55

INTRODUCTION

This product has many features for making its use more pleasant

and enjoyable. Safety, performance, and dependability have

been given top priority in the design of this product, making it

easy to maintain and operate.

DANGER

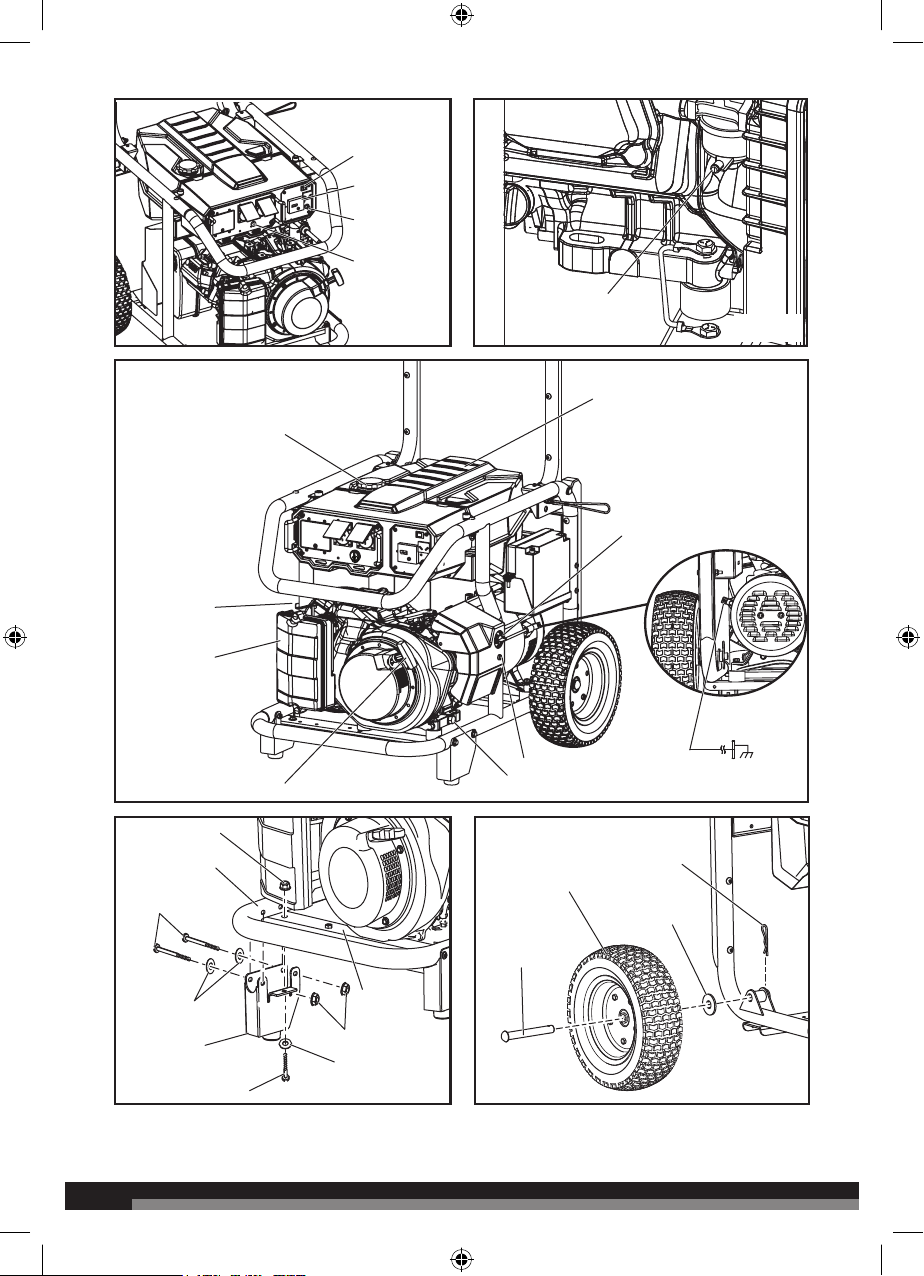

Grounding the Generator

See Figure 3.

In Australia and New Zealand, grounding of portable

generators is not recommended or required. Consult with

local electricians to determine grounding requirements

before operating with a ground connection.

