AeroPlus Sbach 342 20CC User manual

www.aeroplusrc.com[email protected]

AeroPlusRCCopyright2013©AllRightsReserved

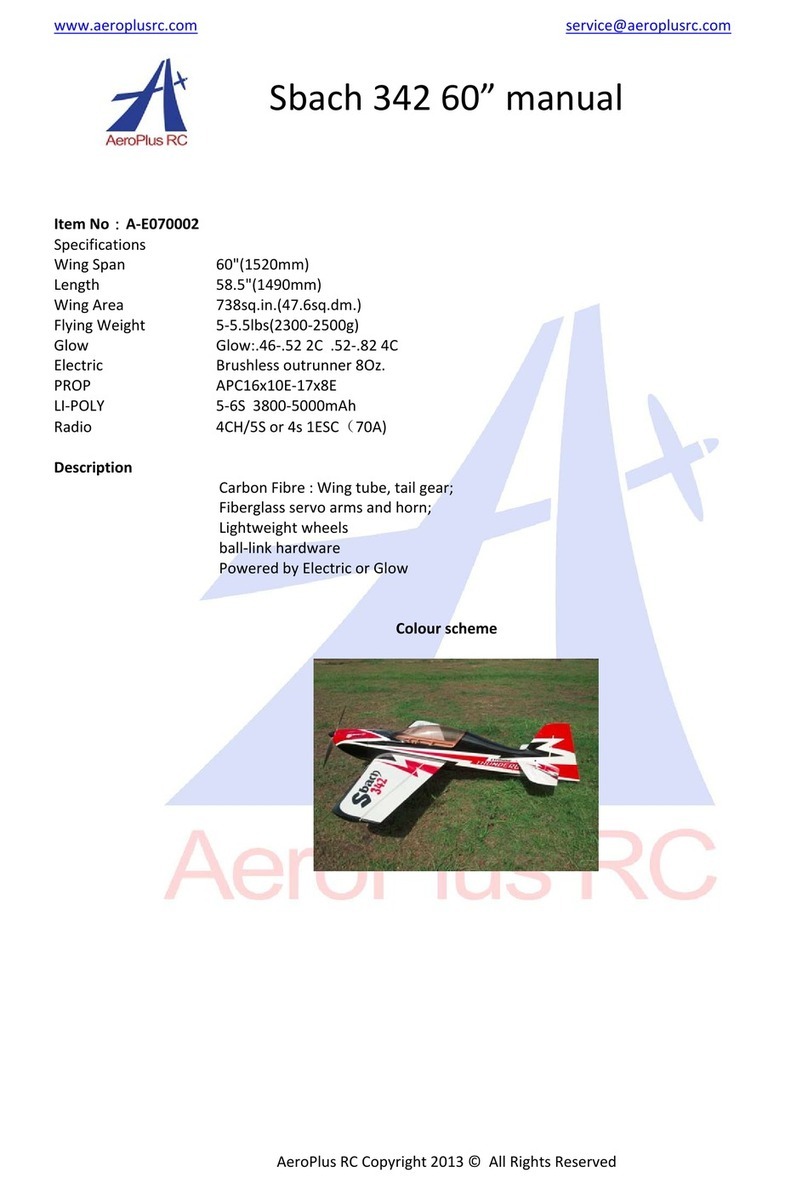

Sbach34220CC

ItemNo:A‐G020004

Specifications

WingSpan 68in(1720mm)

Length 65"(1656mm)

WingArea 907sqin(58.5sqdm)

FlyingWeight 7‐7.7lbs(3200‐3500g)

Glow 75‐.91(2C).91‐1.10(4C)

Gasoline 20‐26cc

Electric BRUSHLESSMOTORA5030

Radio 4CH/5‐6servos

Description

CarbonFiberwingtube,landinggear,tailgear;

Fibreglassservoarms,hornandreinforcedU/Cmounting

Scalereaddeck

Adjustablepushrods

Ringedcowl

Predrilledhinges

Colourschemes

A‐G020004A

www.aeroplusrc.com[email protected]

AeroPlusRCCopyright2013©AllRightsReserved

Unpacking

Carefullyunpackthemodelmakingsurethatifyouuseasharpknifetoopenbags,nottocutanycoveringonthe

model.Inspecteachitemtomakesurenotransitdamagehashappened.Ifyouarenothappywithanypartor

areunsurepleasecontacttheDealerthatyoupurchasedfrom.

Covering

Duetothemodelspendingtimeindifferentclimateszonesfromthefactoryonitswaytoyou,someofthe

coveringmayhavewrinkles.Wehighlyrecommendthatyoutaketimetore‐sealallcoveringedgeswithaniron

andtouseaheatguntoremoveanywrinklesandre‐tightenthecovering.Itisbesttodothisnowwhiletheplane

isnotassembled,remembertonotletanyheatgetnearanypartslikethecanopyorcowlasthismaycause

damage.

AssemblyTips

Wealsorecommendthatyougooveralltheaccessiblejointswithcyanoglue.Wickglueintoareasofhighstress

aroundtheU/Cplateandmotorbox.

UseNutlockonallmetaltometaljoints.Evenifyouareusingelectricwithlowvibrationlevelsitwillmakesure

thatthingsdonotdropoffyourairplane!!

www.aeroplusrc.com[email protected]

