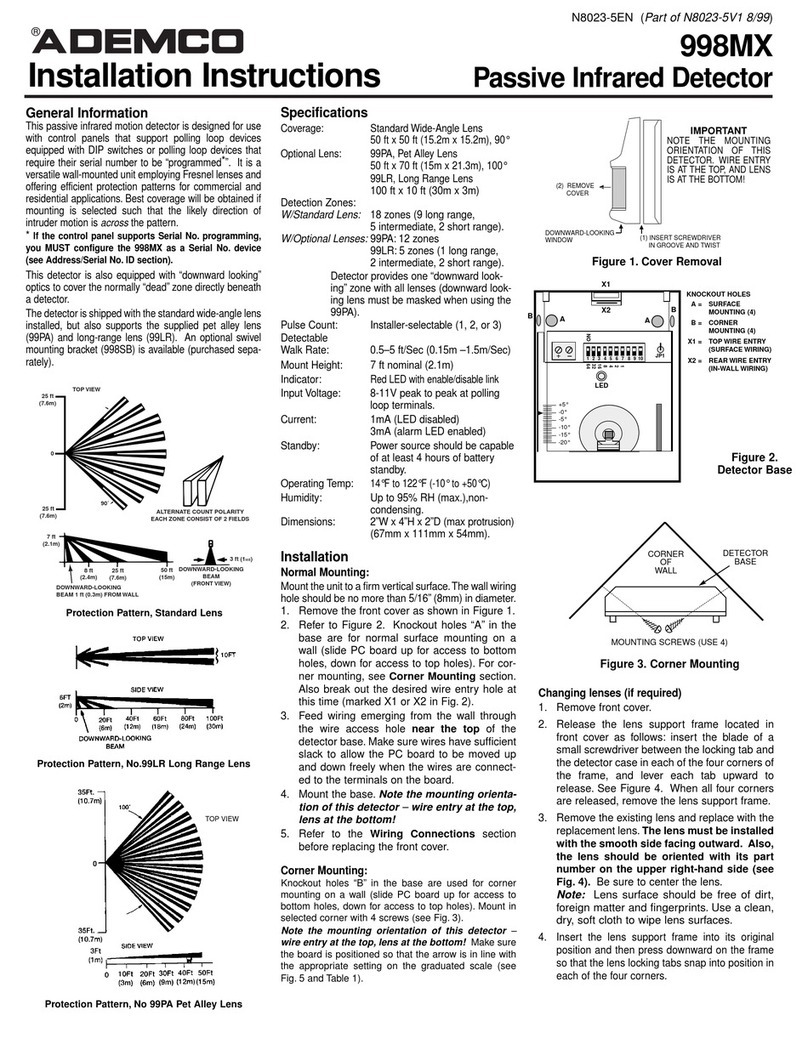

- 3 -

TROUBLESHOOTING

PROBLEM PROBABLE CAUSE REMEDY

Intermittent Rapid temperature Locate source and reposition

Alarm change. Check for detector.

electric or gas heaters,

open flames, electric

arcs, etc.

Drafts causing drapes, Eliminate source of motion.

light fixtures, display

material, etc. to move.

PIR does not Polling loop voltage Ensure that proper polarity and

appear to be supplied to PIR is in- adequate voltage is supplied,

operating. adequate, intermittent, and that wiring is intact (no

or polarity reversed. opens or shorts) and connec-

tion is secure.

Check for presence of 8-11VPP

at terminals of the PIR. If too

low, polling loop run to control

may be too long for the wire

gauge used,or polling loop cur

rent drain may be excessive.

Increase wire gauge or add No.

4197 Polling Loop Extender

module to location in the loop

where voltage boost is neces-

sary and connect it to a power

source. Alternatively, the PIR

can be tested using a 9-volt

source (such as a 9-volt battery

or a 9-volt power supply).

LED Inoperative Switch #2 not set to Set switch #2 to ÒWalk TestÓ

ÒWalk TestÓ. position.

LED malfunction. Check Return unit for service.

for broken or shorted

leads.

Detection area Repositioned furniture Caution customer about

changes. or equipment in the layout changes. Re-position

protected area. detector if necessary.

Mounting surface is Mount on secure surface.

unstable. A few degrees

of vertical shift can

change range sub-

stantially.

TO THE INSTALLER

Regular maintenance and inspection (at least annually by the installer) and fre-

quent testing by the user are vital to continuous satisfactory operation of any

alarm system. The installer should assume the responsibility of developing and

offering a regular maintenance program to the user, as well as acquainting the

user with the proper operation and limitations of the alarm system and its com-

ponent parts. Recommendations must be included for a specific program of

frequent testing (at least weekly) to insure the systemÕs operation at all times.

TESTING

IMPORTANT: Wait at least two minutes after applying power before attempting

to walk-test unit.

Before testing the detector, the protected area has to be clear; if more

convenient, the walk test can be done after close of business.

The protective systemÕs control should be disarmed during the procedure to pre-

vent reporting unwanted alarms.

