Installation and Operation Instructions

Part # A/SCTE-50, A/SCTE-250,

A/SCTV-50, A/SCTV-250

2305 Pleasant View Rd. Middleton Industrial Park Middleton, WI 53562

PH: (608) 831-2585 FAX (608) 831-7407

File Name: I0000142 Rev 6 Doc.

Page 1 of 3

ACI

Automation Components, Inc.

Please Read Instructions Carefully Before Installation!

Safety

This product is not intended to be used for Life or Safety applications.

This product is not intended for use in any hazardous or classified locations.

Disconnect and lock out all power sources before installation as severe injury or death may result from electrical

shock due to contact with high voltage wires.

Installation

Make sure that all installations are in compliance with all national and local electrical codes. Only qualified individuals that are

familiar with codes, standards, and proper safety procedures for high-voltage installations should attempt installation. The

current sensor will not require external power, since the power for the current sensor is induced from the conductor being

monitored.

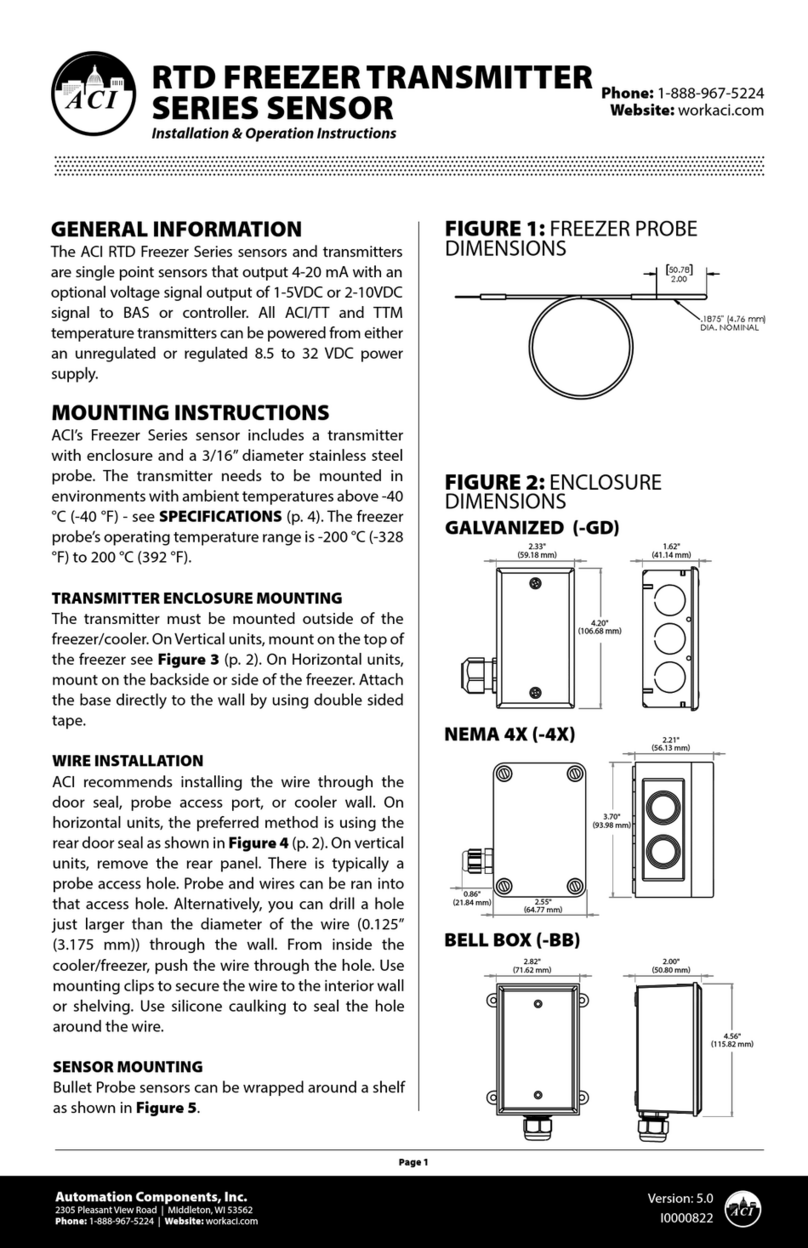

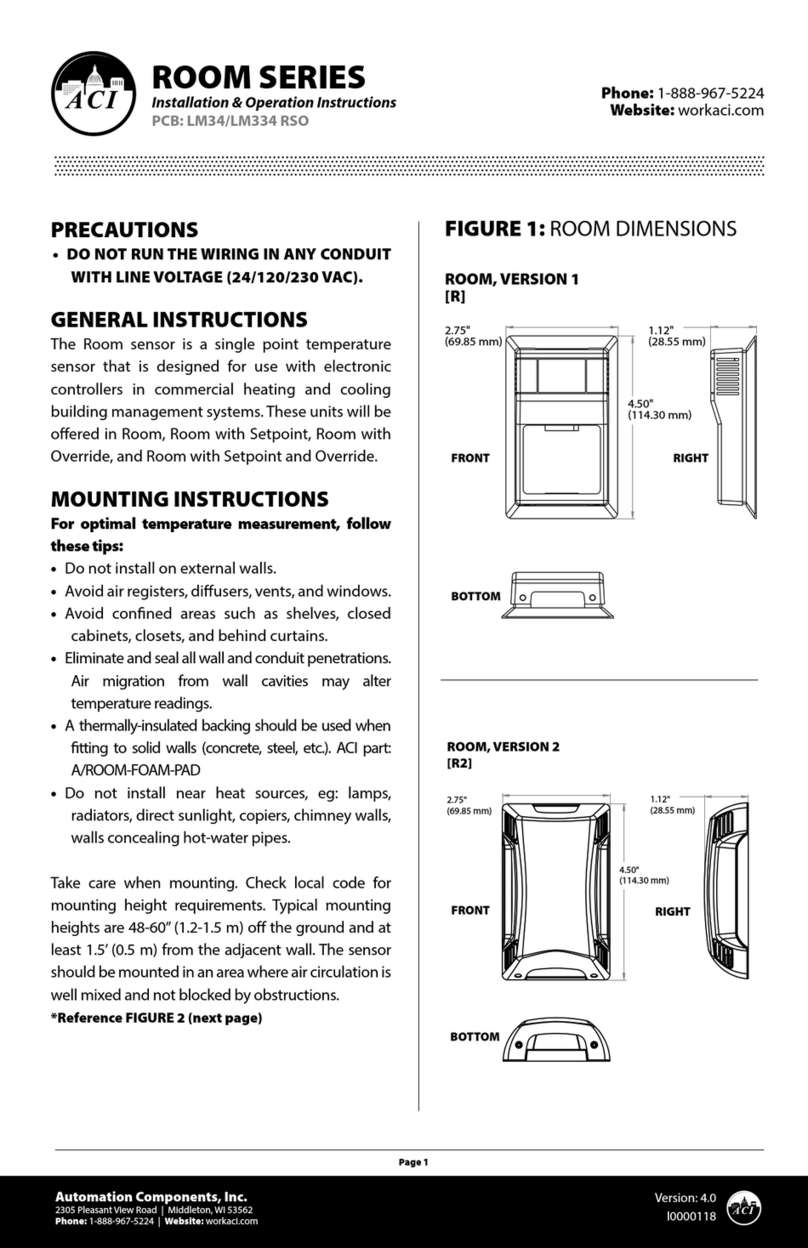

The A/SCTE & A/SCTV Series Analog Current Sensors should be used on Insulated Conductors Only! The current sensors may

be mounted in any position using the (2) #8 x 3/4” Tek screws and the mounting holes in the base or snapped directly onto the

35mm DIN rail (See Figures 1 & 2 below). Leave a minimum distance of 1” (3 cm) between the current

sensor and any other magnetic devices such as contactors and transformers.

3X3X

L

IS

T

E

D

AutomationComponents,Inc.