AeroPlusRCCopyright2013©AllRightsReserved

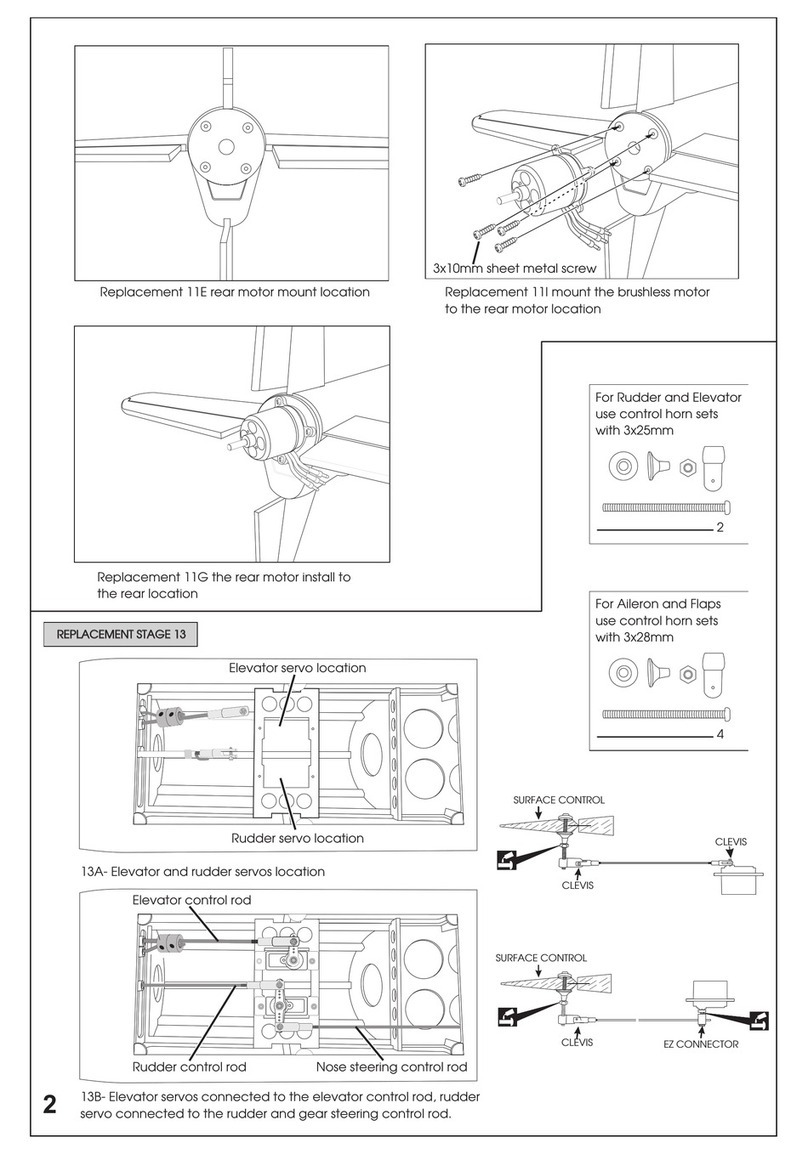

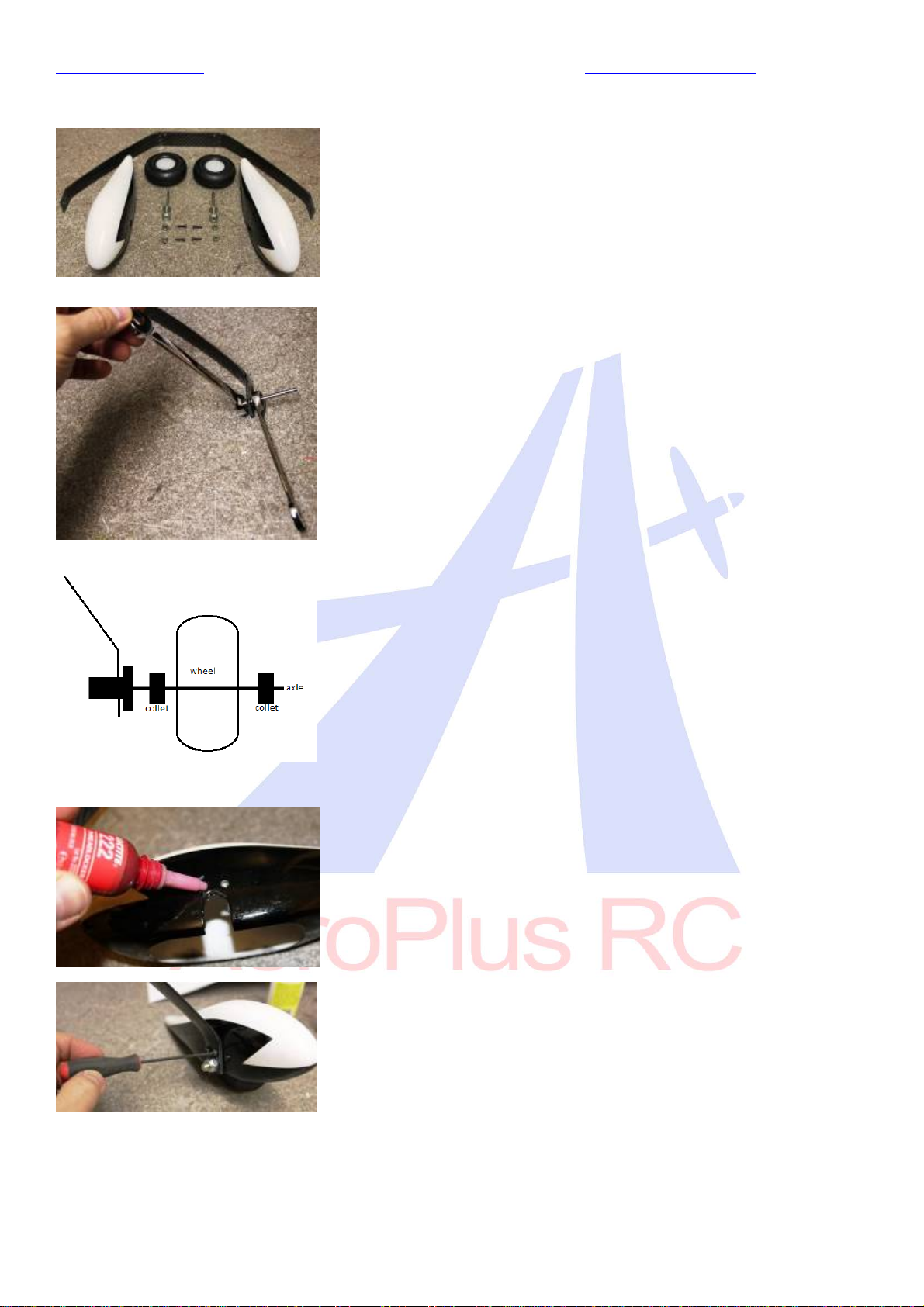

LandingGearAssembly

Tostopthefuselagegettingdamagedwhilethemodelisassembledwerecommendfittingthelandinggearfirst.

