WILKINS, a ZURN company

1747 Commerce Way, Paso Robles, CA 93446 Phone:805-238-7100 Fax:805-238-5766

Model PV-PRD

Pressure Reducing Valve

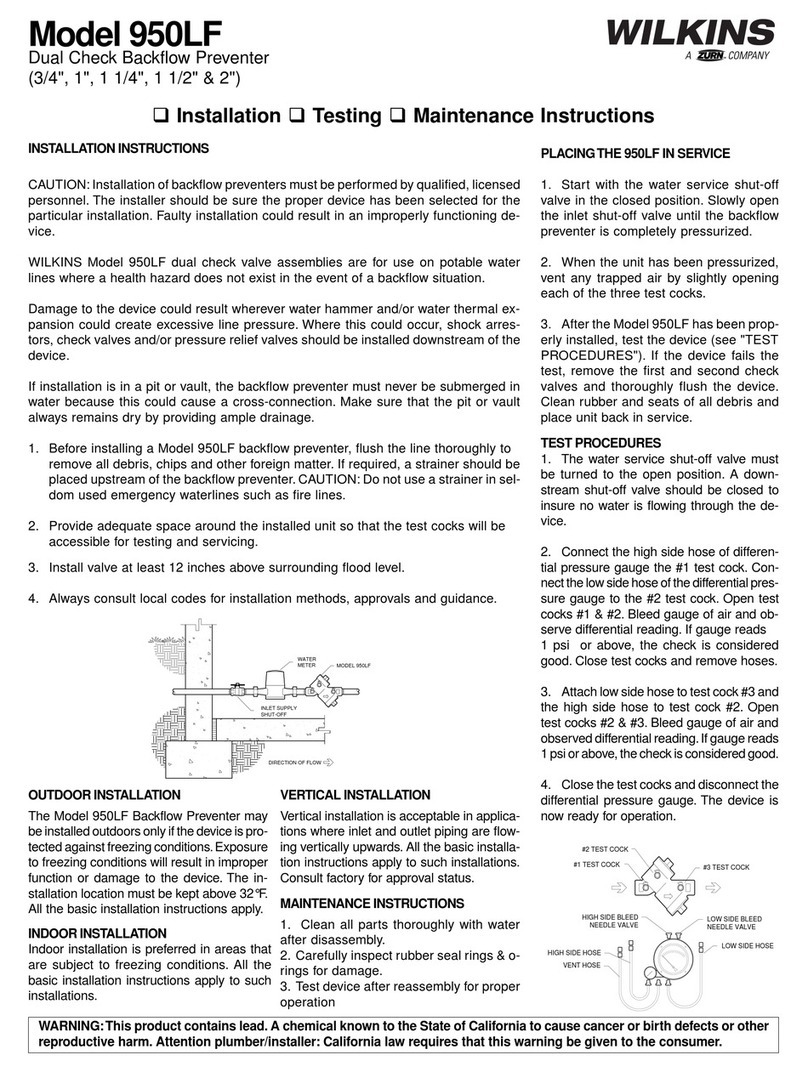

The PV-PRD Pressure Reducing Valve may be installed

in any position. There is one inlet port and two outlets, for

either straight or angled installation. A ow arrow is marked

on the body and should be oriented as needed.

DISASSEMBLY

Prior to disassembly, relieve all pressure in pilot system

and then remove the PV-PRD.

1. Secure valve body and remove main cap on bottom

of valve using an adjustable wrench.

2. Use a 13 mm socket to remove the plunger.

3. Next remove adjustment cover (plastic cover), 3/8”

adjustment bolt with nut, 8 socket head screws

around the pilot bell using a 5/32" hex key, spring,

and spring disc.

4. At this point the PRV stem yoke is free to move and

can be removed from the valve body.

5. Continue to remove the 5/16" diaphragm nut, lock

washer, and diaphragm retainer.

