is NC, then the solenoid

control valve will prevent water from lling the backow

preventer. Turn the red knob on the solenoid pilot to

manually open the valve and ll the system with water.

If the manual operator has been used on the solenoid

pilot, make sure that it is returned to unscrewed position

for the FCIS to operated properly.

If left for an extended duration in manual override, it

may be wise to hang a note pointing this out to others

who may continue the system startup and testing.

A ½” plugged conduit knockout is located on the bottom

of the EST near the cables. The plug can be removed

to allow 120 VAC power to be connected to terminals

T10, T11 and T12 in the box. Once the power has been

connected to the EST, then proceed to the Testing sec-

tion.

Start-up

DANGER!

Death or injury can result if safety precautions are not

followed. There are 120VAC wires and connections lo-

cated inside the EST box. Only properly trained person-

nel should work near these connections. If all wires are

installed properly, there should be no risk of contact with

energized components. Care should still be exercised.

Do not use any screwdrivers or other un-insulated metal

objects inside the box when the power wires in the box

are energized.

There are three user controls inside the EST box. A

power switch, a delay timer knob and a test switch.

Open the EST box to access these controls.

SET TIMER DELAY

The timer is provided so that nuisance relief valve dis-

charges due to water hammer will not cause the system

to shutdown. It should be set so it is long enough for the

valve to re-close if it opens for pressure uctuations. If

it is set too long, then more discharge will occur before

shutdown starts.