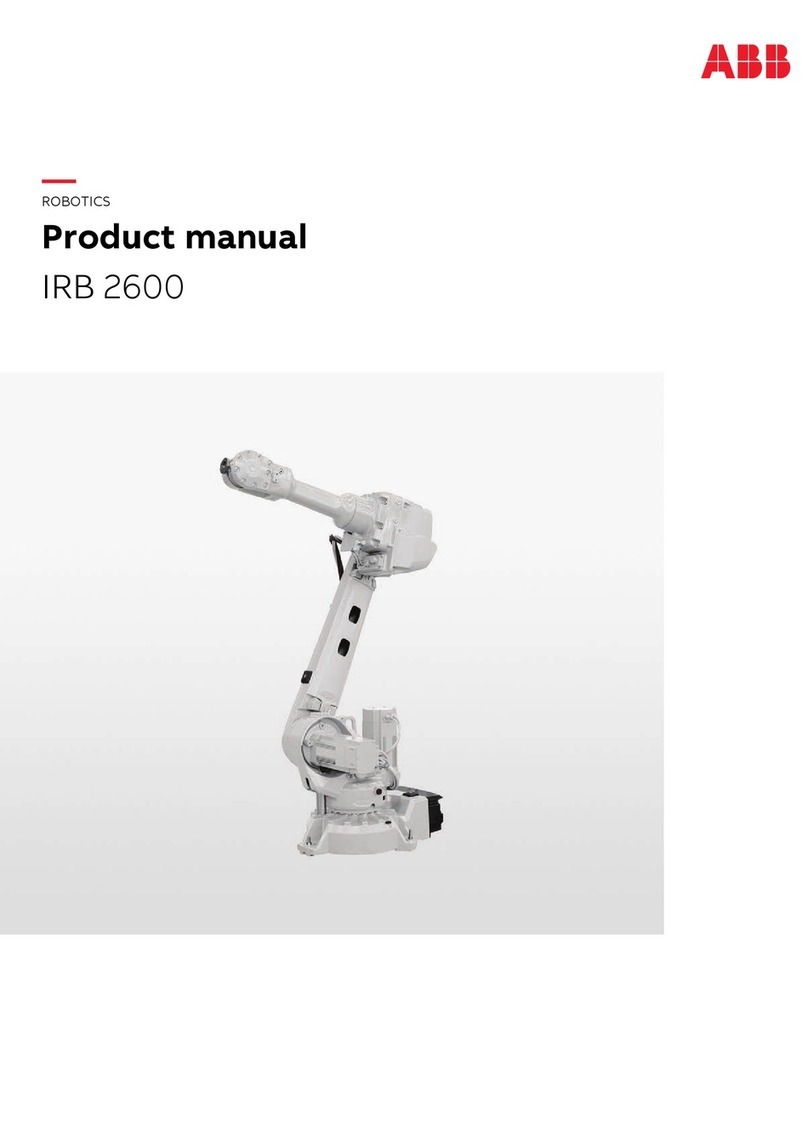

Overview of this manual

About this manual

This manual contains instructions for:

• mechanical and electrical installation of the robot

• maintenance of the robot

• mechanical and electrical repair of the robot.

The manual also contains reference information for all procedures detailed in the

manual.

Usage

This manual should be used during:

• installation, from lifting the robot to its work site and securing it to the

foundation, to making it ready for operation

• maintenance work

• repair work and calibration.

Who should read this manual?

This manual is intended for:

• installation personnel

• maintenance personnel

• repair personnel.

Prerequisites

A maintenance/repair/installation craftsman working with an ABB Robot must:

• be trained by ABB and have the required knowledge of mechanical and

electrical installation/repair/maintenance work.

Organization of chapters

The manual is organized in the following chapters:

ContentsChapter

Safety information that must be read through before performing

any installation or service work on the robot. Contains general

safety aspects as well as more specific information on how to

avoid personal injuries and damage to the product.

Safety

Required information about lifting and installation of the robot.Installation and commis-

sioning

Step-by-step procedures that describe how to perform mainten-

ance of the robot. Based on a maintenance schedule that may

be used to plan periodical maintenance.

Maintenance

Step-by-step procedures that describe how to perform repair

activities of the robot. Based on available spare parts.

Repair

Procedures that do not require specific calibration equipment.

General information about calibration.

Calibration information

Environmental information about the robot and its components.Decommissioning

Continues on next page

Product manual - IRB 2600 9

3HAC035504-001 Revision: G

© Copyright 2009-2015 ABB. All rights reserved.

Overview of this manual