6. After completely disassembling, thoroughly clean and

inspect all components before reassembly. Replace

any parts as necessary after inspection.

7. The pilot seat generally does not need to be removed,

but it can be removed with a 1/2" socket, if required.

REASSEMBLY

Reassembly of the PV-PRD is the reverse of disassembly.

1. Install the new o-ring on top of pilot yoke threads follo-

wed by new diaphragm and diaphragm disc.

Then place lock washer over pilot yoke stem along

with the 5/16" diaphragm nut and tighten. Diaphragm

bolt holes must be centered on yoke legs.

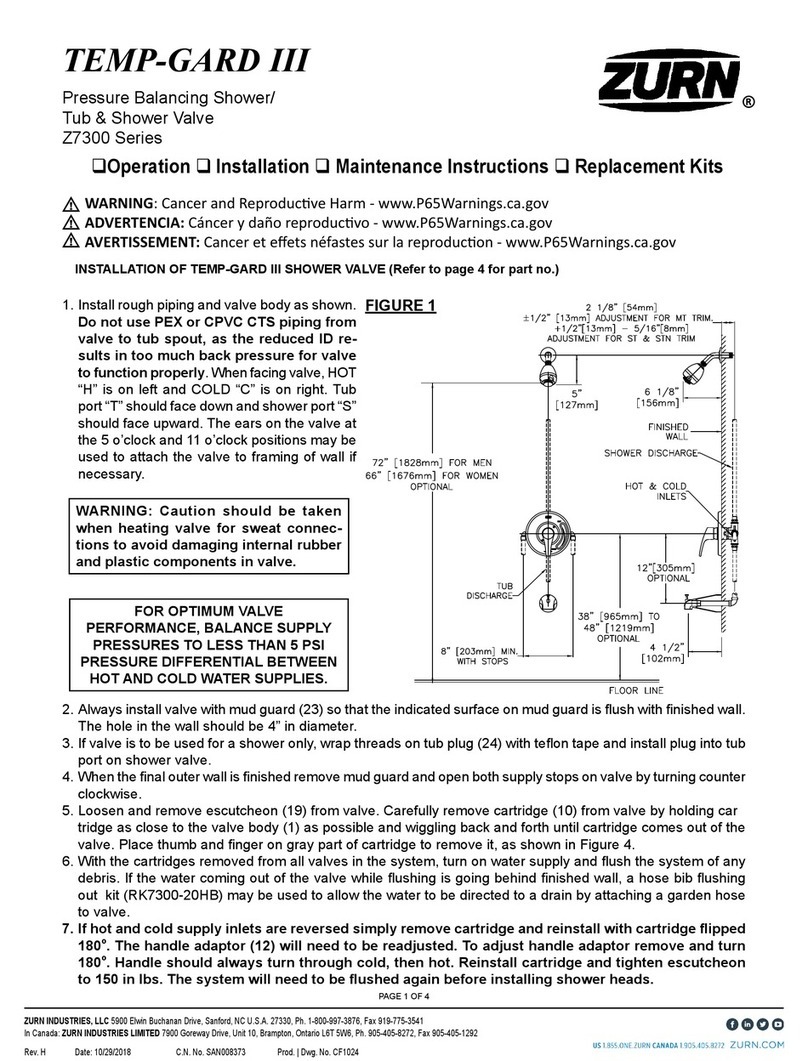

See following diagram:

3. Then attach plunger to the bottom of the pilot yoke via

the main cap hole and tighten with a 13 mm socket.

4. Install main cap in bottom of valve body with new

o-ring.

5. Install spring, spring disc, and pilot bell on the valve

body.

6. Insert socket head cap screws into pilot bell holes

and thread into valve body. Tighten all screws in a

cross pattern.

7. Install adjusting screw by hand with jam nut. Set valve

once reinstalled into main valve pilot system.

