ABB CWC Manual

Other ABB Relay manuals

ABB

ABB Sentry BSR23 User manual

ABB

ABB CP Series Manual

ABB

ABB Relion REC615 User manual

ABB

ABB E45 DU User manual

ABB

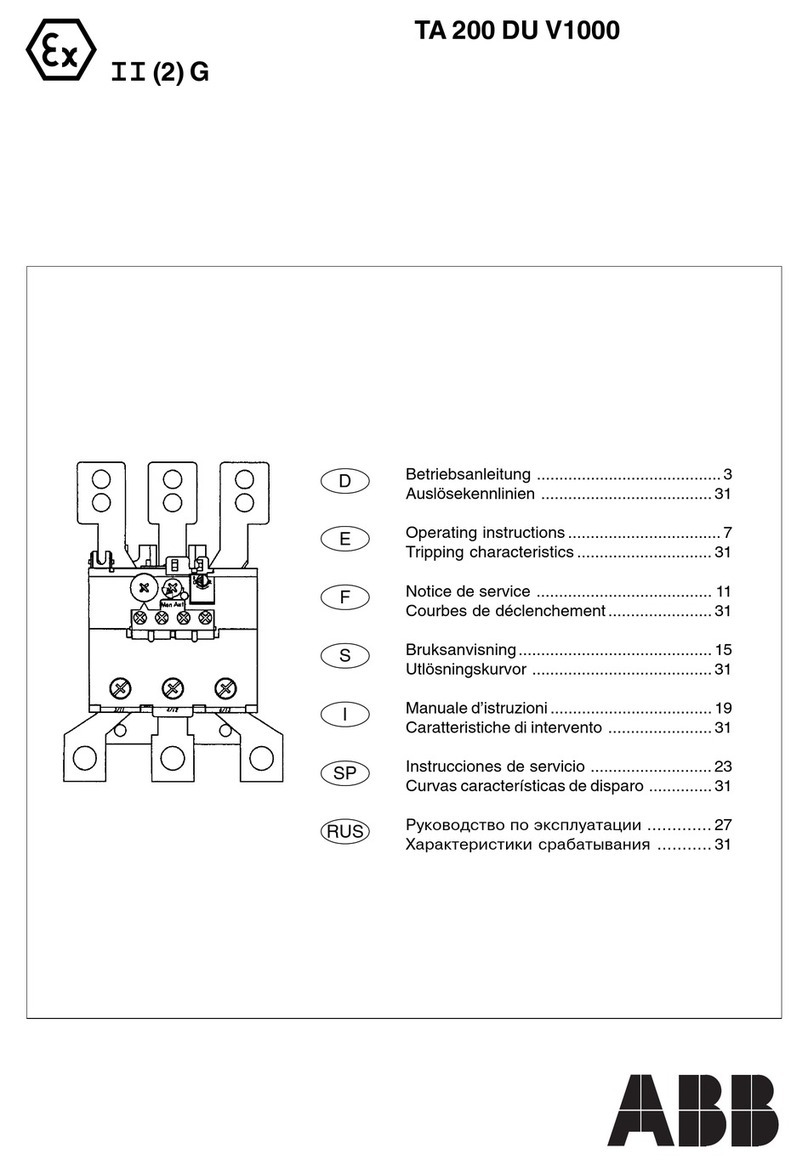

ABB TA 200 DU V1000 User manual

ABB

ABB HT595115 User manual

ABB

ABB SGR-51 User manual

ABB

ABB REJ 527 User manual

ABB

ABB RELION Series Installation and operation manual

ABB

ABB Relion 670 series Instructions for use