IN

D.C

O

N

T.E

Q

.

Middleton,WI

C

3

JH

X

ACI

A/SCTE-50

U

S

L

IS

T

E

D

AutomationComponents,Inc.

IN

D

.C

O

N

T.E

Q

.

Middleton,WI

C

3J

H

X

ACI

A/SCTE-50

U

S

Figure 1: Sensor Placed on Rail Figure 2: Sensor Removed from Rail

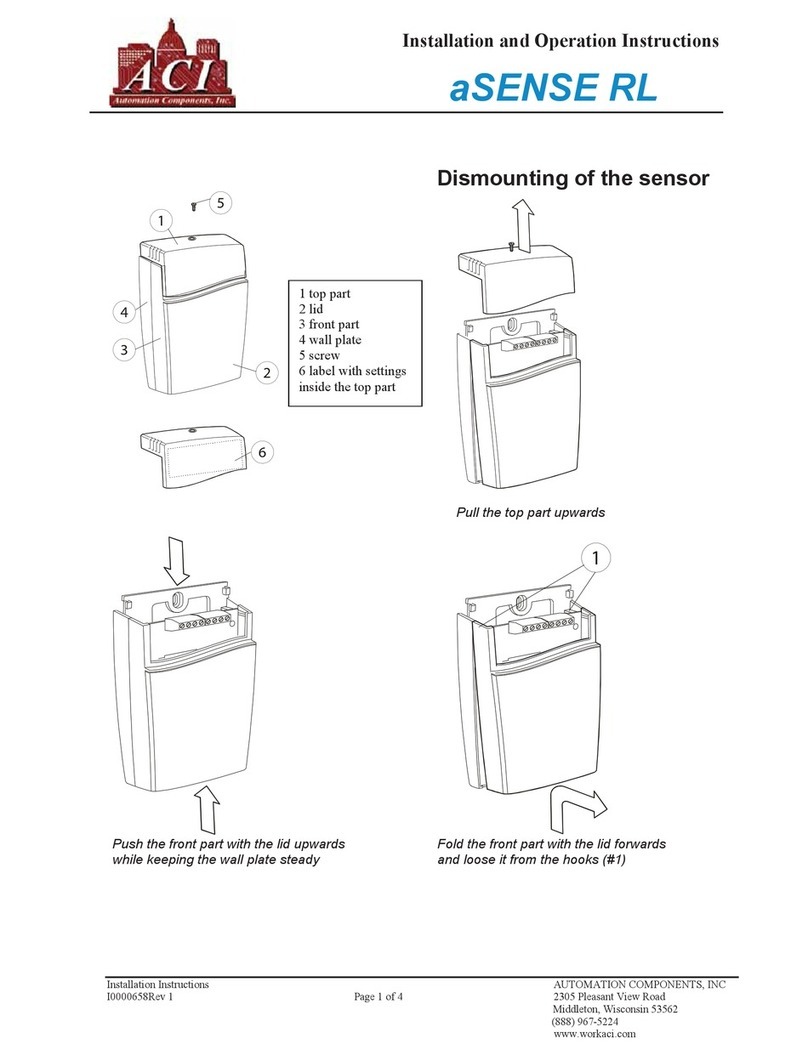

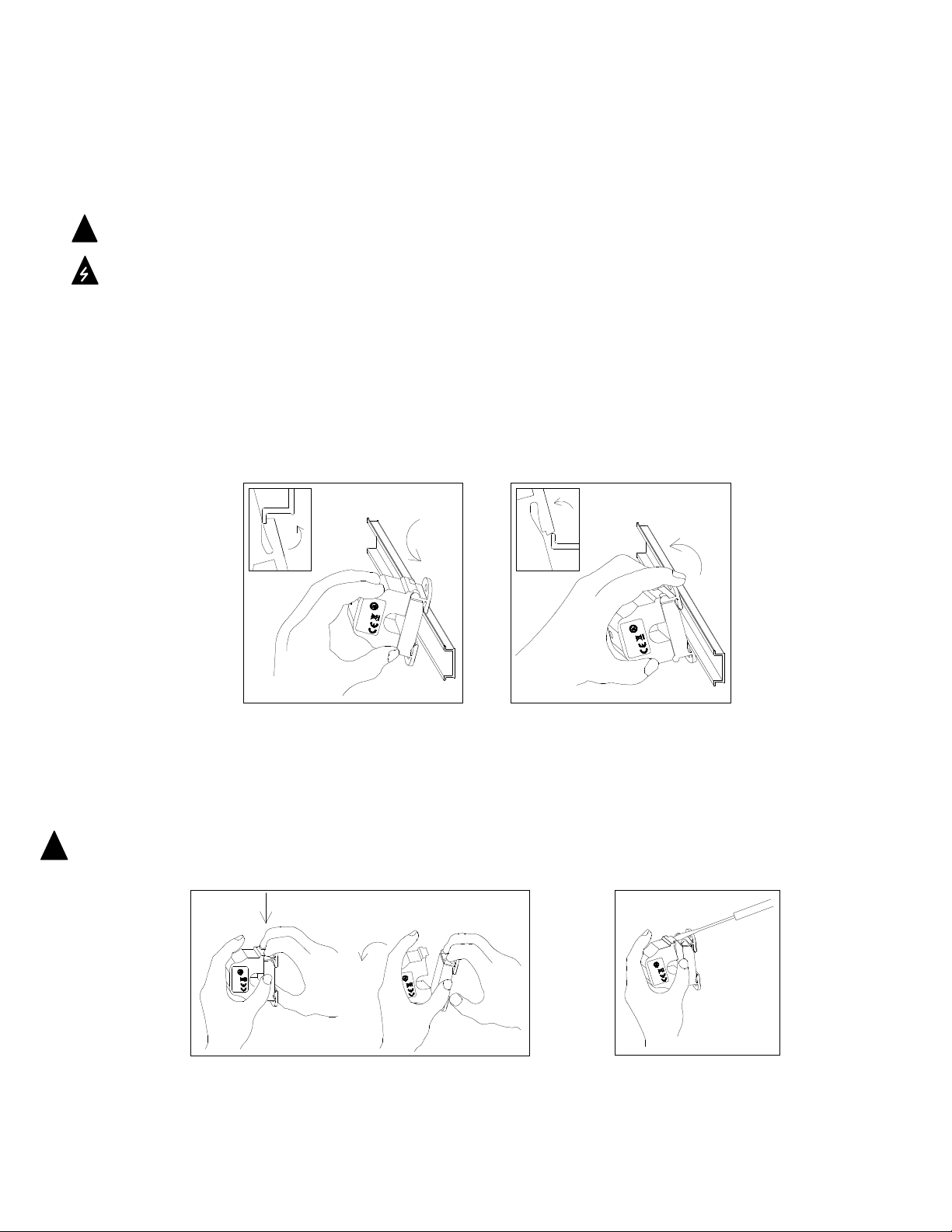

Latch Operation:

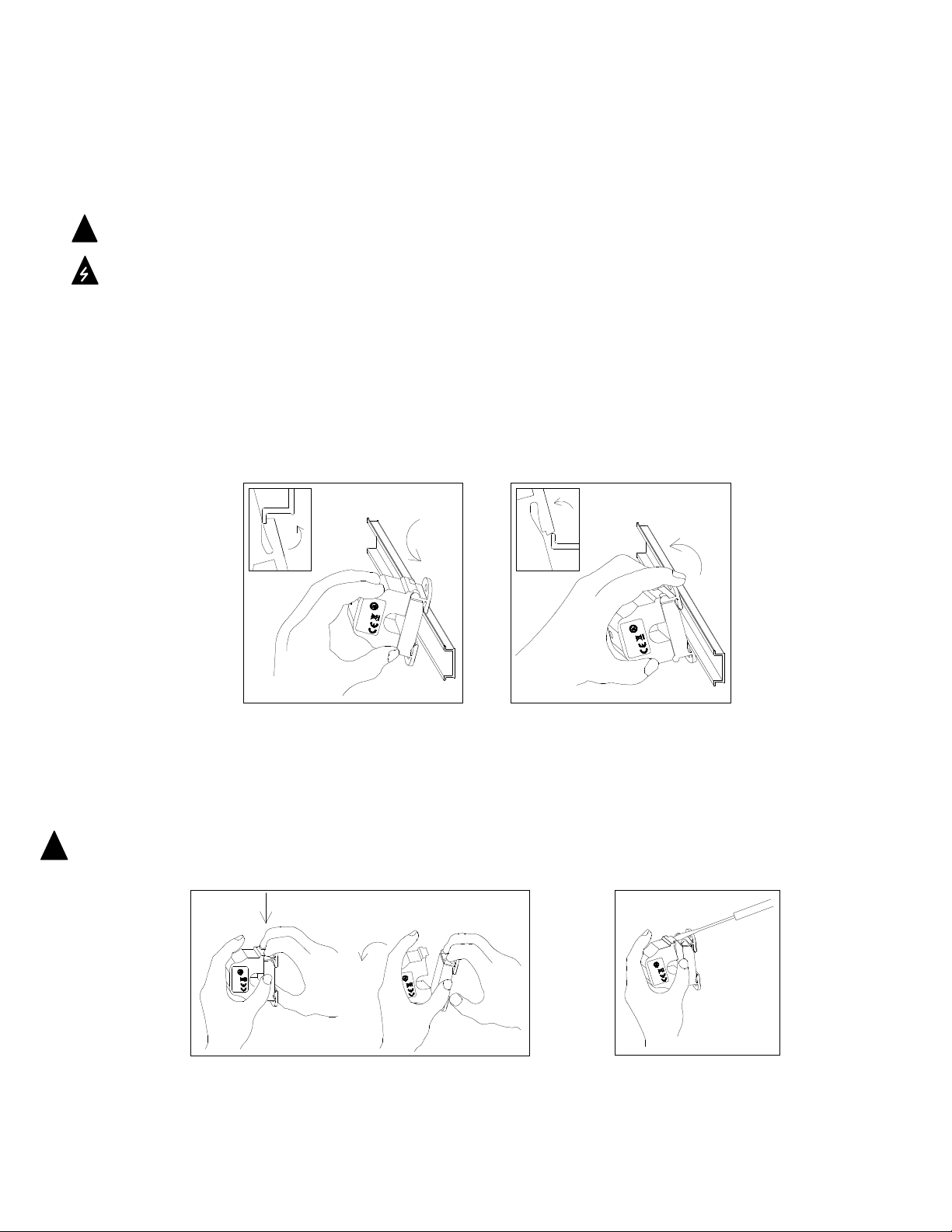

Pressing down on the two (2) side tabs and swinging the cover open opens the split core current sensor as shown in Figure 3

below. Lifting up on the latch with a flat-tip screwdriver as shown in Figure 4 below can also open the unit. Press down firmly on

the cover to close the current sensor. An audible “click” will be heard as the tab slides over the tongue on the base.

Caution: Mating surfaces of the magnetic core are exposed when the sensor is open. Silicone grease, present on the cores to

prevent rust, may capture grit and dirt if care is not exercised. Operation can be impaired if anything prevents good

contact between pole pieces. Visually check the mating parts of the core before closing the current sensor.

3JH

X

U

S

L

IS

T

E

D

IN

D

.C

O

N

T.E

Q

.

C

A/SCTE-50

ACI

USC

Middleton,W I

Automation Components, Inc.

3JHX

IND.CONT.EQ.

LISTED

CU

S

L

IS

TE

D

IND

.CO

NT

.E

Q

.

3J

HX

AutomationComponents,Inc.

ACI

Middleton,WI

A/SCTE-50

Figure 3: Opening Sensor by Hand Figure 4: Opening w/ Screwdriver

!