Model ZW209H LEAD-FREE*

Pressure Reducing and Pressure Sustaining Valve

Globe and Angle Pattern Bodies

1 1/4", 1 1/2", 2", 2-1/2", 3", 4", 6", 8", 10", 12", 14" & 16"

*Contains a weighted average lead content less than 0.25% for wetted surfaces

NOTE: Flushing of all pipe lines is to be performed to remove

all debris prior to installing valve.

NOTE: If installation is subject to very low ow or potentially

static conditions it is recommended a pressure relief valve

(1/2" minimum) be installed downstream of the pressure

reducing valve for additional system protection.

1. For making adjustments and servicing allow for adequate space

around the valve before installing valve.

2. When installing a ZW209H, gate valves installed on both inlet

and outlet are recommended for maintenance allowing for isolation

of valve.

3.Position the valve in line matching the direction of ow as

indicatedonthevalvemodeltagwiththeproperdirectionofow

in the system. Once attached to line, double check all fasteners/

bolts in the pilot system and on main valve are tight and there is

no damage prior to pressurizing system.

NOTE: Pressure in some applications can be very high so be

thorough in checking and inspecting for proper installation

and makeup.

4. Zurn Wilkins valves are designed to operate in both the verti-

cal and horizontal positions. However, it is recommended that

ZW209H 6” and larger, be installed in the horizontal position. The

horizontal positioning of the larger valves avoids premature wear

due to the mass of plunger assemblies as well as allows for greater

accessibility during annual inspections, and maintenance.

