1

Introduction

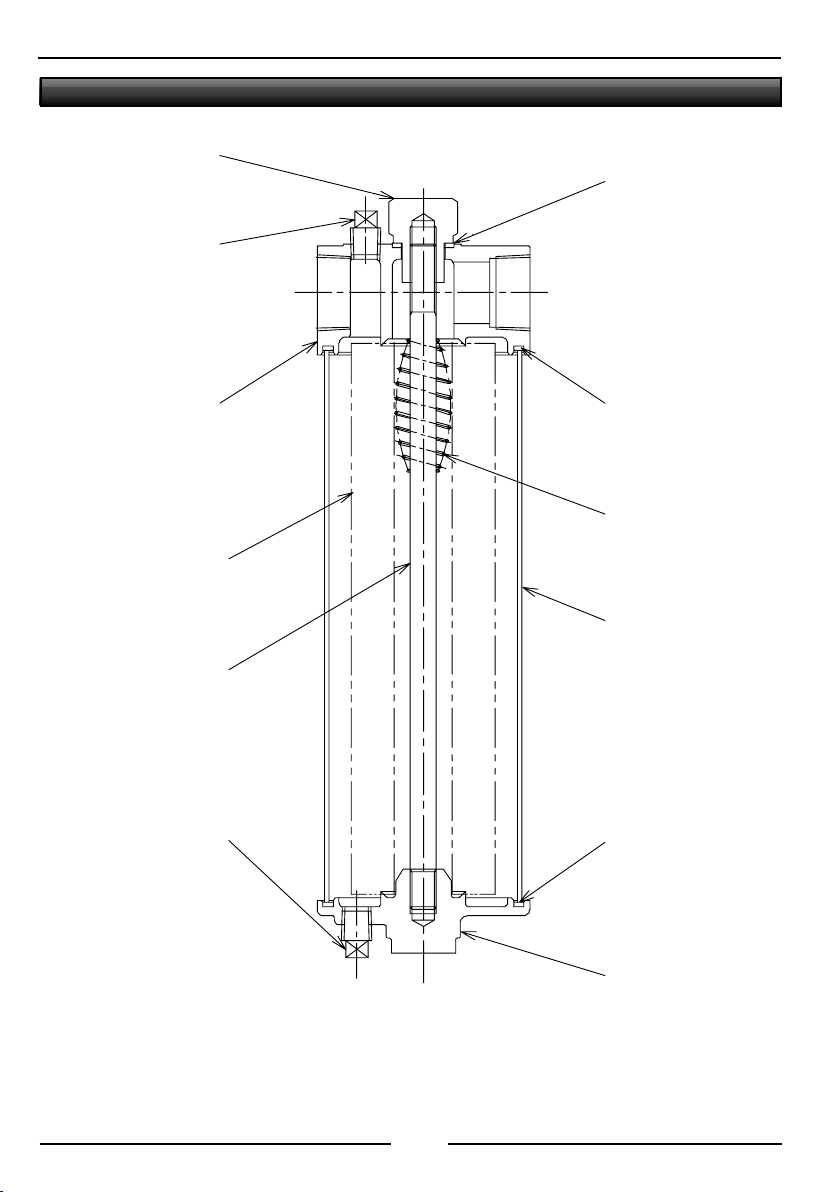

This instruction manual applies to 3MTM filter housing, 1BS-T / 1BS-TW series.

■Read this manual before you use the filter housing.

■Read this manual carefully to understand it well and use the filter housing properly.

■Store the manual with care after you read it and refer to it whenever necessary.

■If you misplace or lose the manual, inform it to us or our agent promptly.

■If you use the filter housing in the way different from the way described in this manual, we cannot guarantee security.

■Do not duplicate or reprint this manual without permission from 3M.

■In order that you use the housing filter safely, this manual contains pictorial indications below.

For your safety

■Use this filter housing below the design pressure. Otherwise, it may cause leakage or breakage.

■Never use gases with the filter housing. If it should be broken, there may cause damages to human bodies and

properties.

■If you open or close the valves in an abrupt manner, the filter housing may be damaged due to pulsations of the

line pressure. Besides if you apply a shock, excessive flow rate or back flow to the filter housing, it may cause

damages to the cartridge or housing. Never use the filter housing in such improper ways.

■Never use the housing filter for corrosive fluids. In addition check the fluid in advance to see if it is appropriate to

the filter housing of 1BS-T/1BS-TW.

