INTRODUCTION

SHIPPING DAMAGE

On receipt of your Zytronic Projected Capacitive ZXY100® Touch Controller Touchscreen

Product, if you notice damage to the shipping carton, or concealed damage, be sure to save

all packing materials for later inspection by the carrier, who is responsible for any shipping

damage.

WARRANTY

If failure occurs during the warranty period of the product, please contact the point of sale

from which the product was purchased.

CARE AND CLEANING

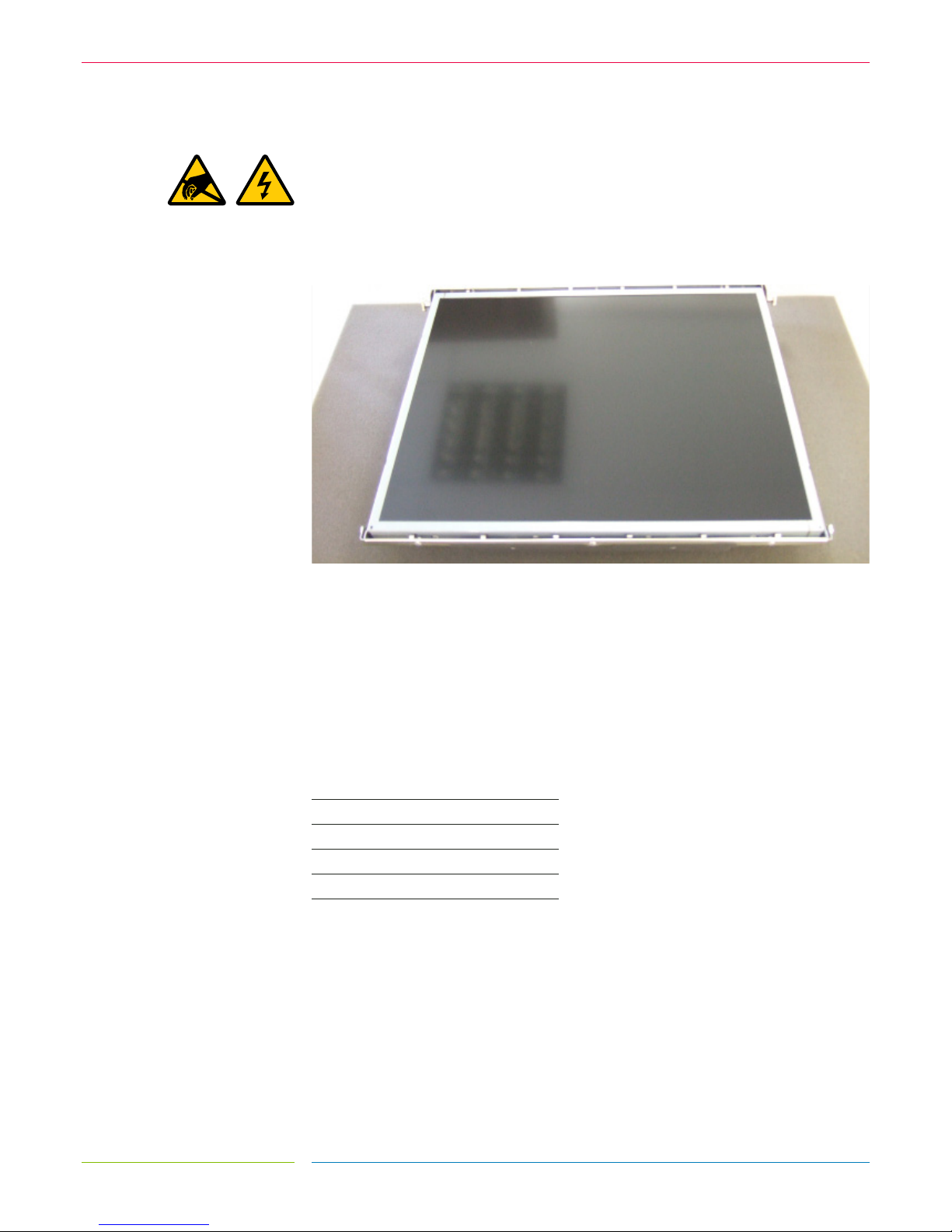

Handle the touchscreen with care prior to and during installation. Do not pull or stress

cables/flexible cables and ensure no damage is caused to the touchscreen prior to

installation. Clean the touchscreen surfaces with a glass cleaning solution and soft lint-free

cloth. Ensure that the surfaces are clean and dry before integration of the touchscreen.

