Disturbance Recording and Fault Locating Device DRL6600U

7. Rate-of-change frequency

recording

Power system operation has a high requirement for

frequency stability. Subtle frequency changes can

cause huge damage to generators and other electrical

equipment. The DRL6600U can truthfully record

abnormal changes of high frequency, low frequency

and frequency change rate in the power system. It is

widely adopted in power plants, substations, and for

industrial use.

8. Binary signal recording

Crucial binary signal indication information such as

protection operation, reclosing operation and change of

breaker indication can be recorded. Furthermore, the

recorded information reflects the whole process of one

complete disturbance so that crucial operation

information such as false tripping, breaker failure or

reclosing failure can be analyzed.

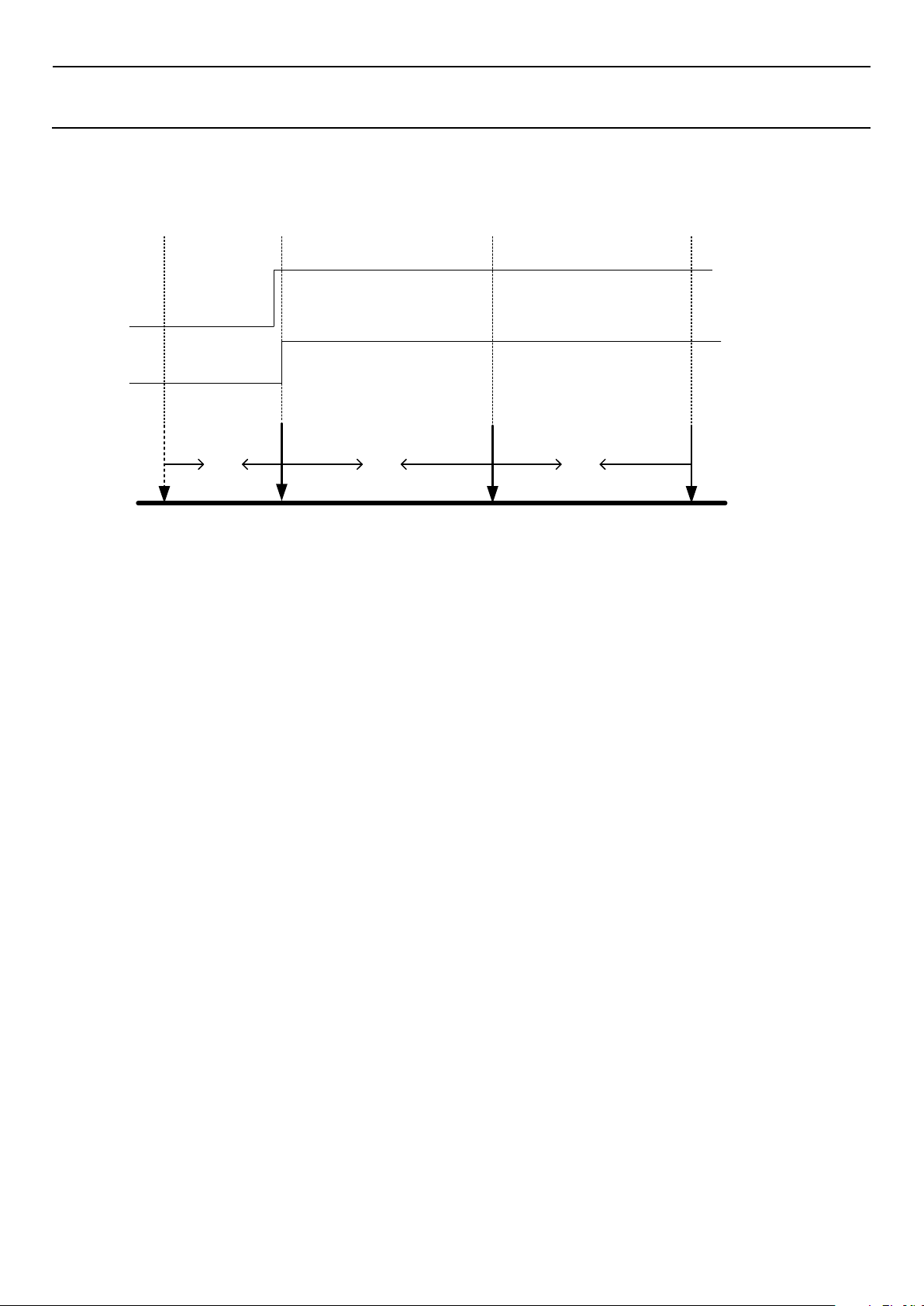

9. Fault Locating

Fault location by impedance measurement calculates

the linear impedance between the terminal and the fault

location, and in turn determines the distance to the

disturbance.

When the corresponding parameters like line length

and line impedance have been entered, once a phase-

to-ground or phase-to-phase short circuit happens a

recording will be started. Based on the impedance at

the time the short circuit happens, the DRL6600U

automatically calculates and determines the distance

between the device and the fault point.

10. Data analysis

DRL6600U provides a cross-platform waveform

analysis tool, available in both Windows and Linux

operation systems.

With a convenient and fast channel selecting mode, it's

able to show any selected signal on the same page,

and to compare and analyze currents and voltages of

different intervals, and different binary signals.

It can display several modes such as showing

instantaneous, RMS or phasor values. It adopts to

many advanced analysis functions such as sequence

components, power calculation, harmonics calculation,

location and aperiodic component.

With waveform copy and paste functions it's convenient

and fast to select and re-save the required channels of

the record, and then form new waveform files for

accident analysis and fault location.

Direct shortcut keys and tool tips bring users

convenience to operate all software functions.

Through the frequency following mode, accurate

values of analog signals deviating from 50Hz can be

acquired.