8.

User interface

10.

Grid standard and RS-485 address

13.

Technical data

11.

Commissioning

PVI-5000-6000-TL Quick Installation Guide

BCM.00163.1_AA

© Copyright 2014 ABB. All Rights Reserved.

Specications subject to change without notice.

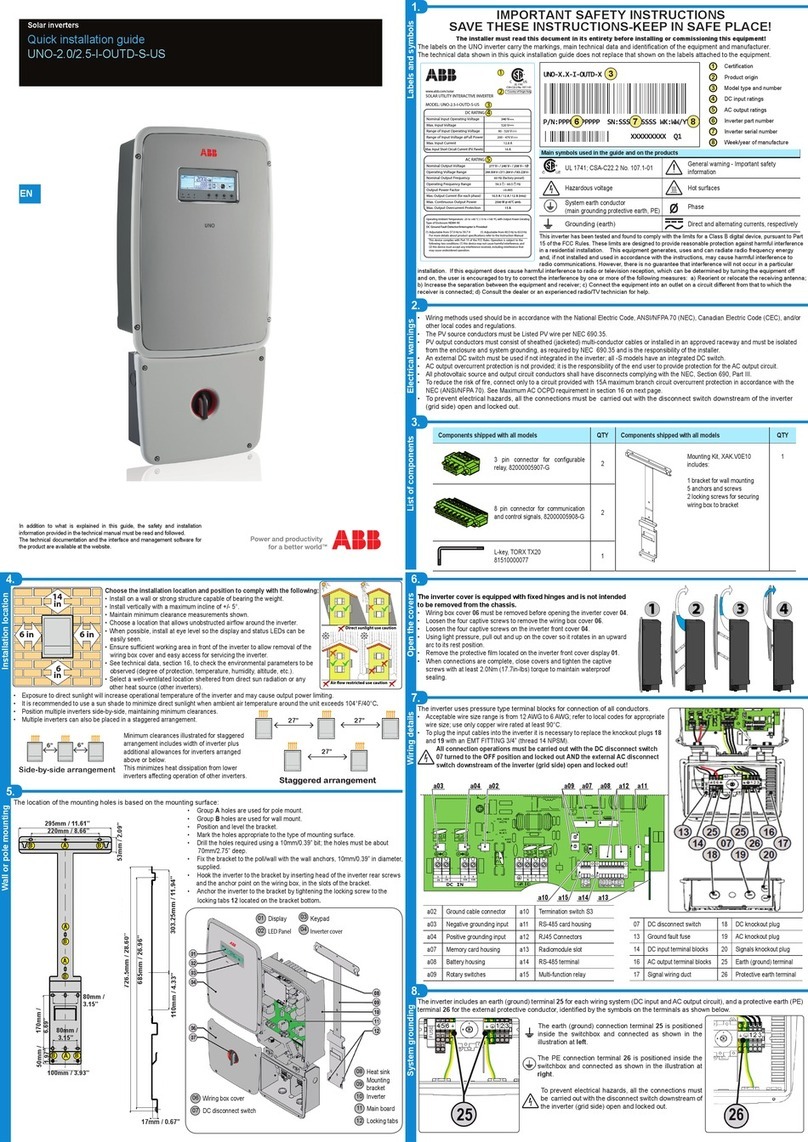

6.

AC output connections

AC output overcurrent protection is not provided with the inverter; it is the responsibility of the end user to provide overcurrent protection for the AC output circuit.

To prevent electrocution hazards, all the connection operations must be carried out with the external AC disconnect switch downstream of the inverter (grid side) open

and locked out.

Size conductors per NEC Article 310; Use 90°C copper wire only; terminal

block accommodates wire size range of 14-4 AWG.

The AC grid wiring is connected through the

inverter switchbox.

• Run an approved raceway between inverter

and external AC disconnect switch.

• Make conduit entry through openings Bor E

shown in section 4.

• Connect AC wiring to switch box terminal

block Jand the main AC ground cable to

switchbox terminal block Kshown at left.

• Table at right shows AC wiring connections

based on the AC grid type, (also found on a label

in the switchbox).