Pusheachaxlethroughthelargeholesandtightenupusing2spanners.

Placeacolletontheaxlefollowedbythewheel,thenanothercolletontheoutsideasperbelowdiagram.

Donottightenupthecolletsyetasthewheelneedstobefittedanequaldistancewithinthewheelpant.

TheU/Crakesforwardsousethecorrectwheelpantperside.Putnutlockontothe2xfactoryfittedblindnutsonthewheelpant

Fitovertheaxleandsecurewith2xcapheadbolts

Nowlineupthewheelinthecentreofthewheelpantopeningandtightenthecollets.Remembertousenutlockandtomakesurethewheelcan

movefreely.

Parts

CFLandingGear

2xwheelpants

2xwheels

2xaxles

4xcollets

4xM3bolts

www.aeroplusrc.com[email protected]

AeroPlusRCCopyright2013©AllRightsReserved

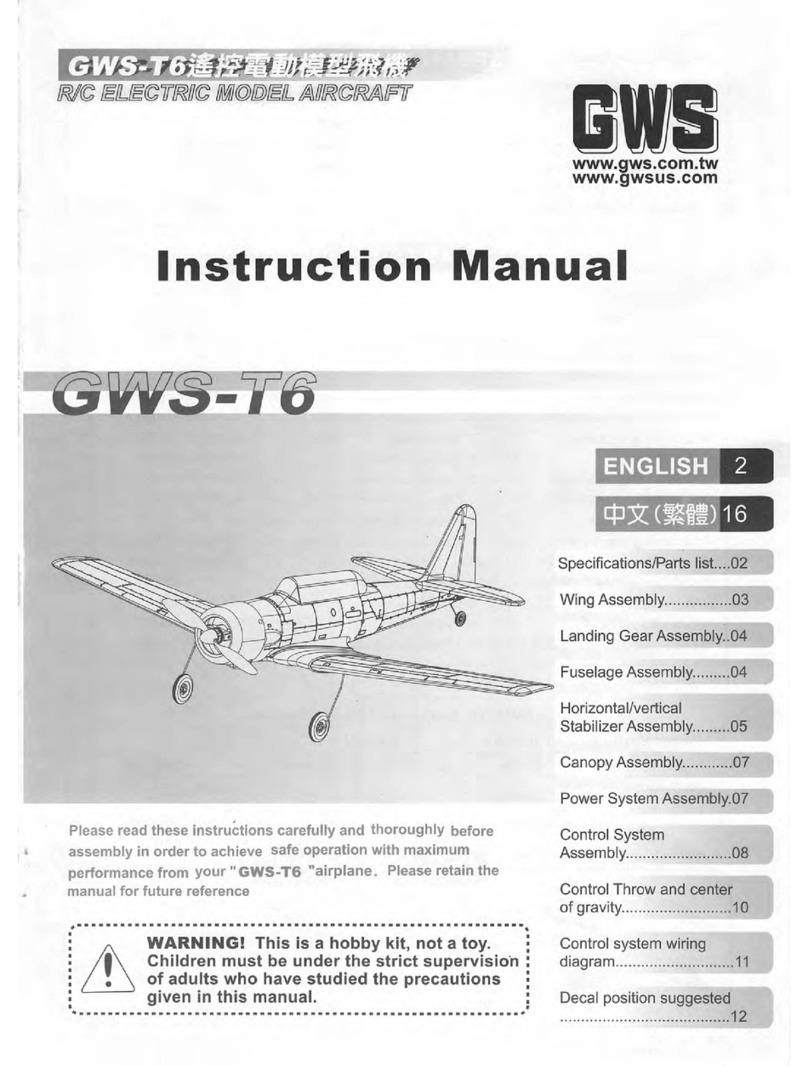

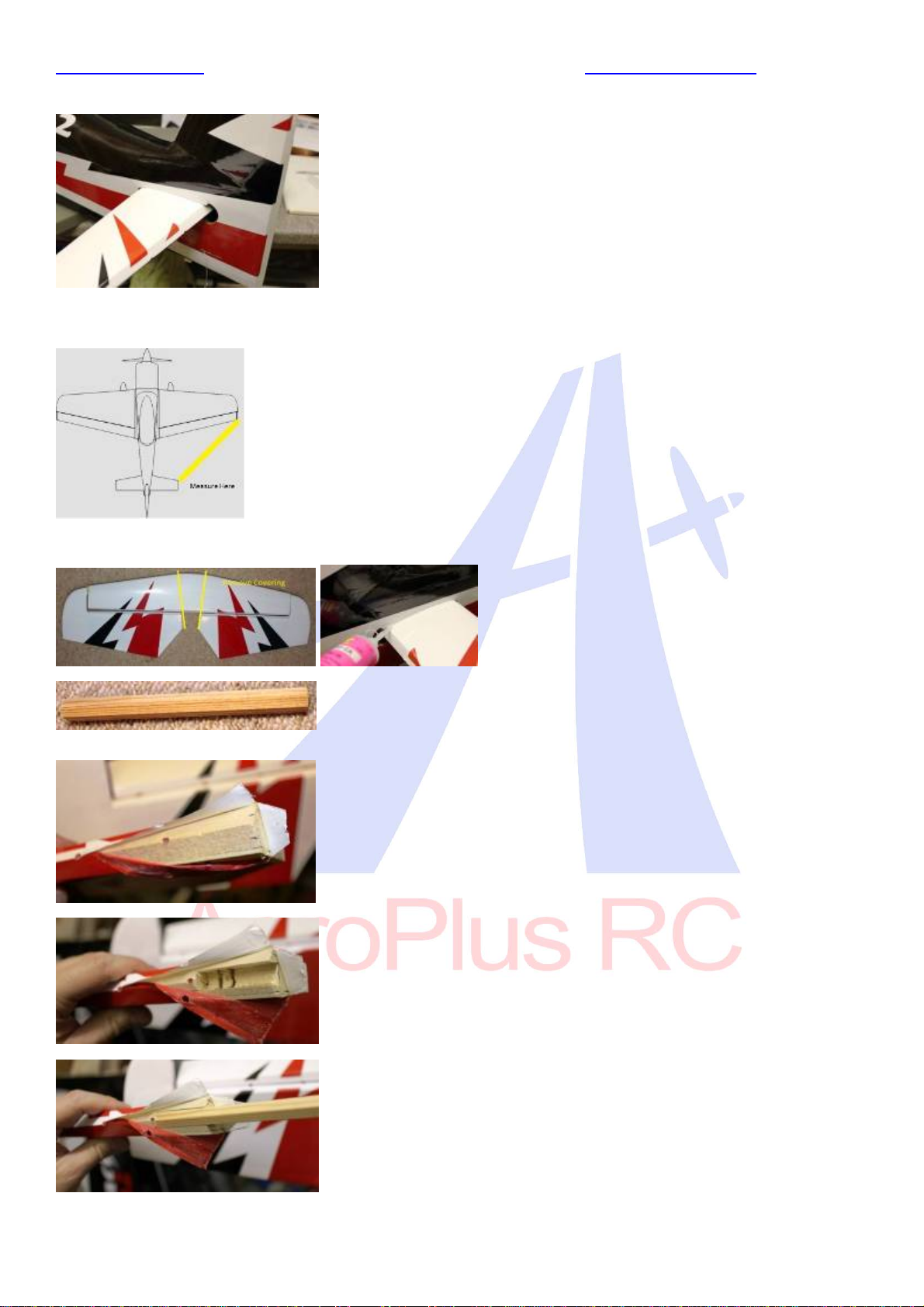

RearStab

Removetheelevatorsandhingesfromtherearstabandplaceitintheopening.