8. While owing water as shown in Table 1, adjust the

Wilkins PV-PRD control to desired pressure if installed

on an ACV. To change pressure setting, turn the

adjusting screw clockwise to increase pressure,

counterclockwise to decrease pressure. There must

be liquid owing through the valve during pressure

adjustments. When the desired setting has been

made, tighten jam nut.

9. For further assistance or ordering replacement parts go

to www.zurn.com or call product support 877-222-5356.

Table 1

CENTER YOKE LEGS

BETWEEN

DIAPHRAGM HOLES

2. Next carefully slide yoke assembly into body and

around pilot seat.

NOTE: Line up diaphragm screw holes with holes

in body. Move yoke up and down checking for yoke

contacting or dragging on valve body.

VALVE

SIZE

inches 2 1/2 3 4 6

mm 65 80 100 150

MINIMUM FLOW RATES TO SET VALVE (GPM)35 60 100 220

MAX. FLOW RATE (GPM) 375 600 1000 2250

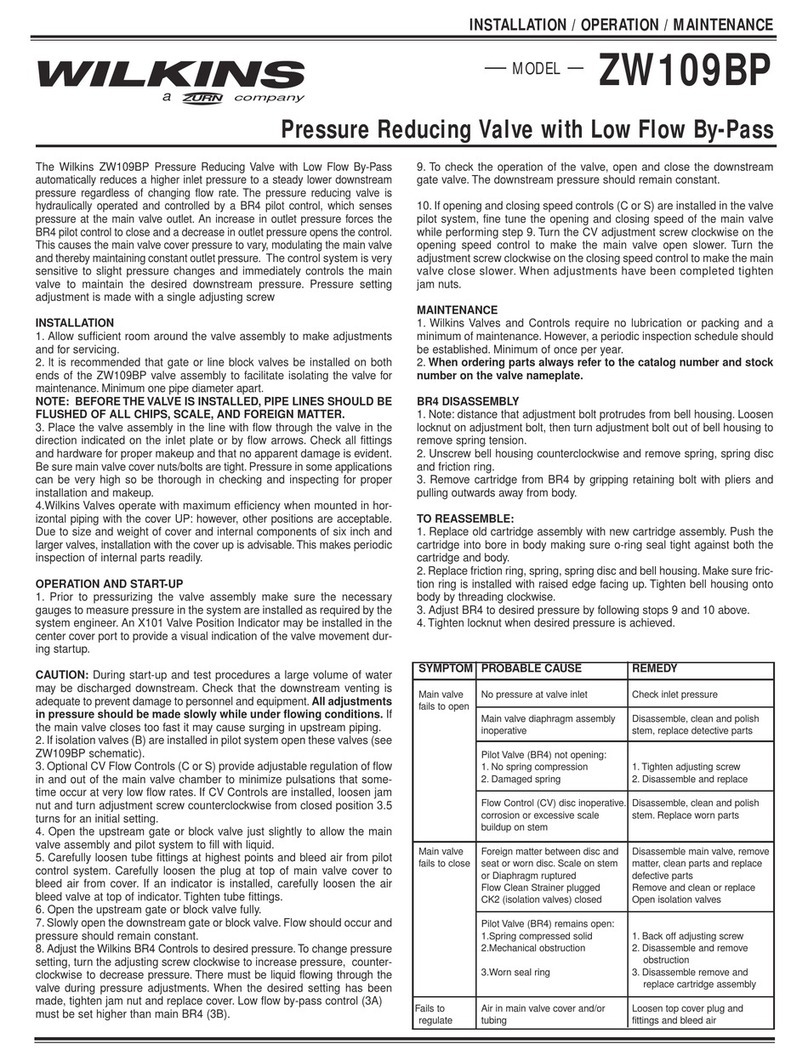

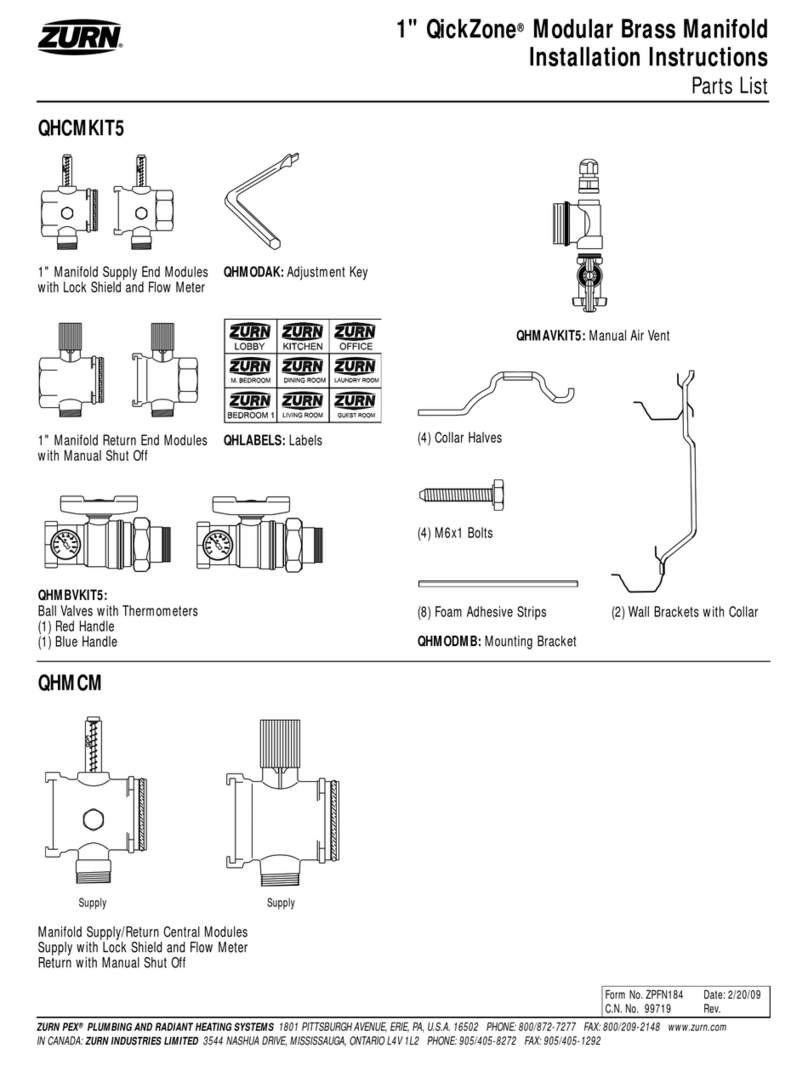

ITEM DESCRIPTION

1 3/8" PRV-PILOT BODY, LEAD FREE BRASS

2 PLUNGER, SS W/BUNA NITRILE 90 SHORE

3 MAIN CAP, LEAD FREE BRASS

4 ADJUSTMENT COVER

5 3/8"-16 ADJUSTMENT BOLT, BRASS

6 3/8" PILOT SEAT, SS

7 20-200 PSI SPRING, CHROME SILICON

8 DIAPHRAGM DISC, SS

9 SPRING DISC, SS

10 PILOT BELL, BRASS

11 O-RING, BUNA NITRILE NSF LISTED

12 5/16"-18 DIAPHRAGM NUT, SS

13 10-32X5/8 SOCKET HEAD CAP SCREW

14 DIAPHRAGM NYLON REINFORCED BUNA NITRILE

15 PRV STEM YOKE, SS

16 3/8"-16 JAM HEX NUT, SS

17 5/16" INTERNAL TOOTH LOCK WASHER, SS

18 O-RING, BUNA NITRILE NSF LISTED

19 UL TAG RED, BRASS

18

12

14

17

15

8

6

1

2

7

10

3

13

11

5

4

16

9

Maintenance Instructions

Maintenance Instructions Installation Troubleshooting