PCS100 ESS User Manual | 2UCD190000E001 rev. J 5

Table of Contents

1Overview.......................................................7

1.1 User Benefits...............................................7

1.2 Features......................................................7

1.3 Applications.................................................7

2Model Definition.............................................8

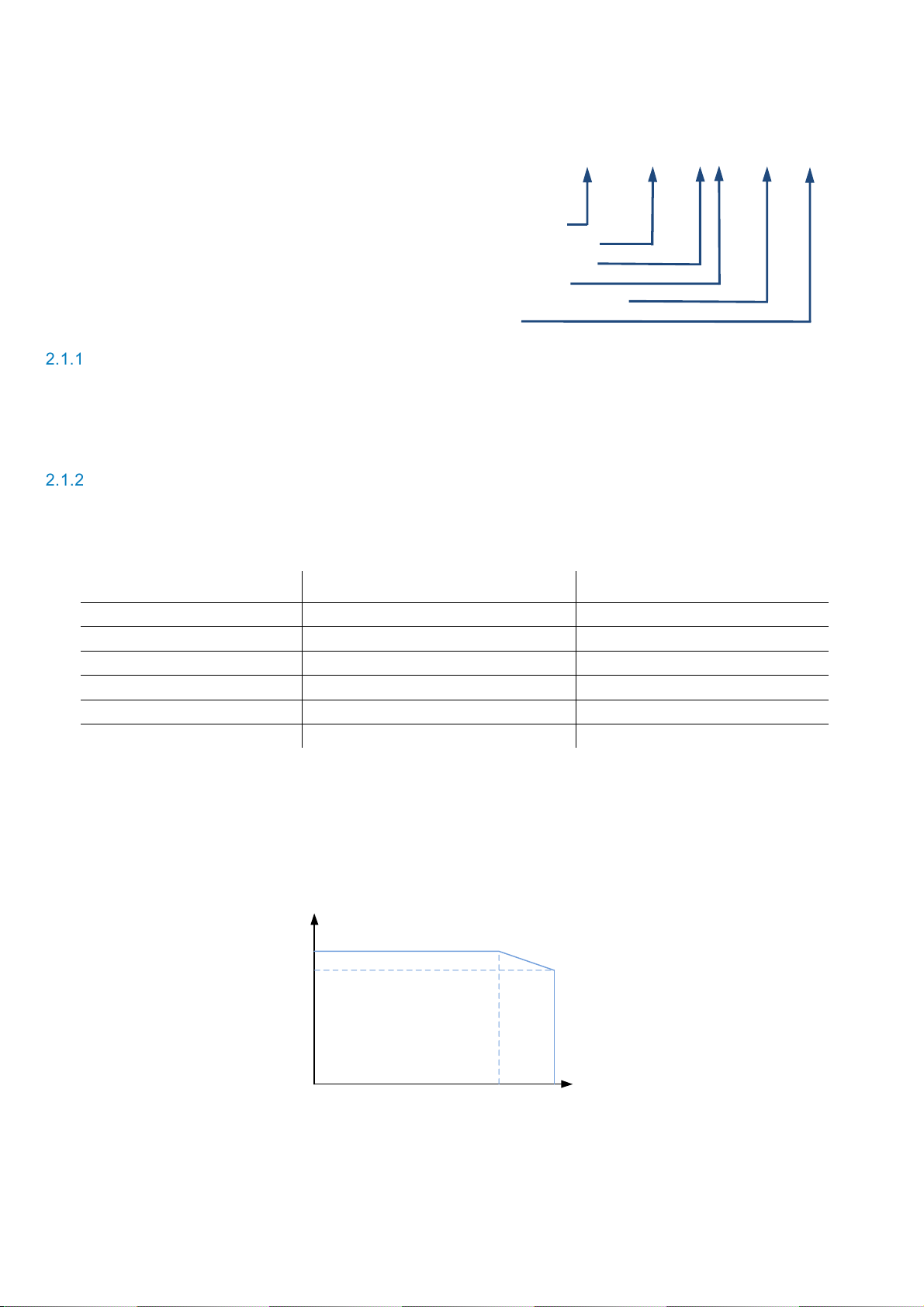

2.1 Type Code ..................................................8

2.1.1 Number of Power Modules ..................... 8

2.1.2 Type of Power Module............................ 8

2.1.3 Mechanical Construction........................ 9

2.1.4 Options.................................................10

2.2 Examples of PCS100 ESS Type Codes.......10

2.3 PCS100 ESS Model Range ........................12

2.3.1 PCS100 ESS D-Type Model Range.......12

2.3.2 PCS100 ESS C-Type Model Range.......13

3Technical Specification ................................14

3.1 Model Range.............................................14

3.2 Utility Side (AC).........................................14

3.3 Energy Storage Side (DC)..........................14

3.4 Standards and Certifications.......................15

3.5 Environmental ...........................................15

3.6 Protection Rating.......................................15

3.7 Service......................................................16

3.8 User Interface............................................16

3.9 Auxiliary Power..........................................16

4Sub-Assemblies...........................................17

4.1 PCS100 ESS Rack and Cabinet..................17

4.2 PCS100 Modules.......................................18

4.3 PCS100 Master Module..............................19

4.3.1 Connections on the Master Module........19

4.3.2 The PCS100 Extended I/O Board..........23

4.4 Metering Interface......................................26

4.4.1 Measurements......................................26

4.4.2 Metering Interface for Cabinet Systems.27

4.4.3 Metering Interface for Rack Systems .....27

4.5 Graphic Display Module (GDM)...................28

5The User Interface.......................................29

5.1 Graphic Display Module (GDM)...................29

5.1.1 Hiding / Showing the Control Button ......29

5.1.2 Navigation Panel...................................30

5.1.3 Status Bar.............................................31

5.1.4 Status Page..........................................32

5.1.5 Event Log Page ....................................34

5.1.6 Product Page........................................35

5.1.7 Menu Page ...........................................36

5.1.8 Starting and Stopping the PCS100 ESS.36