Itisimportantthatcareistakenwhenaligningtherearstab.Measureeachsidetomakesurethatanequalamountshowsoneachside.

FittheCFwingtubeandlookingfromthefrontandbackcheckthattheelevatorplateisinhorizontalalignmenttotherearstab.Ifitisnotthentrim

theopeningsothatitisequal.

Fitthewingsandmeasurefromtheendofthewingtotheelevatorstabtomakesurethatbothsidesareequal

Glueing–Onceyouthinkyouarereadytoglue,measureagain.Werecommend2methodsforgluing.Eitherremovethecoveringontheareathatis

coveredbythefuselageandgluewithepoxyorleavethecoveringonandgluewiththincyno.Wickinginthinfirst,ifalargegapisvisiblethenuse

mediumorthick.Remembertowickinsmallamountsatatimekeepingtheplanelevel,thiswillensurethegluestayswhereitneedstobe.

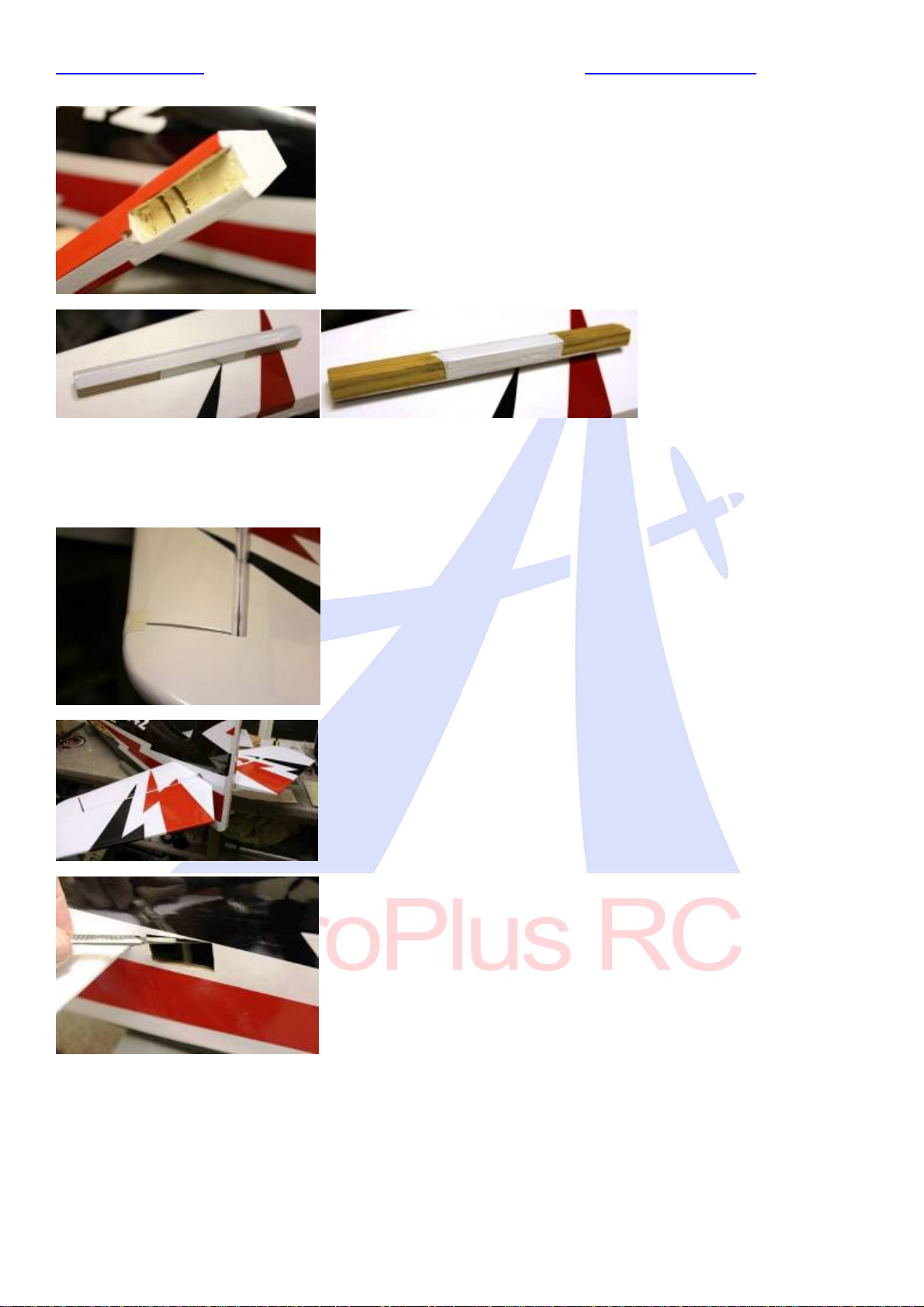

Dependingonifyouarefitting1or2elevatorservo’syoumayneedtofittheelevatorjoiningbar.