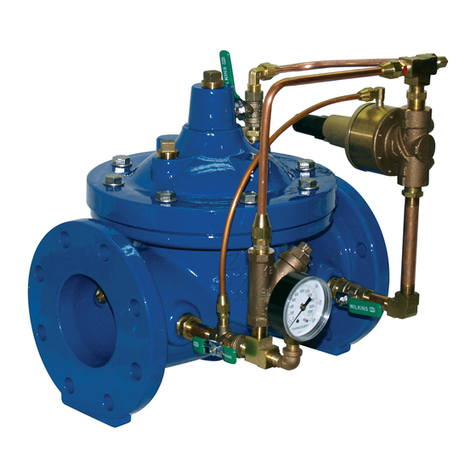

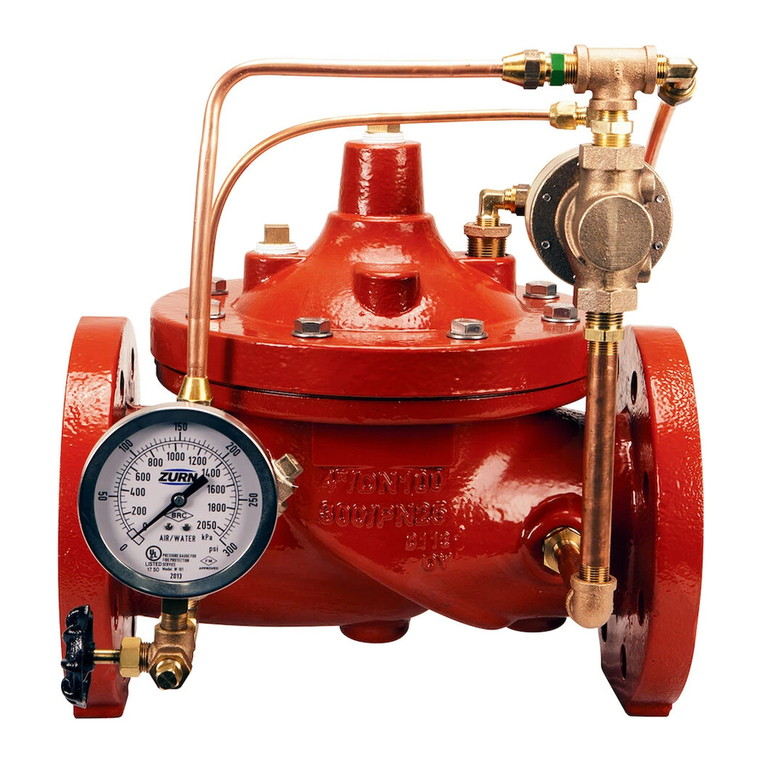

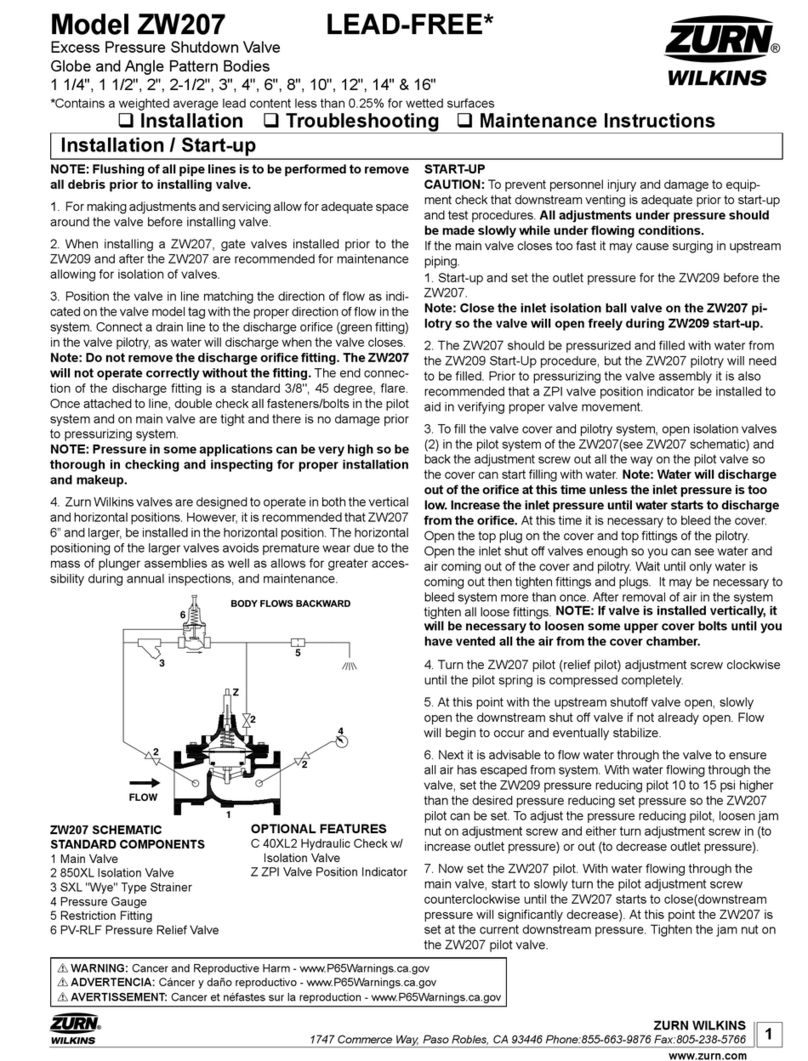

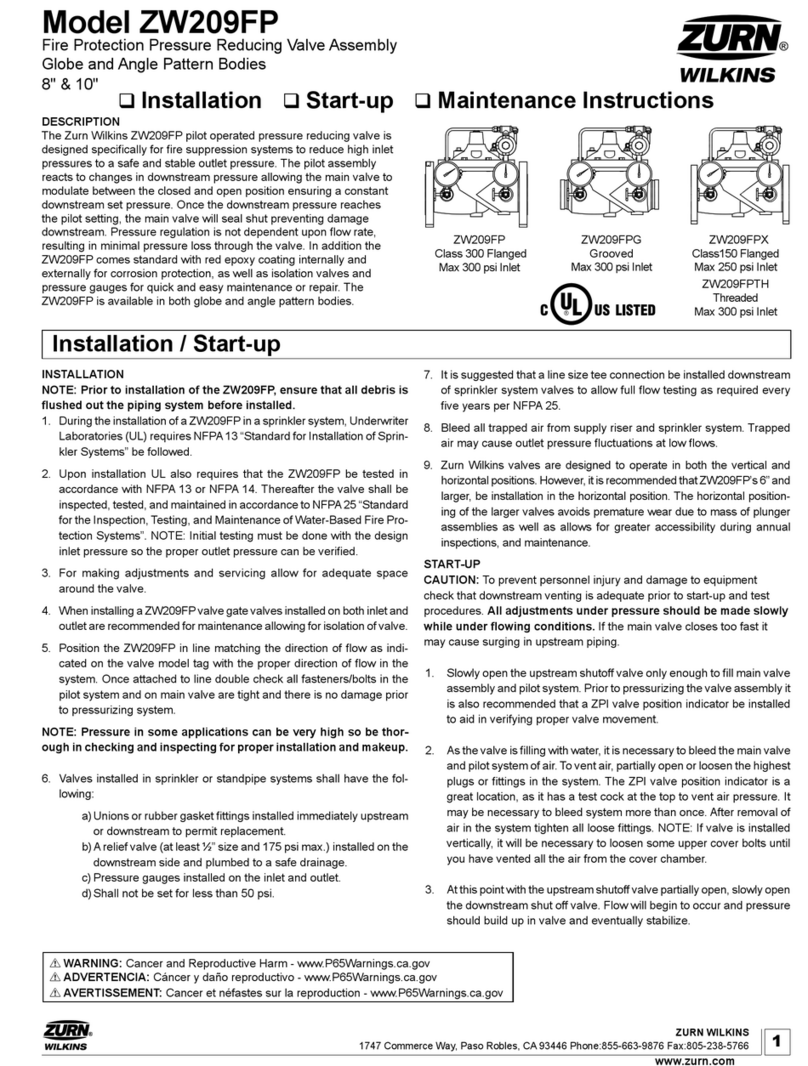

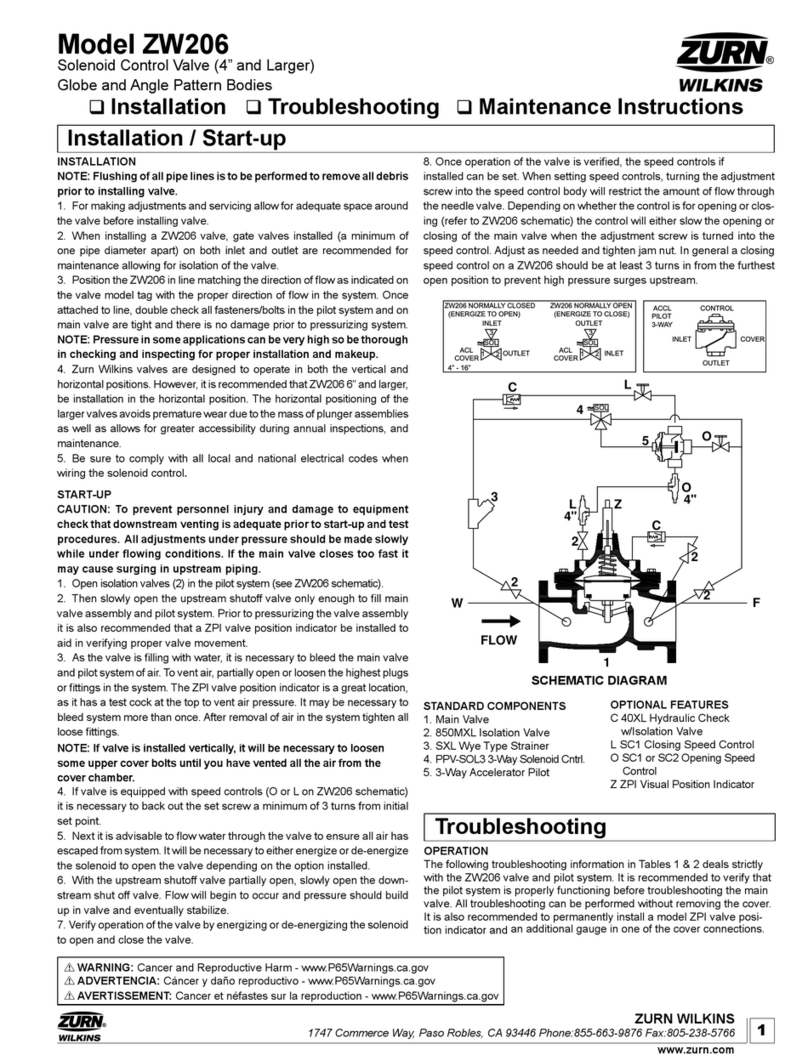

ZW209H SCHEMATIC

STANDARD COMPONENTS

1 Main Valve

2 850MXL Isolation Valve

3 SXL Wye Type Strainer

4 Pressure Gauge

5 Restriction Tube Fitting

6 PRXLPressure Reducing Control

7 PV-RLF Pressure Relief Valve

OPTIONAL FEATURES

C 40XL2 Hydraulic Check w/

Isolation Valve

L SC1 Closing Speed Control

O SC1 Opening Speed Control

Z ZPI Valve Position Indicator

Prior to pressurizing the valve assembly it is also recommended

that a ZPI valve position indicator be installed to aid in verifying

proper valve movement.

3.Asthevalveisllingwithwater,itisnecessarytobleedthe

main valve and pilot system of air. To vent air, partially open or

loosenthehighestplugsorttingsinthesystem.TheZPIvalve

position indicator is a great location, as it has a test cock at the

top to vent air pressure. It may be necessary to bleed system

more than once. After removal of air in the system tighten all

loosettings.NOTE: If valve is installed vertically, it will be

necessary to loosen some upper cover bolts until you have

vented all the air from the cover chamber.

4. Before setting valve, if valve is equipped with SC1 Flow con-

trols (O or L on ZW209H schematic) it is necessary to back out

the set screw a minimum of 3 turns from initial set point.