• connect wiring to the numbered terminals

based on selected grid type.

The default 240V-SPLIT-PHASE connection requires the grid Neutral to be connected for proper operation. Before connecting the inverter to the grid, the grid type must

be selected if it differs from the default 240V-SPLIT-PHASE setting. See Section 10 for instructions to change the default. If several inverters are installed to a three-phase

AC GRID, always distribute the inverters between the phases in order to reduce power imbalance between the phases.

7.

Communication wiring

Wiring for the RS-485 communication system and hardwired control options are routed through the switchbox (section 4) and into the main inverter chassis for termination.

Alarm and

monitoring connections are shown as items Qand R.

Refer to the technical manual online for connections to ALARM (Q) and Rem (remote control).

The WIND terminals (±WT ) are not isolated and can have hazardous voltages present.

These terminals must not be utilized for any purpose in a PV installation (use with

wind models only).

To connect the communication wiring, it is necessary to open the inverter cover and access the

communication connections located on the main board.

• To remove the front cover of the inverter compartment, loosen the four captive screws

indicated using the Torx screwdriver provided.

• When connection operations are complete, re-install the front covers and tighten the

cover screws with at least 1.5Nm (13.2 in-lbs) torque to ensure proper waterproof

sealing.

The RS-485 communication line connects the inverter to the monitoring devices and may be

“daisy-chained” (in-out) among multiple inverters. The RS-485 connecting cables can use both the

terminal connections R, as well as the RJ45 connectors S, to connect to the dedicated port.

If a daisy chain connection is required for AFD installed inverters (-A models) use standard

multiconductor RS-485 cable and connect the three RS-485 leads (-RTN, +T/R,-T/R)

USING ONLY THE MATING CONNECTORS.

Do not use RJ45 connectors with AFD installations.

RS-485 connectors (R)

• If terminal blocks are used, signals RTN, +T/R and –T/R have to be cabled.

• Use a cable designed for use with RS-485 communications.

• Locate mating connectors (provided in hardware bag) for the terminal block.

• Connect the three (-RTN, +T/R, -T/R) to the mating connector corresponding points.

• Attach mating connector to line up with correct signals on either upper or lower terminal

rows (two parallel terminals rows are on the terminal block and two mating connectors

are included).

RJ45 connectors (S)

• RJ45 connectors (1) and (2) available for the RS-485 communication are equivalent to

each other and can be used interchangeably for input or output of the line to create the

daisy chain connection of the inverters.

• Do not use RJ45 connectors with AFD installations.

Daisy chain connection

• Recommended length of total communication cable line for all inverters in

the system is 1,000 meters [1094 yards] or less.

• Depending on type of computer used, cable line adaptor can be RS-485-

RS232 or RS-485-USB.

Termination switch (S2)

• On the last inverter in a daisy chain, or on a single inverter, activate

termination resistance by moving switch S2 down into the ON position.

• All other inverters in daisy chain will have the switch up in the OFF

position.

Addressing each inverter

• Default setting for RS-485 address is 2 and termination switch in OFF

position.

• When multiple inverters are connected in a daisy chain, it is necessary to

assign a different RS-485 address to each unit.

See section 10 for instruction on using the display to congure settings.

Refer to the technical manual online for connections of alarm wiring (Q) and Rem (remote control).

S

RQ

T

P

P Input Mode Selector Switch S1

QExternal alarm Out Terminals

RRS-485 Terminal Block*

SRS-485 RJ45 Connector**

T

RS-485 Line Termination Resistor Switch S2

* REM-Remote control not available for -A model; terminal +R is not

accessible with AFD

** DO NOT CONNECT pin #4 when cabling units with AFD installed.

S2=OFF S2=OFF S2=ON

DAISY CHAIN CONNECTION

• LEDs indicate operating state of the inverter.

• Operating parameters of the equipment are displayed in two line LCD.

• Controls on keypad are used to review data on the LCD and access

data logged internally.

Text in LCD consists of 2 lines with 16 characters per line.

• Press the ENTER key to stop menu scrolling.