Workouthowmuchofthejoinerbarneedtogointotheelevatorhalfbylayingthebaroverthehalvesandsettingthesamelengthastherearstab.

Openupthecoveringattheinsideofeachoftheelevatorhavesandmarktheareaofwoodthatneedstoberemoved.

Cuttheareaofwoodawaywithasharpknife

Testfitthejoinerbar

www.aeroplusrc.com[email protected]

AeroPlusRCCopyright2013©AllRightsReserved

Ironbackdownthecovering

Coverthejoinerbarleavingtheglueareaexposed

Cuttheareaforthejoinerbarontheotherelevatorhalf,irondownthecoveringandtestfit.

Gluethejoinerbarinto1oftheelevatorhalveswithepoxy.

Nowwecanhingeoneoftheelevatorswiththejoinerbargluedin.

Apply‘vaseline’tothehingepointonthehingesandusing30minuteepoxytogluetheseintotheboththestabandelevatorhalf.Wipeoffexcess

gluebeforeitsets.

Dryfittheotherelevatorhalfwiththehingesandmakesurethatbothhalvesaligntothestab.Trimwherethejoinerbarsitsifrequired.

Gluethehingesinbothstabandelevatoragainwith30minuteepoxy.Whilegluingusetapetokeepitinalignment

Completedelevator

Removethecoveringfortheelevatorservo

www.aeroplusrc.com[email protected]

AeroPlusRCCopyright2013©AllRightsReserved

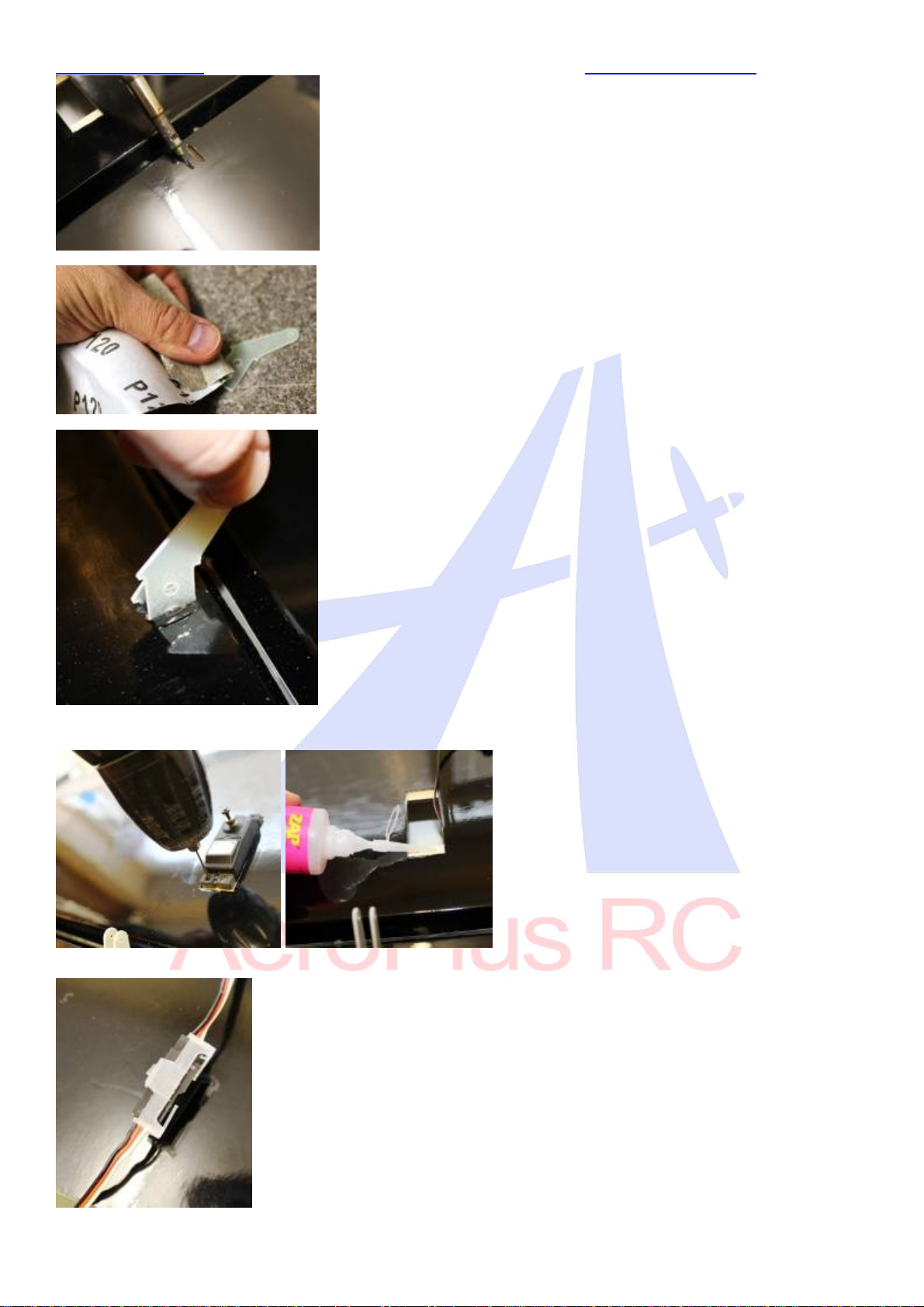

Removethecoveringwheretheelevatorhornsfit,useeitherasolderingironorasharpknife.

Testfitthehorns

Theareaonthehornsthatgoesinsidetheelevatorneedstoberoughedupwithsandpaper.Thisallowsabettergluejoint.

Gluethehornsinplacewithepoxyglue.Putaboltthroughtheballjointholetomakesurethatthehornsstayinalignmentwhiledrying.