5. Turn the relief pilot adjustment screw counterclockwise until

the screw starts to spin freely to lower the relief pressure so the

pressurereducingpilotcanbesetrst.

6. At this point with the upstream shutoff valve partially open,

slowly open the downstream shut off valve. Flow will begin to

occur and pressure should build up in valve and eventually

stabilize.

7.Nextitisadvisabletoowwaterthroughthevalvetoensure

allairhasescapedfromsystem.Withwaterowingthroughthe

valve the Zurn Wilkins PRV pilot can be set to the desired pres-

sure. To adjust the pressure reducing pilot, loosen jam nut on ad-

justment screw and either turn adjustment screw in (to increase

outlet pressure) or out (to decrease outlet pressure). Tighten jam

nut on pilot when the desired setting has been made.

8. To verify proper operation of ZW209H close and open down-

stream shut off valve several times to ensure downstream pres-

sure is stable at set pressure.

9. Next the relief/sustaining pilot must be set at the desired

sustainingpressure.Withwaterstillowingthroughthemain

valveusetheupstreamisolationvalvetothrottlewaterowinto

the ZW209H. Close the upstream isolation valve until the inlet

pressure at the ZW209H is below the desired sustaining set

pressure.

10.WithwaterowingthroughtheZW209Hstarttoturnthe

relief/sustaining pilot adjustment screw clockwise until the valve

starts to modulate and the inlet pressure starts to increase.

Continue turning the adjustment screw clockwise until the inlet

pressure is at the desired set pressure.