• Press the ESC key to access the three MAIN MENUS:

STATISTICS - SETTINGS - INFO

LED INDICATORS PROGRAMMING

CONTROLS

TWO LINE

LCD DISPLAY

When multiple units have been connected in a daisy chain, the individual address will need to be assigned prior to grid connection using the display menu. The grid default type,

240V Split Phase, can also be changed prior to grid connection using the display menu.

With only the array connected, set the inverter’s DC disconnect switch to ON. GREEN POWER LED will ash and YELLOW ALARM LED will be steady. The LCD will read

“Missing Grid”. Press ESC to open the menus. Use the DOWN key to scroll to Settings, and press ENTER.

The Settings menu requires an access password.

Upon selecting SETTINGS the password screen will display; the default password is 0000.

Pressing ENTER four times loads four zeroes on the display and opens the submenu.

The LCD has two visible text lines and the UP and DOWN control keys are used to scroll through the menu items. An arrow on the left side of the display highlights the current selection.

Move the arrow UP or DOWN to the desired selection and press ENTER to access the associated submenu (section 8). To return to the preceding menu, press the ESC key.

Address and Set Vgrid are described below for use in installation. Complete descriptions of the submenus can be found in the full manual on the website.

Address: In the SETTINGS menu, scroll to Address and press ENTER to open the submenu. Address values are

assigned manually using any value in the range 2 to 64. Press the UP and DOWN keys to scroll through numbers

and ENTER to select. Auto address = 1 and can be used only once; default address is set at 2.

Set Vgrid: In the SETTINGS menu, scroll DOWN to Set Vgrid and press ENTER to open the submenu. To

choose a grid connection different from the 240V Split-phase default, use the UP or DOWN key to move the

arrow to the desired selection and press ENTER. A second display screen will open; press ENTER to conrm

selection or ESC to cancel. Upon completion turn the DC Disconnect switch OFF to save changes.

The procedure for START-UP is as follows:

• Set the inverter’s DC disconnect switch to ON.

• Set the external AC disconnect switch to the inverter to ON.

Once both disconnects are closed, the inverter starts the grid connection sequence.

While the system checks for grid connection (Missing Grid) to be established, the ALARM LED turns steady YELLOW

and the POWER LED ashes GREEN.

When waiting for sunlight (Waiting Sun) the POWER LED turns steady GREEN. As soon as conditions are met, the

inverter is connected to the grid.

For –A versions ONLY, the display shows the AFD board self-test running and results upon connection. If the self-test

results are OK, the inverter will continue to Next connections.

If a potential problem on the AFD board is detected, the self-test will result in error.

Refer to section 12 below to clear the error and restart the self-test.

All versions will display the following screens during connection:

Time (seconds) remaining to complete the output voltage and

frequency values check, and whether the values are within

range.

A nal display screen conrms RISO measurement.

If all items described above test OK, the inverter is connected to the grid and displays the message, “Inverter OK”,

along with the date and time. If there is not sufcient sunlight to connect to the grid, the unit will repeat the connection procedure

until all the parameters controlling connection to the grid (voltage and frequency, conrmation of no ground fault) are within

range. During this procedure, the green LED ashes ON and OFF.

Clock malfunctioning, or other non-function related faults that do not interfere with operation, may also be shown instead of the date and time

.

12.

AFD (arc fault detection)

An autotest circuit is included in the module design of the DC ARC FAULT CIRCUIT INTERRUPTER (AFCI) solution.

The AFCI performs a self-test when the system is started, (ie

every morning when sunlight is sufcient for connection). The inverter display area shows the results of the self-test:

• If the self-test results are OK, the inverter will continue to AC grid connection.

• If a potential problem on the AFD board is detected, the self-test will result in error.

Press and hold the ESC key for three seconds to clear the error and start the restart self-test. If self-test results are OK, the inverter will re-connect

to the AC grid. If the DC arc fault is still present, the self test will result in error E053.

Refer to the technical manual online for possible solutions.

• During normal operation the input current is continually measured and analyzed.

• If a DC arc fault is detected, the inverter is disconnected from the AC grid and error E050 will be displayed.

Refer to the technical manual online for possible solutions.