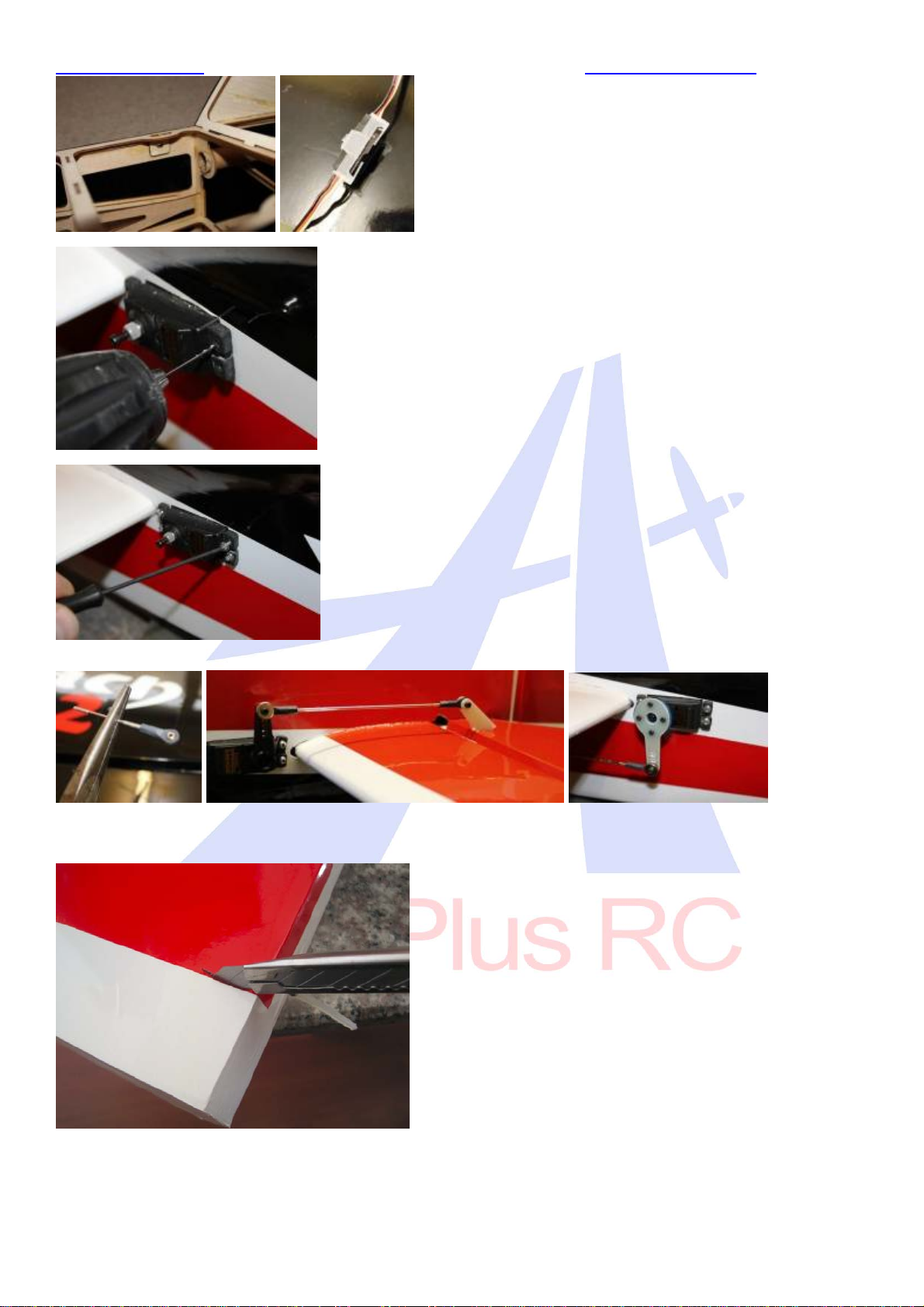

Beforefittingtheelevatorservofixanextensionleadsothatthewirecanberoutedthroughthecardboardtubewireholderinthefuselage.Onthe

servoleadjointaddaservoplugclip.

www.aeroplusrc.com[email protected]

AeroPlusRCCopyright2013©AllRightsReserved

FittheElevatorServoservoandusingafinedrill,drillholesfortheservoscrews.Removetheservoanddropthincynointoall4holes.

Re‐fittheelevatorservoandsecureitinwithservoscrews.

CentretheservousingyourTX,andfitaservoarm.Useeitheranaftermarketarmorattachthearmsthatweresuppliedtoaservohead.Screwball

jointsontothepushrod(useplierstoholdpushrod)andboltinplacewithsuppliedbolts.Centreofservoshouldalignwithelevatorflattothestab.

Ifyouareusingdualelevatorservosthenrepeattheprocessontheotherside.

Rudder

Removethecoveringwheretherudderhornspushthroughwitheitheraknifeorsolderingiron.

Testfittherudderhorns

www.aeroplusrc.com[email protected]

AeroPlusRCCopyright2013©AllRightsReserved

Sandtheareaonthehornthatfitsinsidetheruddersothegluebondsbetter

Gluetherudderhingesintoboththerudderandfinusingepoxyglue.Remembertousevaselineonthehingejoint.Whiledryingusetapetokeepit

inalignment.

Gluetherudderhornsthroughtherudderwithepoxy,wipeoffexcessgluewhileitiswet.Usetheballjointandboltwhilegluingtomaintain

alignment.Whilestillmovablemeasurethatthesameamountpushesouteachside.Careneedstobetakenhereotherwiseyourruddergeometry

willbeincorrect.

Assembletherudderservocontrolarmasbelow,drillholesforscrewsandusecynotostopthenutsfromcomingloose.

www.aeroplusrc.com[email protected]

AeroPlusRCCopyright2013©AllRightsReserved

Fittherudderservoanddrillholesusingafinedrillfortheservoscrews,dropthincynointotheholestostrengthenthewood.