11. If the inlet pressure cannot be adjusted lower than the

desired set relief/sustaining pressure then set the relief valve

by turning the adjustment screw clockwise until the spring is

fully compressed. The control valve will close. Next, slowly

turn the adjustment screw counterclockwise until water starts

toowthroughthecontrolvalve.Nowthereliefvalveissetto

the current inlet pressure. Use the table on the next page to set

the relief pressure at a different pressure than the current inlet

pressure. Turn the adjustment screw clockwise to increase set

pressure or counterclockwise to decrease set pressure. Add or

subtract from the current inlet pressure by turning the adjustment

screw the number of turns required to reach the desired set

pressure based on the adjustment table.

START-UP

CAUTION: To prevent personnel injury and damage to equipment

check that downstream venting is adequate prior to start-up

and test procedures. All adjustments under pressure should

be made slowly while under owing conditions. If the main

valve closes too fast it may cause surging in upstream piping.

1. Open isolation valves (2) in the pilot system (see ZW209H

schematic).

2. Then slowly open the upstream shutoff valve only enough to

llmainvalveassemblyandpilotsystem.

Installation / Start-up

ZURN WILKINS

1747 Commerce Way, Paso Robles, CA 93446 Phone:855-663-9876 Fax:805-238-5766 1

www.zurn.com

®

®

Installation Troubleshooting Maintenance Instructions