The AF self-test can be manually started anytime using the following procedure:

1. Turn off the inverter (switching off both DC and AC switches) and,

2. Turn on both the DC and AC switches waiting for display communication of self-test result.

Contact us

www.abb.com/solarinverters

POWER LED GREEN: On if the inverter is working correctly. Flashes when checking the grid or if there is insufcient sunlight.

ALARM

YELLOW: The inverter has detected an anomaly. Anomaly is shown on the display

GFI RED: Ground fault on the DC side of the PV array. Error is shown on the display.

ESC Used to access the main menu, go back to the previous menu, or go back to the previous digit to be edited.

UP Used to scroll up the menu options or shift the numerical scale in ascending order.

DOWN Used to scroll down the menu options or shift the numerical scale in descending order.

ENTER Used to conrm an action, access submenu for selected option (indicated by >arrow symbol) or switch to next digit to be edited.

To adjust frequency and disconnect times to meet local utility requirements, modications are made using the Aurora Manager-TL software. The software, with

instructions to download and install on a PC, can be found on the website

Prior to connecting to the grid, with the inverter’s DC disconnect switch set to ON, a computer, with Aurora Manager-TL software installed, should

be connected to the inverter via an RS-485-USB adapter (not included). The USB driver les and instructions for installation can be found on the website.

PC-inverter connection cable required is standard USB 2.0 cable, terminals type A and B.

After frequency and disconnect time values have been adjusted, turn DC power OFF and ON to save new data. Changes to parameters must be

made to meet the requirements of the local utility. Entry of improper values could cause inverter to shut down.

Cond.

Simulated utility source Max.time (sec) at 60Hzabefore cessation of current to

the simulated utility

Voltage (V) Frequency (Hz)

A<0.50 Vnor bRated (60Hz) 0.16 (Fixed)

B0.50 Vnor b ≤ V < 0.88 Vnor (Adjustable) Rated (60Hz) 2 (Fixed)

C1.10 Vnor b< V<1.20 Vnor (*) (Adjustable) Rated (60Hz) 1 (Fixed)

D1.20Vnor ≤ V (*) Rated (60Hz) 0.16 (Fixed)

ERated f > 60.5 Hz (Default) (Adj. 60.2 to 63.0 Hz) 0.16 (Default) (Adj. 0.16 to 300 sec)

FRated f < 59.3 Hz (Default) (Adj. 59.8 to 57.0 Hz) 0.16 (Default) Adj. 0.16 to 300 sec)

GRated f< 57.0 Hz 0.16 (Fixed)

HRated f > 63.0 Hz 0.16 (Fixed)

9.

Frequency and disconnect parameters

The Statistics, Settings and Info menus can be accessed with just the array connected. Some parameters (e.g. current, voltage, power, partial energy,

lifetime energy etc.) are available only after grid connection.

Based on individual installations, the following parameters may need to be congured prior to initial grid connection:

• The RS-485 bus address for daisy chain (section 10),

• AC grid type if different from default (section 10),

• Adjustments to default frequency and disconnection time (section 9).

Complete descriptions of the data available on the display menus can be found in the full manual on the website.

>Address

Display settings

Initializing . . .

Please wait

Inverter OK

Mon 03 Jan 11:00

240V Split Ph

Vnom = 240V

TECHNICAL DATA VALUES PVI-5000-OUTD-US PVI-6000-OUTD-US

Nominal Output Power W 5000 6000

Maximum Output Power W 5000 6000

Rated Grid AC Voltage V 208 240 277 208 240 277

Number of Independent MPPT Channels 2 2

Maximum Usable Power for Each Channel W 4000 4000

Absolute Maximum Voltage (Vmax) V 600 600

Start- Up Voltage (Vstart) V 200 (adj. 120-350 ) 200 (adj. 120-350 )