Usingservoscrewsfixtheservoinplace,notethesplineistowardsthefrontoftheplane

Theclosedloopwiresareassembledintheplane;attachtherearballjointstotherudder.Dothistobothsides.(Sbach20CCusedsinglehorn)

Fitthearmontotherudderservoandcrimpthewirestoatauttension

TailGear

Locateallpartsasinpicture,whenassemblingremembertonutlockallparts

www.aeroplusrc.com[email protected]

AeroPlusRCCopyright2013©AllRightsReserved

AssembletheGearasperphoto

Attherearofthefuselageyouwillfindaplywoodarea,laytheCFgearonthisandmarkthe3holes.Takingcaretomakesureitisstraight.

Drilleachholewithafinedrillanddropthincynointotheholestostrengthenthewood.

ScrewtheCFgearonwiththethreesuppliedselftapingscrews.

Drillaholeinthebaseoftherudderfortheruddersteeringguide.

Beforegluingwithcyano,placeitoverthethinrod.

AileronServos

Theaileronsonthewingsarepre‐glued.Checkeachonebygentlypullingtomakesurethattheyaresecure

Removethecoveringwheretheaileronhornsaregluedinplace.Useeitherasolderingironorasharpknife

www.aeroplusrc.com[email protected]

AeroPlusRCCopyright2013©AllRightsReserved

Usingsandpaperroughtheareathatwillbegluedintotheaileron.

Gluebothhornsinwithepoxyglue,useaboltthroughthehornswhengluingtomakesurethealignmentiscorrect.

Fittheaileronservoanddrillfineholeswheretheservoscrewswillfit.Thenapplythincyanotostrengthentheholes.

#(Sbach20CCusedsinglehorn)

Ifrequiredinstallaservoextensionleadontotheservo,remembertouseaservoplugclip.

Fittheservoandcentretheservoarm.

www.aeroplusrc.com[email protected]

AeroPlusRCCopyright2013©AllRightsReserved

#(Sbach20CCusedsinglehorn)

Usingthepushrodsuppliedscrewballjointsontoeachend.Thecorrectlengthwillleavetheaileronlineduptotheinnerpartstillattachedtothe

wing.

Usingsuppliedboltsattachthepushrodatbothends.Checktoseeyouhavesufficientmovementoftheaileron.Ifnotadjust.

#(Sbach20CCusedsinglehorn)

Carryoutthesameprocedureontheotherwing.

