Table of contents

7Overview of this manual ...................................................................................................................

91 Safety

91.1 Introduction ......................................................................................................

101.2 Safety during installation, commissioning and decommissioning ................................

111.3 Safety during setup, maintenance, service and repair ..............................................

121.4 Limitation of liability ...........................................................................................

131.5 Nation and region specific regulations ...................................................................

141.6 To be observed by the supplier of the complete system ............................................

161.7 Safety signals in the manual ................................................................................

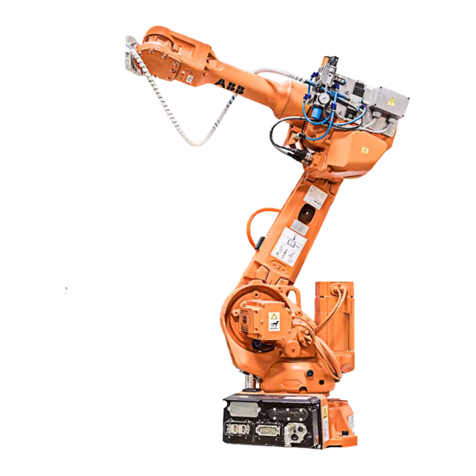

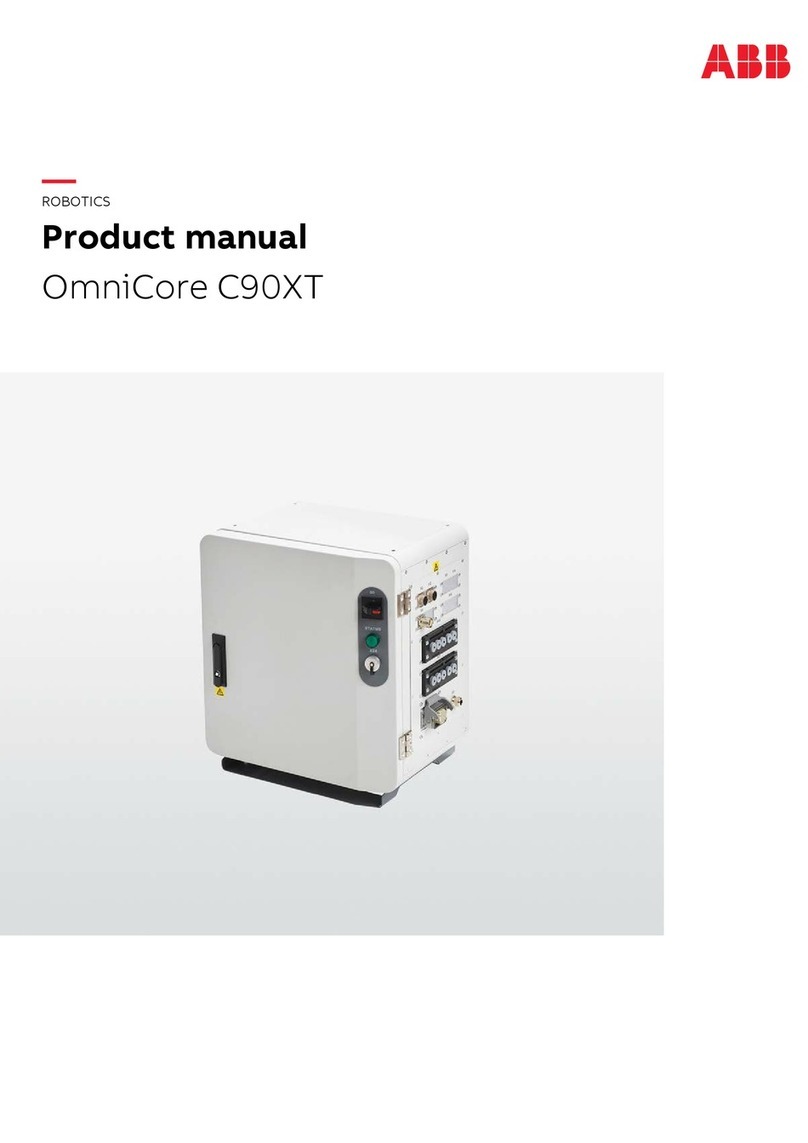

192 Description of the product

213 Installation

294 Maintenance

315 Interface

315.1 External safety interface to connected system ........................................................

385.2 Internal safety interface ......................................................................................

436 Function description

457 Operation

457.1 Starting from a non-powered status ......................................................................

467.2 Protective stop .................................................................................................

498 Decommissioning

498.1 General ...........................................................................................................

508.2 Environmental information ..................................................................................

53A Technical data

53A.1 Introduction ......................................................................................................

54A.2 Safety functions ................................................................................................

57A.3 Error messages ................................................................................................

58A.4 Starting from a non-powered status ......................................................................

59A.5 Pluto I/O ..........................................................................................................

61A.6 Safety center response times ..............................................................................

62A.7 Installation guide ...............................................................................................

Application manual - FlexLoader Standard Safety Center 5

3HAC051769-001 Revision: E

© Copyright 2014-2020 ABB. All rights reserved.

Table of contents