Walk Test

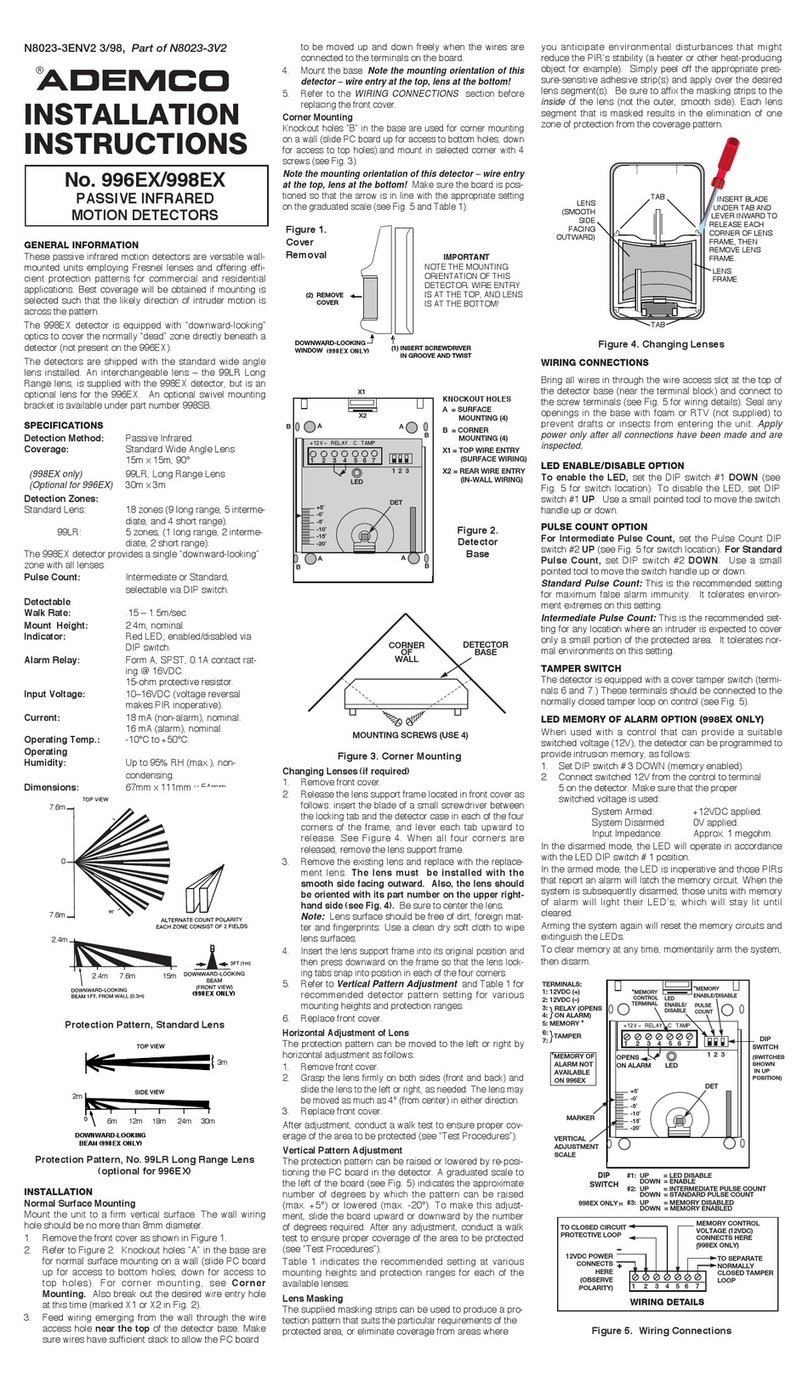

Place switch #2 to the WALK TEST position, replace the front cover, and then

walk through the protective zones. The LED will light whenever motion is detect-

ed. Be sure that the Mode Select switch #1 is in the same position in which it will

be used. For example, place it in the INSTANT position if the long range mirror

is installed. See ÒSignal ProcessingÓ above.

BE SURE TO PLACE THE WALK TEST SWITCH IN THE “DISABLE” POSITION

AFTER THE INITIAL WALK TEST IS COMPLETED.

Subsequent periodic walk tests must be done in conjunction with the indicators

of the associated control panel.

The absolute range of all Passive IR units is subject to variation because of dif-

ferent types of clothing, backgrounds and ambient temperature. For this reason,

ensure that the most likely intruder routes are well within the PIRÕs protective

zones and that walk-testing is carried out along these routes.