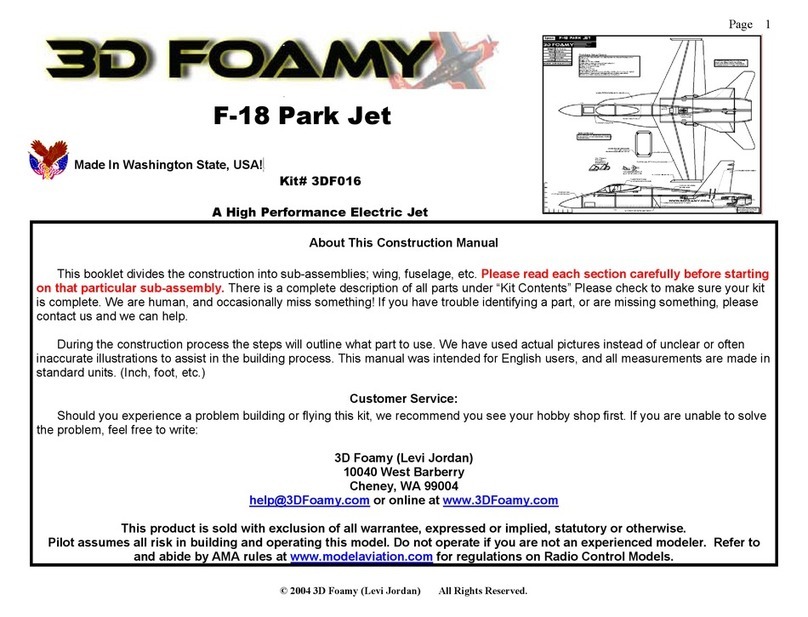

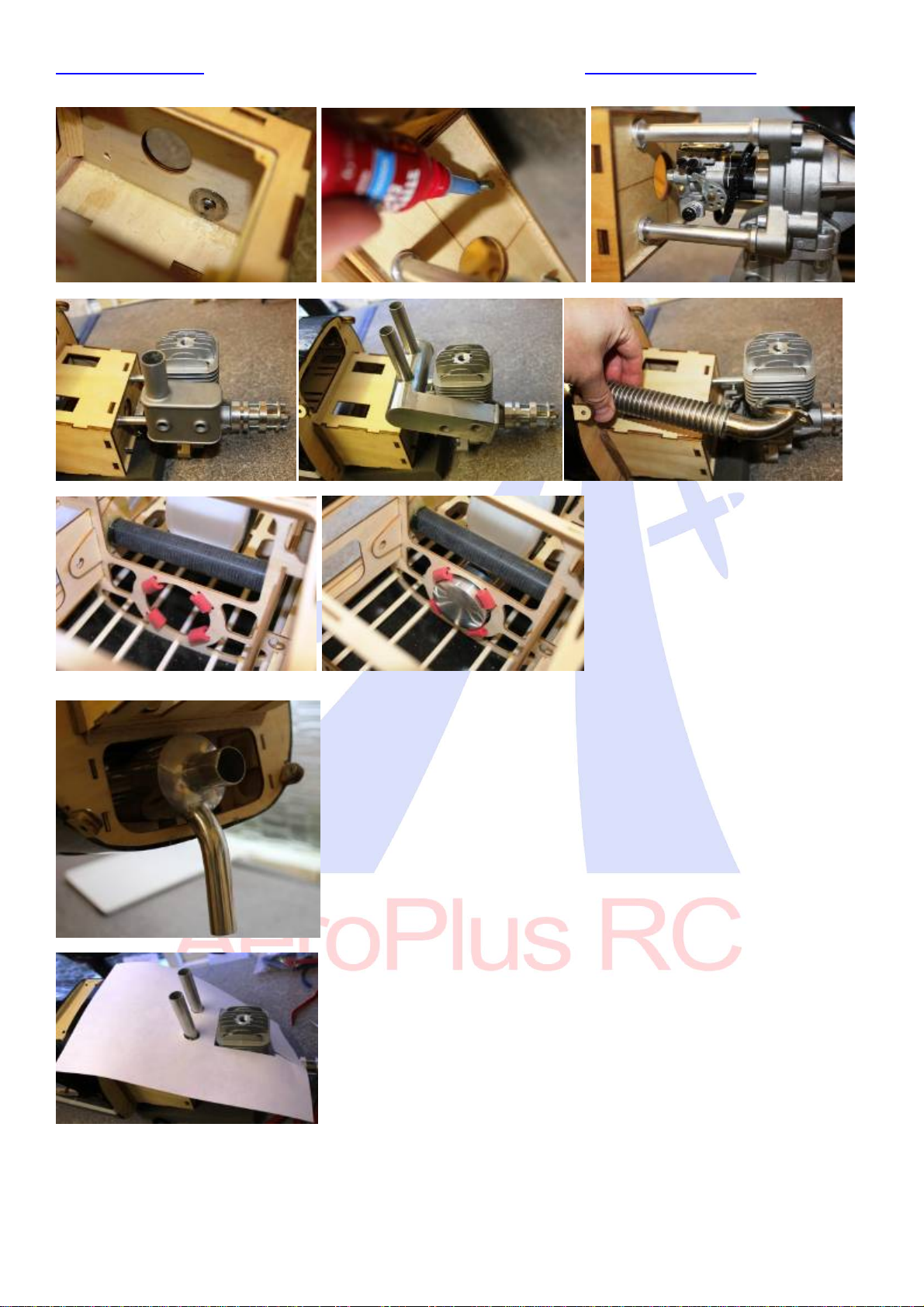

GasEngine

Fromthetemplatethatcamewiththeengine,usingthecrossaxisontheengineboxmarkthemountingholes.

Checkthediameteroftherequiredboltsanddrillaccordingly.

www.aeroplusrc.com[email protected]

AeroPlusRCCopyright2013©AllRightsReserved

Mounttheenginewiththestandoffstothebulkhead.Remembertouselargewashersontheinsidetospreadtheloadanduseplentyofnutlock.

Exhaustoptions.Dependingontheenginemanyexhaustoptionsareavailable.Standardmuffler,PittsExhaustofcanisterwithheader.

Ifusingacanisterabracketisalreadyinsidethemodel.Usingsilicontubingitwillholdtheendofthecanister.

Thefrontoutletofthecanisterwillpopoutofthebottomofthecowl

Cutouttheareafortheenginecylinderheadandtheexhaustoutletonapieceofthincardandtapethistothefuselageatoneend.

www.aeroplusrc.com[email protected]

AeroPlusRCCopyright2013©AllRightsReserved

Removetheengineandfitthecowl,thenfoldthecardbackover.

Marktheareaandcutoutusingadremel.Ensurethatenoughaircangetoutofthecowl.Therationisusually,3timeoutto1in.

Fittheignitiononthesideofthemotorbox.UseVelcroandalsoastraptoensureitdoesnotcomeoffwithvibration.

Thecowlisfixedin4places,2atthetopand2atthebottom.Placemaskingtapeoverthebottom2andpiercewheretheblindnutholeis.

Refitthecowlanddrillwherethemarkedholewas.

Thefueltankispre‐installed.Attachpetrolproofpipeasperlabellingontank

Usethesuppliedpushrodwithaballjointtoconnecttothethrottlearmontheengine.Thenfindaconvenientplacetolocatethethrottleservo

usingthesuppliedmount.

Installtheengineboxcoverplateonceallconnectionshavebeenmadefortheengine.

www.aeroplusrc.com[email protected]

AeroPlusRCCopyright2013©AllRightsReserved

Electric

Assemblethesuppliedelectricmotorboxandbolttotheenginebulkhead.

Dependingonthelengthofyourmotoryoumayneedtousethesuppliedroundplywoodspacerstoachievethecorrectlengthforthemotor.

MounttheESCinairflowonthesideoftheelectricmotormount,usingavelcostrap.

Withtheremovalofthefueltankitleavesalargeareawherethebatteriescanbemounted.

Switch

Oneachsideofthefuselagenearthecanopyboltsareareasforswitchestobemounted.

RX

AconvienientplacetomounttheRXisjustinfrontoftherudderservo.Ensurethatitismountedonvelcoandstrappeddown.

www.aeroplusrc.com[email protected]

AeroPlusRCCopyright2013©AllRightsReserved

Canopy

Thecanopyisheldinplacewiththe2thumbscrews,ensurethesearetightbeforeflying

Set‐up

Wehighlyrecommendtheuseofbothdualratesandexponential.Thiswillallowthemodeltoflybothprecisionand3Dattheflickofaswitch.

LowRates ExponentialHighRate Exponential

Elevator15‐20deg 15‐20% 35‐45deg 45‐60%

Ailerons15‐20deg 15‐20% 35‐45deg 45‐60%

Rudder25‐30deg 15‐20% 35‐45deg 45‐60%

Fortestflightsalwaysuselowrates,rememberthat+and–exponentialisdifferentpermanufacturer,checkyourTXmanual.

Alwayschecktherangeonyourmodelbeforethemaidenflight.Carryoutashortflightthengoovereverythingtomakesurenothinghascomeloose.

CGLocation

WesuggestforinitialtestflightssettheCG116mmor4inchesfromtheleadingedgeofthewing.

Adjustafterfirstflightstopersonalpreference.

This manual suits for next models

1

Table of contents

Other AeroPlus Toy manuals

AeroPlus

AeroPlus EXTRA 330SC 60CC User manual

AeroPlus

AeroPlus Corvus Racer 540 User manual

AeroPlus

AeroPlus Edge 540 V3 35CC User manual

AeroPlus

AeroPlus MXS-R 30CC User manual

AeroPlus

AeroPlus Sbach 342 User manual

AeroPlus

AeroPlus Extra 330LT User manual

AeroPlus

AeroPlus YAK 55M User manual

AeroPlus

AeroPlus Corvus Racer 540 59 User manual

AeroPlus

AeroPlus A?G030010A User manual

AeroPlus

AeroPlus Edge 540 V3 20CC User manual