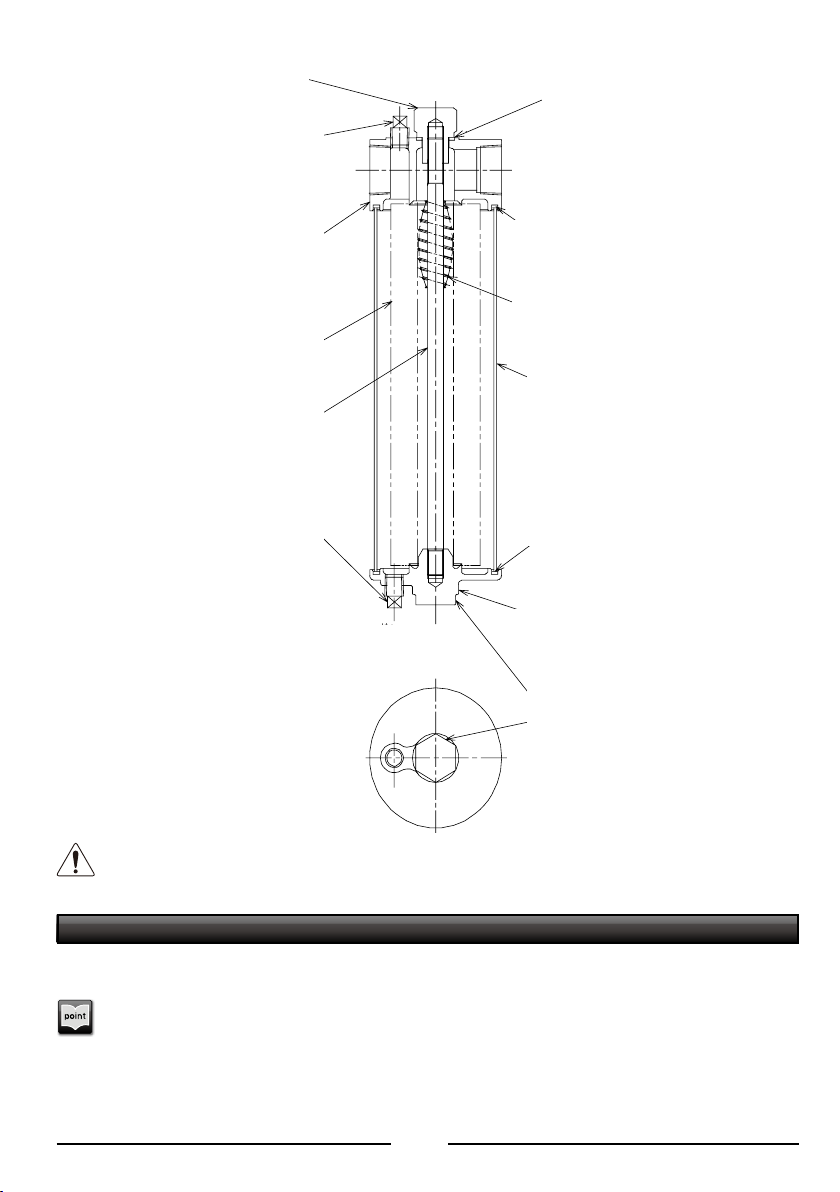

■To prevent electrostatic accumulation of electricity, Use a ground wire.

■When you use the filter housing for high-temperature fluid, its surface will become hot. Pay enough attention

when you handle the housing.

■When you replace a cartridge with another, release the pressure in the filter housing. Especially when you use

high-temperature fluid, it may blow out.

■Deterioration or destruction of gaskets and others may cause the fluid used to blow out. Inspect them regularly

and replace them if deterioration or destruction is detected.

■For the maximum allowable working pressure, working temperature, flow-rate and others, observe the conditions

specified when the filter housing was selected.

Pictorial Indications

In order to prevent harms to the people who use the filter housing and damages to the properties by guiding the

proper usage, this manual employs pictorial indications below in relation to safety labeling and operational

information including cautions.

This Symbol Represents a WARNING to Ensure Safe and Correct Operation. Failure to observe this warning

could result in personal critical injuries or death.

This Symbol Represents a CAUTION to Ensure Safe and Correct Operation. Failure to observe this caution could

result in personal injuries or damages on the assets only.

Please follow the instructions indicated by this symbol.

Useful tips for operations.

CAUTION

CAUTION

Operation

WARNING

WARNING