5.1.9 Logging in to the GDM ..........................37

5.2 Module Display Boards...............................38

6Functional Description and Setup.................40

6.1 How it Works............................................. 40

6.2 Virtual Generator Mode (VSI)..................... 40

6.3 Current Source Inverter Mode (CSI)............ 41

6.4 Selecting the System Mode (VSI or CSI)..... 41

6.5 Control Setup in Virtual Generator Mode..... 42

6.5.1 Fixed Power Mode and V/F mode .........43

6.5.2 Frequency and Voltage Droop...............43

6.5.3 Generator Settings ...............................43

6.6 Control Setup in CSI Mode......................... 44

6.7 Inputs and Measurements.......................... 45

6.7.1 Source Selection for Input References..45

6.7.2 DC Voltage Sensing .............................45

6.7.3 Grid Voltage Sensing – VR1 .................46

6.8 Limiting Control Functions.......................... 46

6.8.1 Frequency Envelope.............................47

6.8.2 Voltage Envelope .................................48

6.8.3 SOC Limiter..........................................49

6.8.4 Low Voltage Ride Through (LVRT)........50

6.8.5 Absolute Power Limits..........................51

6.8.6 Customized Power Limits......................51

6.9 Islanding and Anti-Islanding....................... 52

6.9.1 Grid Monitoring.....................................52

6.9.2 Islanding Control Overview...................53

6.9.3 Grid Loss Action...................................56

6.9.4 Re-Synchronization with the Grid..........59

6.10 Using the Converter Loading Feature.......... 59

6.11 Using the Energy Saving Standby Feature.. 59

6.12 Using the Voltage Clamping Feature........... 59

6.13 Using the DC Equalize Feature .................. 60

6.14 DC Voltage Imbalance and Ripple Protection

61

7Protection Requirements.............................. 62

7.1 Input Circuit Protection.............................. 62

7.2 Insulation Monitoring................................. 62

7.3 Arc Fault Hazards and Protection............... 62

7.3.1 Arc Fault and Standards.......................62

7.3.2 Arc Fault Protection Recommendation ..63

7.3.3 Personal protective equipment..............63

8Maintenance................................................64

9Faults, Warnings and other Events...............65

9.1 Resolving a Fault ...................................... 65

9.2 Resolving a Warning ................................. 71

9.3 Events during Normal Operation................. 76

10 Remote Monitoring ......................................77

10.1 List of Ports.............................................. 77

10.2 Cyber Security Information......................... 77

10.2.1 Cyber Security Disclaimer.....................77