Full Power MPPT Voltage Range V 200-530 200-530

Operating MPPT Voltage Range V 0.7xVstart-580 0.7xVstart-580

Maximum Current (Idcmax) for both MPPT

in Parallel A 36 36

Maximum Usable Current per Channel A 18 18

Maximum Short Circuit Current Limit per

Channel A 22 22

Number of Wire Landing Terminals Per

Channel 2 Pairs 2 Pairs

Array Wiring Termination Terminal block, Pressure Clamp, AWG16-AWG6

Grid Connection Type 1Ø/2W Split-Ø/3W 1Ø/2W 1Ø/2W Split-Ø/3W 1Ø/2W

AdjustableVoltage Range (Vmin-Vmax) V 183-228 211-264 244-304 183-228 211-264 244-304

Grid Frequency Hz 60 60

Adjustable Grid Frequency Range Hz 57-63 57-63

Maximum Current (Iacmax) ARMS 27 23 20 30 28 24

Power Factor > 0.995 > 0.995

Total Harmonic Distortion At Rated Power % < 2 < 2

Contributory Fault Current** Apk/ARMS 36.25/25.63 36.5/25.81 31.75/22.45 36.25/25.63 36.5/25.81 31.75/22.45

Grid Wiring Termination Type Terminal block, Pressure Clamp, AWG14-AWG4

Reverse Polarity Protection Yes Yes

Over-Voltage Protection Type Varistor, 2 for each channel Varistor, 2 for each channel

PV Array Ground Fault Detection Pre start-up Riso and dynamic GFDI (Requires Floating Arrays)

Anti-Islanding Protection Meets UL 1741/IEE1547 requirements Meets UL 1741/IEE1547 requirements

Over-Voltage Protection Type Varistor, 2 (L1- L2/ L1- G) Varistor, 2 (L1- L2/ L1- G)

Maximum AC OCPD Rating A 35 30 25 40 35 30

Maximum Efciency % 97.1 97.1

CEC Efciency % 96 96.5 96.5 96 96.5 96.5

Stand-by Consumption WRMS < 8 < 8

Night time consumption WRMS < 0.6 < 0.6

User-Interface 16 characters x 2 lines LCD display

Remote Monitoring (1xRS485 incl.) AURORA-UNIVERSAL (opt.)

Wired Local Monitoring (1xRS485 incl.) PVI-USB-RS485_232 (opt.), PVI-DESKTOP (opt.)

Wireless Local Monitoring PVI-DESKTOP (opt.) with PVI-RADIOMODULE (opt.)

Ambient Air Operating Temperature Range °F (°C) -13 to +140 (-25 to +60) -13 to +140 (-25 to +60)

with derating above 122 (50)

Ambient Air Storage Temperature Range °F (°C) -40 to 176 (-40 to +80) -40 to 176 (-40 to +80)

Relative Humidity % RH 0-100 condensing 0-100 condensing

Acoustic Noise Emission Level db (A)

@1m < 50 < 50

Maximum Operating Altitude without Derating ft(m) 6560 (2000) 6560 (2000)

Enclosure rating NEMA 4X NEMA 4X

Cooling Natural Convection Natural Convection

Dimensions (H x W x D) in (mm) 41.4 x 12.8 x 8.6 (1052 x 325 x 218)

Weight lb (kg) < 59.5 (27.0) < 59.5 (27.0)

Shipping Weight lb (kg) < 78 (35.4) < 78 (35.4)

Mounting System Wall bracket Wall bracket

Conduit Connections Trade Size Kos: (2ea x 1/2”) and (2ea x 1-1/4”, 3 places side, front, rear)

DC Switch Rating (Per Contact) A/V 25 / 600 25 / 600

Isolation Level Transformerless (Floating Array) Transformerless (Floating Array)

Safety and EMC Standard UL 1741, IEE1547, IEE1547.1, CSA - C22.2 N. 107.1-01 , UL1998 UL1699B, FCC Part 15 Class B

Safety Approval cCSAus cCSAus

Standard Warranty years 10 10

Extended Warranty years 15 & 20 15 & 20

Standard - With DC Switch - Floating Array PVI-5000-OUTD-US PVI-6000-OUTD-US

With DC Switch, Wiring box and Arc Fault

Detector and Interrupter PVI-5000-OUTD-US-A PVI-6000-OUTD-US-A

*All data is subject to change without notice

** Inverter can apply that much current - Breaker will open