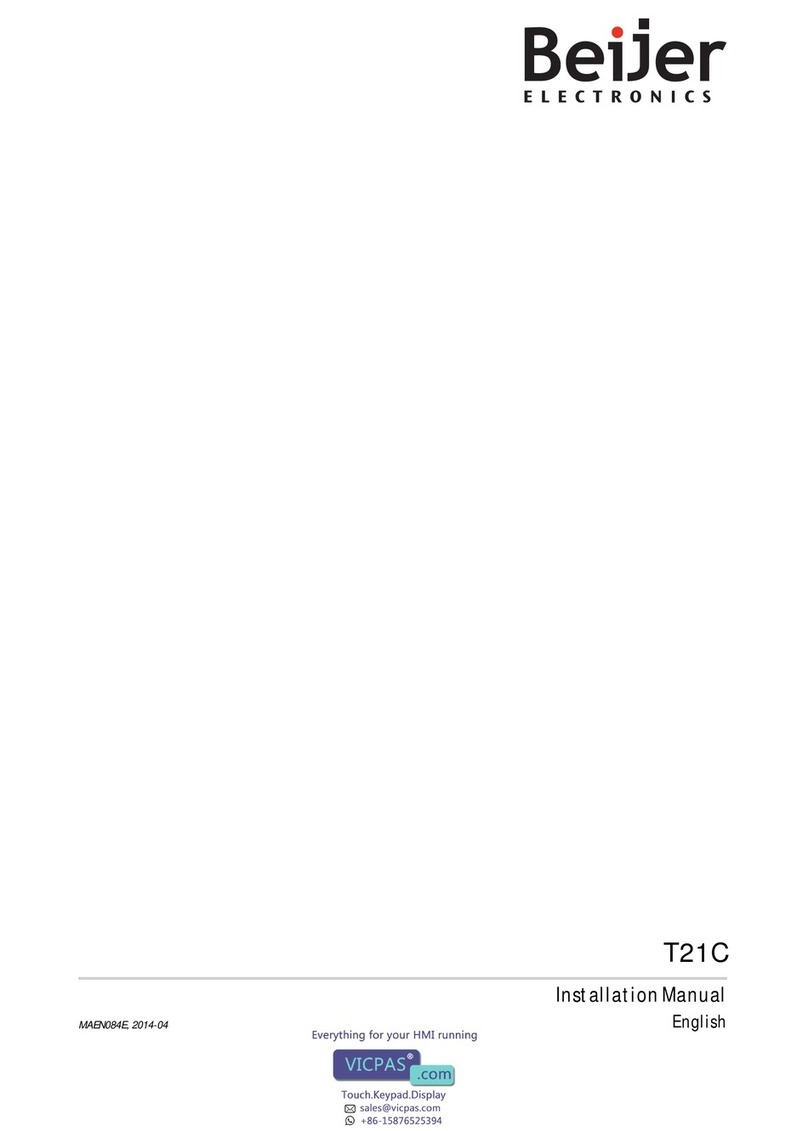

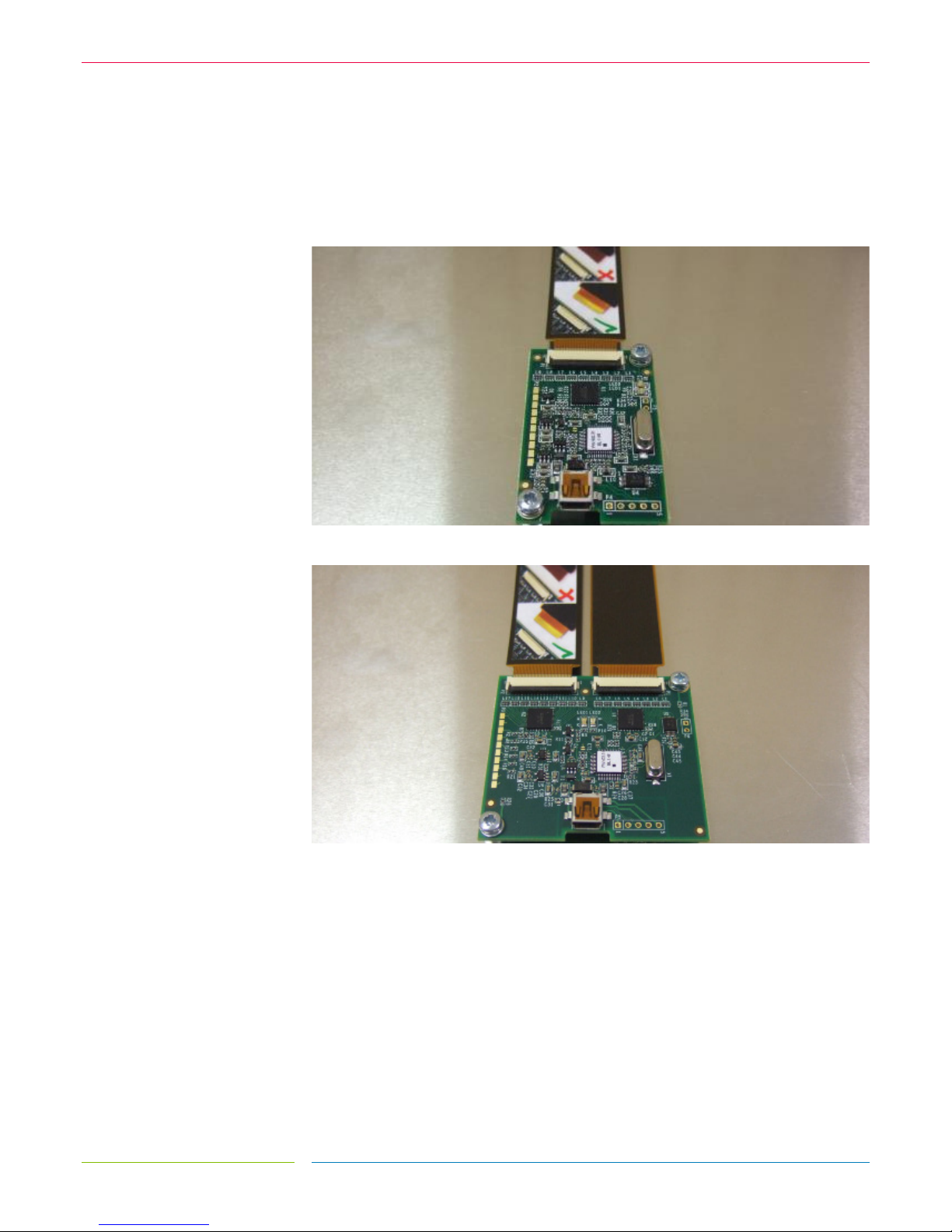

Industry standard Anti-static procedures for electronic equipment must be followed when

handling the touchscreen sensor and controller PCB during all stages of unpacking and

installation of the product to prevent damage to the product due to high levels of ESD.

UNPACKING YOUR TOUCHSCREEN

Ensure that the following items are present and in good condition:

Zytronic Projected Capacitive ZXY100® Touch Controller(s) and touchscreen sensor(s).

Users can download the latest Zytronic Projected Capacitive ZXY100® Touch Controller

Touchscreen Driver / Configuration Software and User Manual directly from the Zytronic

website. www.zytronic.co.uk/support

BEFORE YOU BEGIN

Before proceeding with the touchscreen installation ensure the following:

• Your Windows operating system is correctly installed and operating with your mouse.

• Ensure that all other touchscreen manufactures Driver Software/old touchscreen

Driver software is uninstalled from the host computer to avoid software conflicts.

• Ensure that there is a free USB or Serial port available on the host computer to connect

the desired Zytronic Projected Capacitive ZXY100® Touch Controller Touchscreen.

• Ensure that Industry standard Anti-static procedures for electronic equipment are

followed during unpacking and installation of the product.