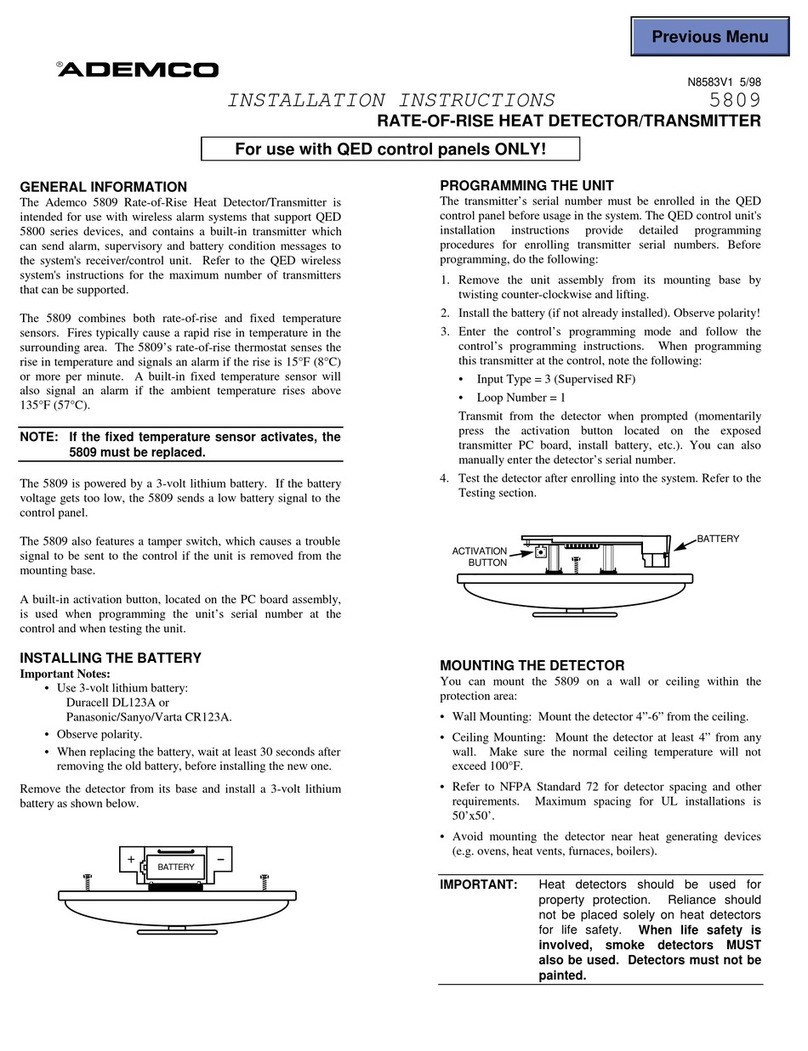

To either manually enter or "learn" the unit's serial number:

1. Enter

✱

93 Zone Programming mode.

2. Enter the Response Type and other zone information for the PIR, pressing [

✱

]

to advance from prompt to prompt.

3. At the "Input Type" prompt, enter "6" for SL (Serial Polling Device) and press [

✱

].

4. At the "Learn S/N?" prompt, enter (Y)es.

5. At the "Input S/N" prompt, either enter the serial number manually (and a "1" for

the loop number), or fault the PIR being learned (the keypad will "beep" to

confirm signal). Wait 3Ð6 seconds and fault the PIR again (the keypad should

beep again to confirm).

The PIR should now be learned. A "1" should appear under the "L" on the zone

summary screen. (If an "N" is displayed, the PIR is not learned.)

6. Press [

✱

] to continue programming zones.

If programming manually, be sure that other polling loop sensors are not activated

so that they cannot send a signal to the control while this PIR is being programmed

(mask PIRs, don't open/close doors, etc.).

¨ IMPORTANT Ã

To be sure that other polling loop devices are not activated when entering ser-

ial numbers manually, power the system down, disconnect the polling loop at

the control, power back up again, and immediately enter the program mode.

Then proceed to Step 1 (below). Remember to re-connect the polling loop

when programming is complete, powering the system down first.

MAINTAINING PROPER OPERATION

In order to maintain the detector in proper working condition, it is important that

the following be observed by the user.

1. Power should be provided at all times.

2. Units should never be re-aimed or relocated without the advice or assistance

of the alarm company.

3. The physical surroundings of the protected area should not be changed. If

furniture or stock is moved, or air-conditioning or additional heating is

installed, the system may have to be readjusted by the alarm company.

4. Conduct Walk-Test frequently (at least weekly) for proper coverage by each

detector.

SPECIFICATIONS

Detection Method: Passive infrared

Coverage: 40 ft (12.2) x 50 ft (15.2m) (wide angle mirror);

80 ft (24.4m) x 7.5 ft (2.3m) (long range/curtain mirror).

Detection Zones: 12 zones (7 main, 4 intermediate, 1 downward) (wide

angle mirror); 1 zone, 7 tiers (long range/curtain mirror)

Operating Modes: Signal Processing/Instant Response (Installer Selectable)

Detectable Walk

Rate: 0.5 Ð5 ft/sec. (0.15Ð1.5 m/sec)

Mounting Height: 7 ft nominal (2.1m), wall mounting

Indicator: Red LED

Input Voltage: 8Ð11V peak-to-peak at polling loop terminals.

Current Drain: Less than 1 mA (LED inactive), 9 mA approx. (LED

active)

Operating

Temperature: 0¡to 50¡C (+32¡ to +122¡F)

Operating

Humidity: Up to 95% RH (max.), non-condensing

Dimensions: 3

1

/

4

ÓW x 4

5

/

8

Ó H x 2Ó D (85mm x 120mm x 50mm)