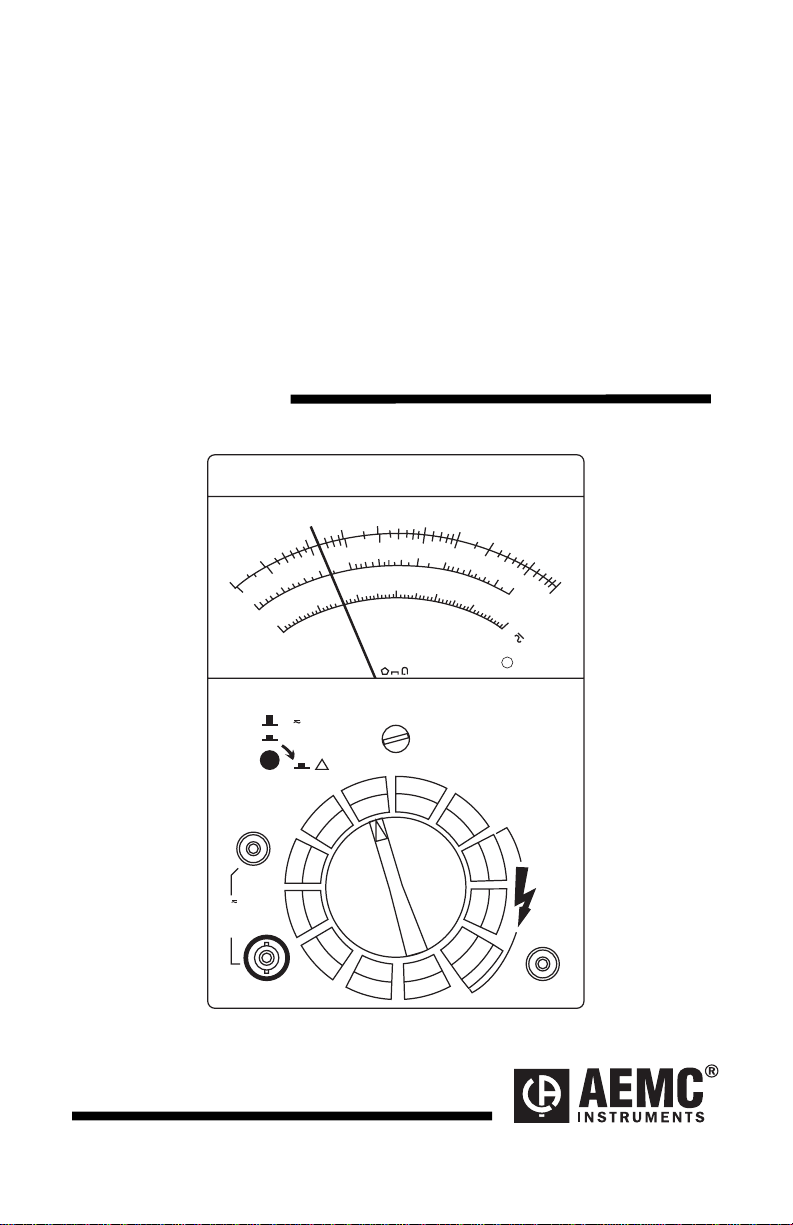

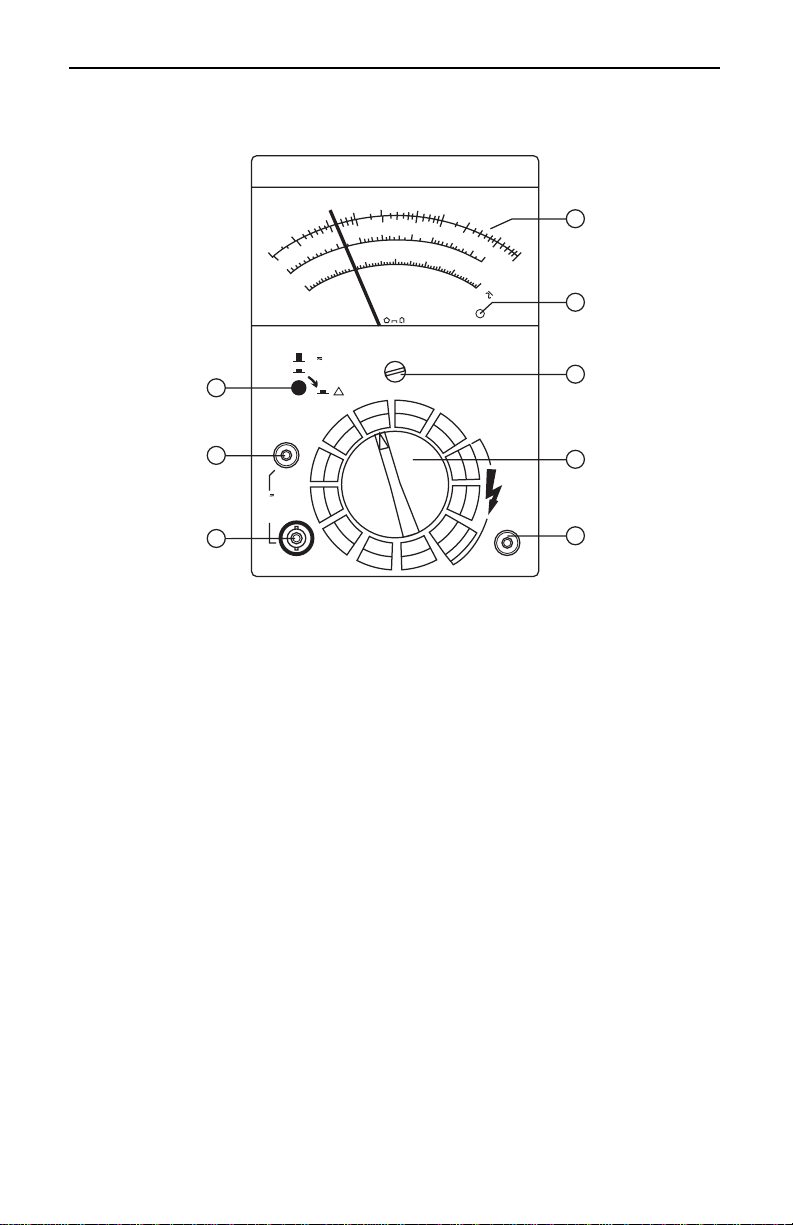

Megohmmeter Model 1000N/1100N

- 5 -

0(*2+00(7(502'(/1

5HFHL LQJ<RXU6KLSPHQW

Upon receiving your shipment, make sure that the contents are

consistent with the packing list. Notify your distributor of any missing

items. If the equipment appears to be damaged, file a claim immediately

with the carrier and notify your distributor at once, giving a detailed

description of any damage.

3DFNDJLQJ

The Megohmmeter Model 1000N (Cat. #185.100) is shipped with eight

1.5V “AA” batteries, two color-coded safety leads with insulated alligator

clips, a separate shielded lead, a separate insulated alligator clip, test

probe, one spare fuse, carrying case and instruction manual.

$FFHVVRULHVDQG5HSODFHPHQW3DUWV

AC power supply module with line cord and plug for

switch-selectable 110/220VAC at 47 to 400Hz.....................Cat. #100.142

Protective rubber case with handle......................................Cat. #2980.02

Rugged plastic carrying case, 19 x 14 x 7" ..........................Cat. #2118.07

Fuse, set of five, 0.1A slow-blow for AC supply module......Cat. #100.438

Fuse, set of one, 0.3A, for Model 1000................................Cat. #100.429

One test probe and one insulated alligator clip....................Cat. #100.404

Replacement leads for Models 1000N/1100N/5000N..........Cat. #1017.23

7-pin shielded lead, 10 ft, for Models 1000N/5000N/5100...Cat. #2950.10

Replacement Leads for Model 1000

Coaxial shielded lead ...........................................................Cat. #100.439

Set of leads: one coaxial shielded lead, pair of

safety leads, alligator clip, and test probe............................Cat. #100.482