GENERAL SAFETY RULES

WARNING:

Read and understand all instructions. Failure to follow

all instructions listed below may result in electrocution,

fire, and/or carbon monoxide poisoning, which will cause

death or serious injury.

WARNING:

When this generator is used to supply a building

wiring system: the generator must be installed by a

qualified electrician and connected to a transfer switch as

a separately derived system in accordance with Australian

Wiring Rules. The generator shall be connected through

a transfer switch that switches all conductors other than

the equipment grounding conductor. The frame of the

generator shall be connected to an approved grounding

electrode. Failure to isolate the generator from power

utility can result in death or injury to electric utility workers.

Save these instructions

This manual contains important instructions that should be

followed during installation and maintenance of the generator

and batteries.

ŶDo not allow children or untrained individuals to use this

unit.

ŶNever start or run the engine inside a closed or partially

enclosed area. Breathing exhaust fumes will kill you.

ŶWear eye protection as well as hearing protection when

operating this equipment.

ŶKeep all bystanders, children, and pets at least 3 m away.

ŶWear sturdy and dry shoes or boots. Do not operate while

barefoot.

ŶDo not operate the generator when you are tired or under

the influence of drugs, alcohol, or medication.

ŶKeep all parts of your body away from any moving parts

and all hot surfaces of the unit.

ŶProduct users in some areas are required to comply with

fire prevention regulations. Check with the local authorities

in your area before use.

ŶDo not touch bare wire or receptacles.

ŶDo not use the generator with electrical cords which are

worn, frayed, bare, or otherwise damaged.

ŶBefore storing, allow the engine to cool.

ŶDo not operate the generator in rain, snow, or wet weather

ŶEmpty fuel tank, close fuel valve, and restrain the unit from

moving before transporting in a vehicle.

ŶAllow engine to cool for five minutes before refueling.

ŶTo reduce the risk of fire and burn injury, handle fuel with

care. It is highly flammable.

ŶDo not smoke while handling fuel.

ŶStore fuel in a container approved for unleaded fuel.

ŶPosition the unit on level ground, stop engine, and allow to

cool before refueling.

ŶLoosen fuel cap slowly to release pressure and to keep fuel

from escaping around the cap.

ŶTighten the fuel cap securely after refueling.

ŶWipe spilled fuel from the unit.

ŶNever attempt to burn off spilled fuel under any

circumstances.

ŶUse only authorised replacement parts and accessories

and follow instructions in the Maintenance section of this

manual. Use of unauthorised parts or failure to follow

Maintenance instructions may create a risk of shock or

injury.

ŶMaintain the unit per maintenance instructions in this

Operator’s Manual.

ŶInspect the unit before each use for loose fasteners, fuel

leaks, etc. Replace damaged parts.

ŶGenerators vibrate in normal use. During and after the use

of the generator, inspect the generator as well as extension

cords and power supply cords connected to it for damage

resulting from vibration. Have damaged items repaired or

replaced as necessary. Do not use plugs or cords that show

signs of damage such as broken or cracked insulation or

damaged blades.

SPECIFIC SAFETY RULES

ŶExhaust contains poisonous carbon monoxide, a

colourless, odourless gas. Breathing exhaust can cause

loss of consciousness and can lead to death. If the

generator is running in a confined or partially-enclosed

area, the air may contain a dangerous amount of carbon

monoxide. To keep exhaust fumes from building up, always

provide adequate ventilation.

ŶAlways use a battery-powered carbon monoxide detector

when running the generator. If you begin to feel sick, dizzy,

or weak while using the generator, shut it off and get to

fresh air immediately. See a doctor. You may have carbon

monoxide poisoning.

ŶPlace the generator on a flat, stable surface with a slope of

no more than 4°.

ŶOperate in a well-ventilated, well-lit area isolated from

working areas to avoid noise interference.

ŶOperating the generator in wet conditions could result in

electrocution. Keep the unit dry.

ŶKeep the generator a minimum of 1 m away from all types

of combustible material.

ŶDo not operate the generator near hazardous material.

ŶDo not operate the generator at a gas or natural gas filling

station.

ŶDo not touch the muffler or cylinder during or immediately

after use; they are HOT and will cause burn injury.